MAN-045 ING

8

4.

DISASSEMBLE THE CON-ROD WITH

WASHERS.

REPEAT THE OPERATIONS TO EXTRACT

THE CRANKPIN FROM THE OTHER HALF

CRANKSHAFT (see Fig.3).

BEFORE REASSEMBLING, WASH ALL PARTS WITH KEROSENE

a)

CHECK STATUS OF CON-ROD (TOP

AND BOTTOM) .

IF OVALIZATION EXCEEDS 0.01mm,

REPLACE CON-ROD.

-CENTESIMAL MICROMETER (21/50)

-BORE GAUGE WITH CHECK RING Ø24 and Ø16

b)

CHECK STATUS OF CRANKPIN.

VISUAL CHECK – REPLACE IF

NECESSARY BUT ALWAYS

AFTER MAX. 8 HRS WORKING

.

c)

CHECK STATUS OF ROLLER CAGE

(BIG END) VISUAL CHECK – REPLACE

IF NECESSARY BUT ALWAYS AFTER

MAX. 8 HRS WORKING.

d)

CHECK STATUS OF CRANKSHAFT

HALVES.

REPLACE IF BEARING SEAT IS BELOW

0.03mm VS NEW.

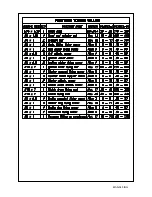

FOLLOW ATTACHED TABLE FOR MATCHING PLAYS

Fig.3