37

6. Inspection/Maintenance

6.2.8

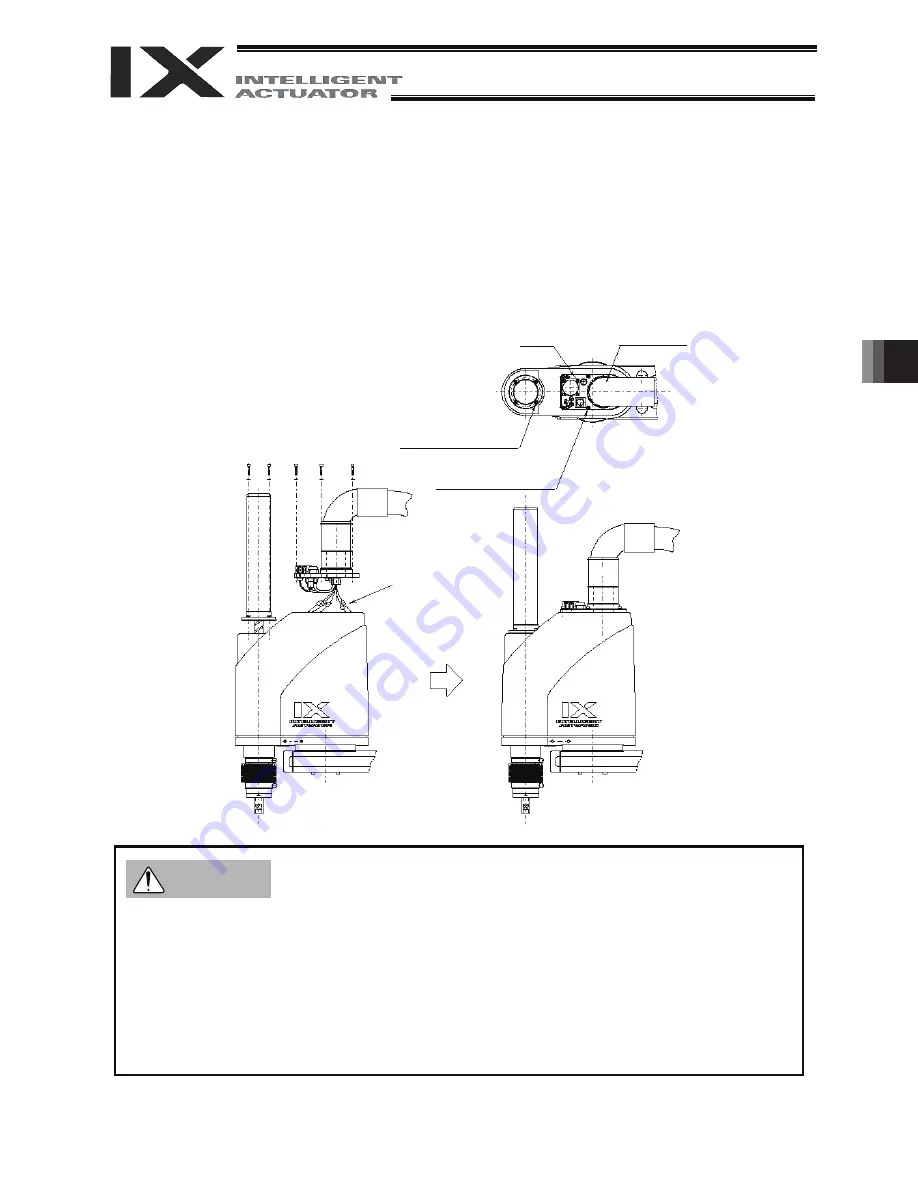

Installing the Cover

(1) Install the cover and connect the motor connectors (M, PG, BK) extending from the rotary joint.

(2) Affix the panel using the six cap screws (M3 x 18) [1] to a tightening torque of 0.08 kgf

m by paying

attention not to cause the wires to rest on top of one another.

(Place the wires neatly in the upper space without letting them rest on top of one another. Do not

forcibly tighten the screws with the panel still floating.)

(Don’t forget to insert a sealing washer.)

(3) Tighten the four cap screws (M3 x 18) [2] to a tightening torque of 0.08 kgf

m to affix the dust cover.

(Don’t forget to insert a sealing washer.)

z

Check the marking tubes to prevent improper connections.

z

Be careful not to bend the air tubes.

z

Be careful not to pinch the cables.

z

Place the wires neatly in the upper space without letting them rest on top of one another. Do not

forcibly tighten the screws with the panel still floating.

z

Check if the connectors are fully inserted.

z

If the cover is removed, absolute reset must be performed again for the rotational axis and vertical

axis. (See 6.4, “Absolute Reset Procedure.”)

Rotary joint

Panel

Caution

[2] CAP 4 - M3 x 18

(with sealing washer)

Connect the motor

connectors.

[1] CAP 6 - M3 x 18

(with sealing washer)

Summary of Contents for Intelligent Actuator IX Series

Page 2: ......

Page 55: ...49 6 Inspection Maintenance 6 Click the Servo OFF button 7 Press the emergency stop switch ...

Page 75: ......