AST1257-940

Page

28

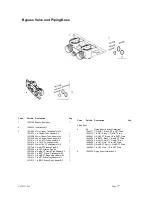

Troubleshooting

The technology upon which the Series 255/940

control is based, is well established and proven in

service over many years. However, should a problem

or question arise regarding the operation of the

system, the control can be very easily serviced. The

control module can be quickly replaced or

adjustments can be made at the installation. For parts

mentioned, refer to exploded views in the

Replacement Parts

section of this manual.

IMPORTANT:

Service procedures that require the

water pressure to be removed from the system are

marked with a

!

after the possible cause. To remove

water pressure from the system, put the bypass valve

or three-valve bypass into the bypass position and

open the Rinse Drain Valve (the fifth valve back from

the control) with a screwdriver, Figure 11. Restore

system water pressure when the service work is

completed.

Problem

Cause

Solution

1. Control will not

regenerate automatically

a. Electric cord unplugged

b. Defective Timer motor

c. Day pins not down on calendar

cap.

d. Binding in gear train of timer

a. Connect power

b. Replace motor

c. Depress pins for days regeneration

required

d. Replace timer

2. Control regenerates at

Wrong time of day

a. timer set incorrectly.

a. Correct setting according to

Instructions.

3. Control will not draw

Brine.

a. Low water pressure.

b. Restricted drain line.

c. Injector plugged.

!

d. Defective injector.

!

e. Valve disc 2 and/or 3 not closed.

f. Air check prematurely closed.

a. Water pressure must be 20 psi

minimum.

b. Remove restriction.

c. Clean injector and screen.

d. Replace injector cap.

e. Flush out foreign matter holding disc(s)

open by manually operating valve

stem(s). Replace if needed.

f. Put control momentarily into brine refill.

replace or repair air check if needed.

Refer to

Brine Line Connection.

4. Brine tank overflow.

a. Brine valve disc1 being held open

By foreign matter.

b. Uncontrolled brine refill flow rate.

c. Valve disc 2 and/or 3 not closed

During brine draw causing brine

refill

d. Air leak in brine line air check.

e. Improper drain control for injector.

a. Flush out foreign matter holding disc

open by manually operating valve stem.

b. Remove and clean brine refill flow

control.

c. Flush out foreign matter holding disc(s)

open by manually operating valve

stem(s).

d. Check all connections in brine line for

leaks. Refer to

Brine Line Connection.

e. Too small of a drain control with a "B"

or "C" injector will reduce draw rates.

Reference

Pressure Graphs.

5. System using more or

less salt than salt control

Is set for.

a. Inaccurate setting.

b. Foreign matter in controller

Causing incorrect flow rates.

c.

Defective controller.

!

a. Make correct setting

b. Remove salt controller and flush out

foreign matter. Manually position

control to brine draw to clean

controller. After so doing, position

control to "brine/slow rinse" to remove

brine from tank.

c. Replace defective part.

Summary of Contents for AST1257-940

Page 20: ...AST1257 940 Page 20 Control Valving Identification Valve Disc Operation...

Page 21: ...AST1257 940 Page 21 Flow Diagrams...

Page 22: ...AST1257 940 Page 22...

Page 24: ...AST1257 940 Page 24...

Page 25: ...AST1257 940 Page 25 Valve Body and Tank Adaptor Module...

Page 29: ...AST1257 940 Page 29...