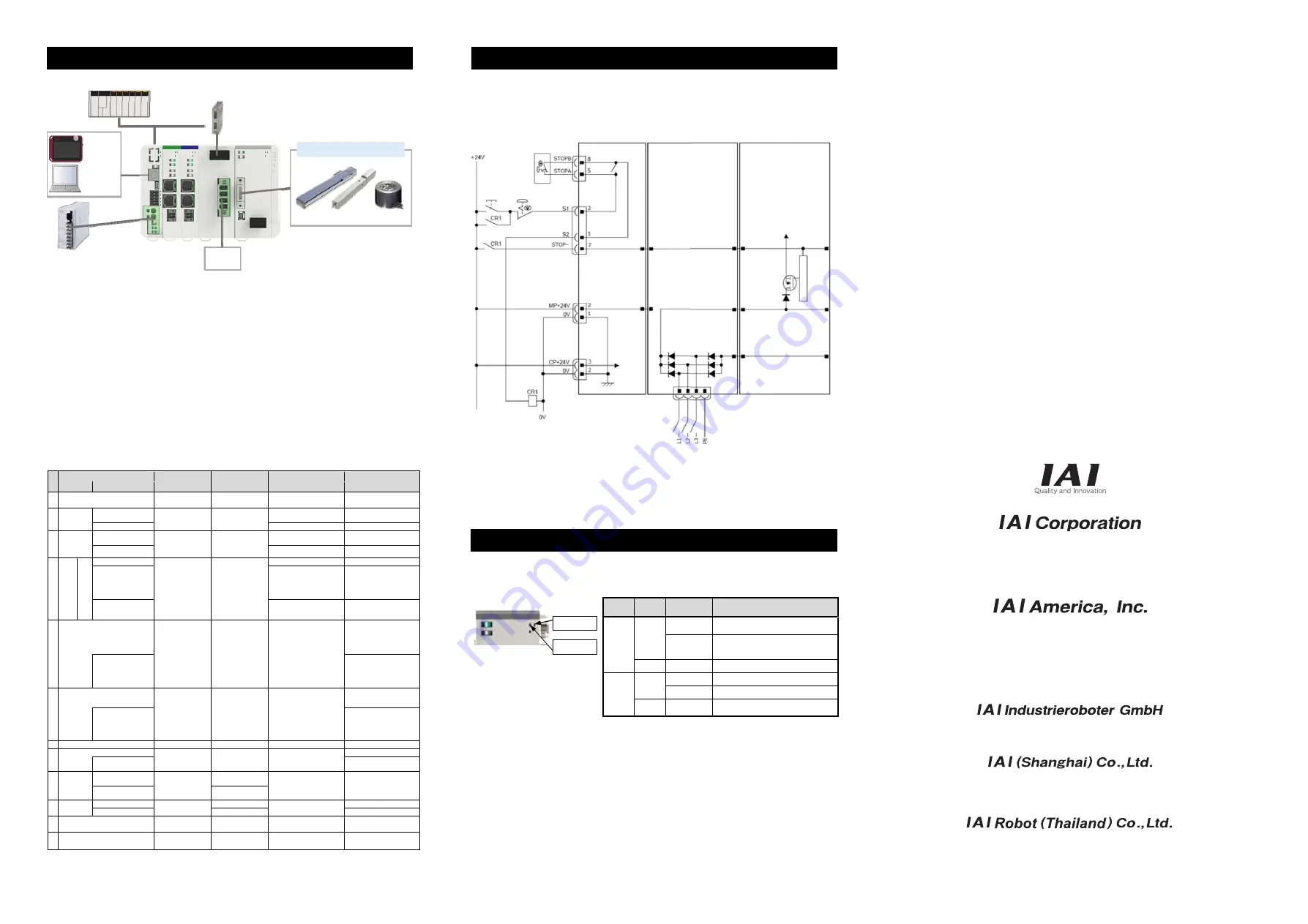

Wiring Layout for Motor/Encoder Cables

Note 1 The 200V Servo Motor Actuators below are not capable to be connected to the 200V Driver Units.

(1) Motor types other than those from 60W to 750W

(2) Encoder types other than Battery-less Absolute, Incremental, Spurious Absolute and Index Absolute

(3) For Three-phase 200V, combination that exceeds 2400W in total of Actuator Wattages connected to

200V Driver Units

(4) For Single-phase 200V, combination that exceeds 1600W in total of Actuator Wattages connected to

200V Driver Units

(5) Servo Pressing Type

(6) SCARA Robot

(7) CT4 Series

(8) ZR Series

When it is necessary to connect actuators from (1) to (4) above, use the SCON Extension Unit and

SCON-CB.

Also, DD/DDA and LSA-W21S are not conformed with Single-phase 200V

Note 2 There is a built-in regenerative resistor of 60W equipped in 200V Driver Unit and 200V Power

Supply Unit.

The regenerative resistor is basically not necessary, but use this External Regenerative Resistor

Unit in case of shortage in regenerative resistance.

200V Driver Unit Connection Cable List

No.

Actuator

Series

Target type

Motor cable

Motor robot cable

Encoder cable

Encoder robot cable

(1)

RCS4

RCS4CR

CB-RCC1-MA□□□

CB-X2-MA□□□

―

CB-X1-PA□□□

(2)

RCS3(P)

RCS3(P)CR

CTZ5C

CT8C

CB-RCC1-MA□□□

CB-X2-MA□□□

―

CB-X1-PA□□□

Those other than above

CB-RCS2-PA□□□

CB-X3-PA□□□

(3)

RCS2

RCS2CR

RCS2W

RTC□L

RT6

CB-RCC1-MA□□□

CB-X2-MA□□□

CB-RCS2-PLA□□□

CB-X2-PA□□□

Those other than above

CB-RCS2-PA□□□

CB-X3-PA□□□

(4) RCS2

with

no

loa

dc

el

l

eq

ui

ppe

d

RA13R

CB-RCC1-MA□□□

CB-X2-MA□□□

CB-X2-PLA□□□

CB-X2-PLA□□□

RA13R

with brake

(with brake box)

[Between Actuator and

Brake Box]

CB-RCS2-PLA□□□

[Brake Box and controller]

CB-RCS2-PLA□□□

[Between Actuator and

Brake Box]

CB-X2-PLA□□□

[Brake Box and controller]

CB-X2-PLA□□□

RA13R

with brake

(with no brake box)

[Between Actuator and

Brake Box]

CB-RCS2-PLA□□□

[Between Actuator and

Brake Box]

CB-X2-PLA□□□

(5)

IS(P)B

IS(P)DB

IS(P)DBCR

―

CB-X2-MA□□□

―

CB-X1-PA□□□

*

For cable length 21m or

more and 30m or less in

battery-less absolute type;

CB-X1-PA□□□-AWG24

Option:

with limit switch type

CB-X1-PLA□□□

*

For cable length 21m or

more and 30m or less in

battery-less absolute type;

CB-X1-PLA□□□-AWG24

(6)

IS(P)A

IS(P)DA

IS(P)DACR

SSPA

SSPDACR

IF

FS

RS

―

CB-X2-MA□□□

―

CB-X1-PA□□□

Option:

with limit switch type

CB-X1-PLA□□□

(7) NSA

―

CB-X2-MA□□□

―

CB-X1-PA□□□

(8) NS

―

CB-X2-MA□□□

―

CB-X3-PA□□□

Option:

with limit switch type

CB-X2-PLA□□□

(9)

DD(A)

DD(A)CR

DDW

T18□

LT18□

―

CB-X2-MA□□□

―

CB-X3-PA□□□

H18□

LH18□

CB-XMC1-MA□□□

(10) LSA

W□□□

―

CB-XMC1-MA□□□

―

CB-X2-PLA□□□

Those other than above

CB-X2-MA□□□

CB-X3-PA□□□

(11) LSAS

―

CB-X2-MA□□□

―

CB-X1-PA□□□

(12) IS(P)WA

―

CB-XEU1-MA□□□

―

CB-X1-PA□□□-WC

Power Supply and Stop Circuit (Example)

In the diagram below shows a circuit related to RCON drive source cutoff. The 200V Motor Power Supply is

a supply to the 200V Power Supply Unit. The circuit related to the drive-source cutoff is on the driver unit

side.

Each driver unit possesses a drive source cutoff circuit by semiconductor. The motor power should be

cut off by STOP Signal. The drive source cutoff circuit by semiconductor possesses features to detect

the overcurrent and to limit the in-rush current.

Note 1 RCON-GW : If nothing is connected to the SIO connector, S1 and S2 will be short-circuited in the controller.

RCON-GWG : If nothing is connected to the SIO connector, S1 and S2 will not be short-circuited in the controller.

To short-circuit, connect the supplied dummy plug DP-5 to the SIO connector.

Note

●

Consider the cable diameter and length that would not drop the voltage for the drive-source cutoff connector wiring.

●

There could be a case that the voltage drops on the controller power supply and generate an alarm due to the cable

diameter and length.

In such a case, adjust the output voltage on the power supply so the voltage supplied to the

controller is kept at 24V.

Troubleshooting (LED Display)

In this section, describes for LED.

Utilize them to check normal operation status and recovery after error occurrence.

(1) 200V Driver Unit

Panel

Display

Color

Status

Explanation

T RUN

GN

Illuminating Inside bus communication in

normal conditions

Flashing

Waiting for initializing

communication,

Initializing communication error

OR

Illuminating Inside bus communication in error

SYS

GN

Illuminating Turning servo ON

OFF

Turning servo OFF

RD

Illuminating Alarm being generated, STOP

signal input ON

Head Office: 577-1 Obane Shimizu-KU Shizuoka City Shizuoka 424-0103, Japan

TEL +81-54-364-5105 FAX +81-54-364-2589

website: www.iai-robot.co.jp/

Ober der Röth 4, D-65824 Schwalbach am Taunus, Germany

TEL 06196-88950 FAX 06196-889524

SHANGHAI JIAHUA BUSINESS CENTER A8-303, 808, Hongqiao Rd. Shanghai 200030, China

TEL 021-6448-4753 FAX 021-6448-3992

website: www.iai-robot.com

Technical Support available in USA, Europe and China

Head Office: 2690 W. 237th Street, Torrance, CA 90505

TEL (310) 891-6015 FAX (310) 891-0815

Chicago Office: 110 East State Parkway, Schaumburg, IL 60173

TEL(847) 908-1400 FAX (847) 908-1399

TEL (678) 354-9470 FAX (678) 354-9471

website: www.intelligentactuator.com

Atlanta Office: 1220 Kennestone Circle, Suite 108, Marietta, GA 30066

825 PhairojKijja Tower 7th Floor, Debaratana RD., Bangna-Nuea, Bangna, Bangkok 10260, Thailand

TEL +66-2-361-4458 FAX +66-2-361-4456

website:www.iai-gmbh.de

website:www.iai-robot.co.th

Manual No.: ME0397-1B

T RUN LED

SYS LED

Power Supply Cable

(Cables to be prepared by

customer)

* Use cable with diameter large

enough to accept current.

Field Network

Connectable Actuators

(Note 1)

PLC

Regenerative Resistances Unit

(Note 2)

RESU-2/RESUD-2

PSA-24

Power Supply

Unit

TB-02

TB-03

IA-101-X

IA-101-N

RCU-101-MW

RCM-101-USB

Single-phase

/Three-phase

AC200V

Gateway Unit

200V Power Supply Unit

200V Driver Unit

SIO Connector

System I/O

Connector

Motor Power Supply

Connector

for P/A/D Drivers

Control

Power

Connector

Note 1

Control

Power

Emergency

Stop Reset

Switch

Emergency

Stop Switch

Stop Switch on

Teaching Pendant

Motor Power Supply

Connector

M

ot

or

P

ow

er

S

uppl

y

Hi

gh-

Si

de

Pr

otec

tion

Ci

rcui

t