10

Check that

the control unit is connected as per instructions on page 9.

Input voltage 230-240 V +/-15%, 50/60 Hz.

Check that

the input signal is 0-10 V.

Check that

rotation monitor and cleaning function are connected.

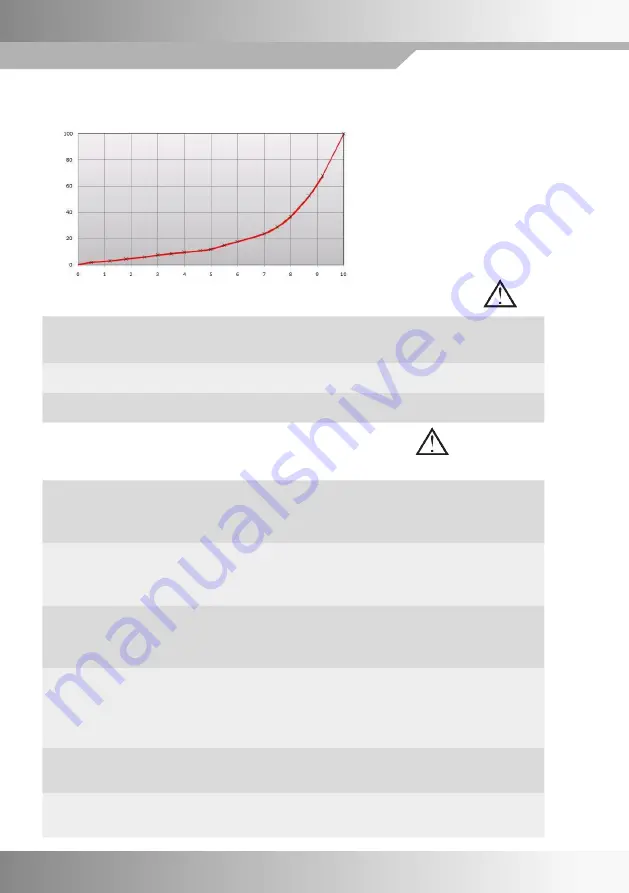

INPUT SIGNALS/ROTATION SPEED

The input signal is directly proportional

to the efficiency of the wheel, which

means that input signal and rotation

speed are as per adjoining diagram.

CHECKS BEFORE SWITCHING ON THE CONTROL UNIT

Check that

the motor rotates in the right direction in relation to the wheel's direction

of rotation.

In the event of a fault, switch two phases to the motor.

Adjustment of max.

speed

Set the DIP switch to "High speed" in the ON position.

Adjust "Max. speed" so that the wheel rotates at 10-12 rpm (or as per

directions from wheel manufacturer).

Checking minimum

speed

Set the DIP switch to "Low speed" in the ON position.

Check that the wheel starts.

The minimum speed is preset.

Checking the cleaning

function

Switch off the voltage.

Make sure that the "Cleaning" DIP switch is set to ON, and that the input

signal is disconnected.

After switching on the voltage the wheel rotates for 20 seconds at 12 rpm.

Checking the rotation

monitor

The yellow "Rotation" light diode should flash when the magnet passes

the magnetic sensor, whatever the DIP switch position.

Finish by

having the control unit drive the wheel at maximum and minimum

rotation speed and checking that the wheel speed is correct.

PUTTING THE EQUIPMENT INTO OPERATION

Should be done in sequence

11

Input signal 0-10 V

Input signal - rotation speed

Rotation speed [%]