IAP Boxair M1002

www.IAP-AirProducts.com

- 7 -

MAINTENANCE

DAILY:

•

overall control for connection

tightness, including the state of

chamber door seals and flexible hoses

•

visual control of the filter wear (how to

•

access the filter cartridge - page 6)

MONTHLY:

•

visual inspection for signs of corrosion

•

electrical system and wire insulation

control

YEARLY:

•

filter cassette replacement

•

inspection for corrosion or any type of

mechanical perforation of the filter box

•

inspection of electrical wiring

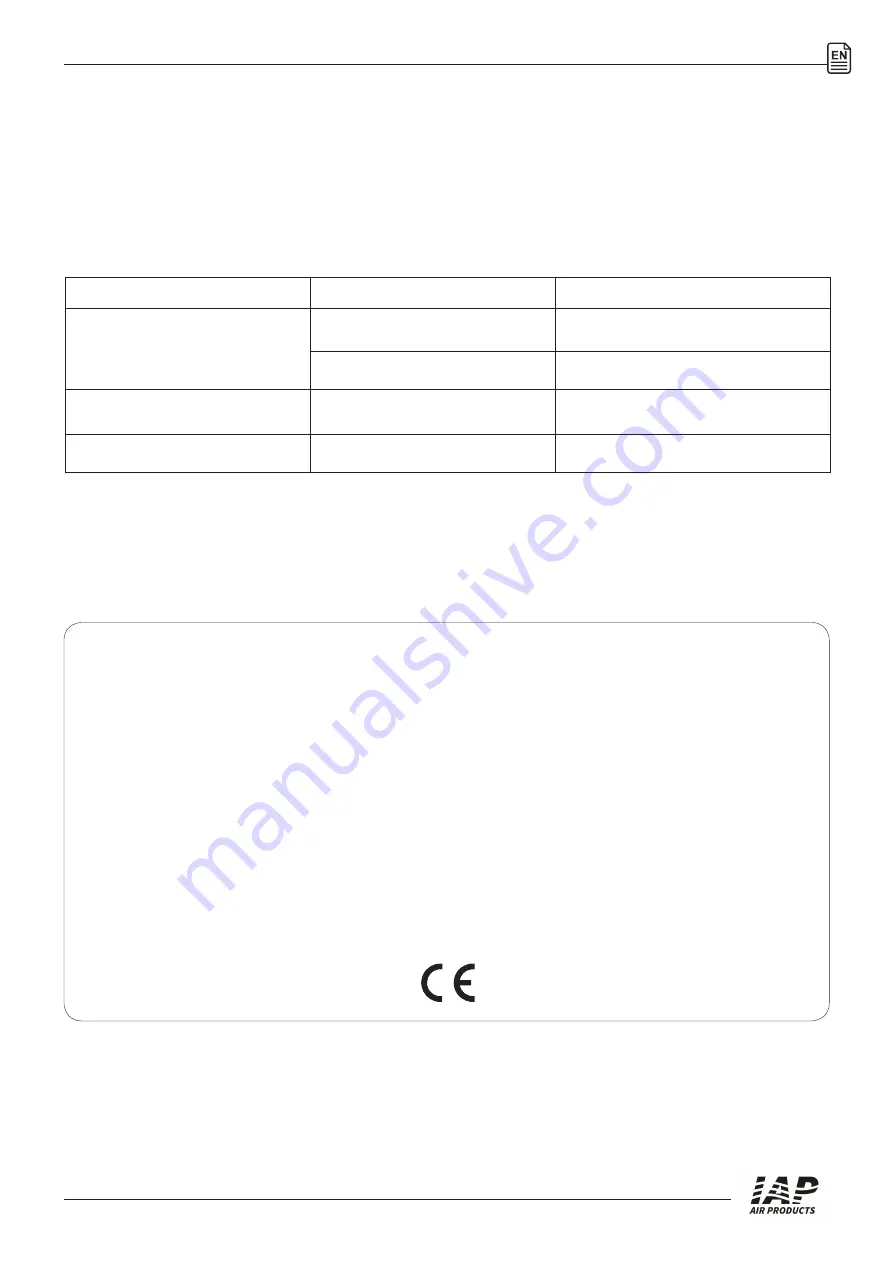

TROUBLESHOOTING

SYMPTOMS

POSSIBLE REASONS

PROCEDURE

Low air volume.

Filter cartridge is clogged.

Take out filter cassette and clean it. If this

proves ineffective replace with a new one.

Obstructed suction channel

Check the efficiency of channels and if

necessary clean them.

Dust coming out of the filter.

Wrong or mechanically damaged seal or

filter cassette.

Properly tighten the filter gasket.

Replace filter cassette with a new one.

Cannot start the

device.

No power supply.

Check the connection of the device, check the

power supply.

EC DECLARATION OF CONFORMITY

The manufacturer:

Industrial Air P

roducts

2544 Highway 70 East

Cookeville, TN 38506

Confirms the following product:

Boxair M1002 mobile filter unit

meets the requirements of the following European directives:

•

Directive 2006/42/EC of the European Parliament and the Council of 17 May 2006. on machinery and amending Directive 95/16/EC (recast).

•

Directive 2006/95/EC of the European Parliament and the Council of 12 December 2006 on the harmonization of the laws of the Member States relating

to electrical equipment designed for use within certain voltage limits.

and the following standards:

•

BS EN 60204-1:2010 Safety of machinery - Electrical equipment of machines - Part 1 General Requirements.

•

BS EN 12100-2:2005 / A1: 2009 EN Safety of machinery - General principles for design - risk assessment and risk reduction.

•

BS EN 13857:2010 Safety of machinery - Safety distances to prevent reaching the upper and lower limbs to hazardous areas.

•

BS EN 60034-1:2009 EN Rotating electrical machines - Part 1: Rating and performance