INSTALLATION AND OPERATION INSTRUCTIONS

1-32

DC SERIES BOILERS / WATER HEATERS

DC 15-95, DC 15-96, DC 20-125, DC 33-160

GAS PIPING

The boiler / water heater should normally have an inlet gas pressure of at least

7.0" w.c. for natural gas and 11" w.c. for propane gas. For either fuel, the inlet

pressure shall be no greater than 14.0" w.c. Confirm this pressure range is

available with your local gas supplier.

The inlet gas connection of the boiler’s gas valve is 1/2" NPT (male).

Adequate gas supply piping shall be provided with no smaller than 1/2" Iron Pipe

Size (e.g. Iron Pipe Size (IPS) and using a 1" w.c. pressure drop, in accordance

with the following chart:

MODEL

1/2" IPS

3/4" IPS

1" IPS

DC Series (Natural Gas)

20'

70'

200'

DC Series (Propane)

50'

200'

600'

Table 7: Maximum Pipe Length (ft) – DC series 33-160 boiler

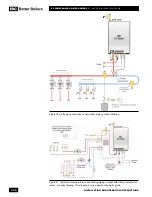

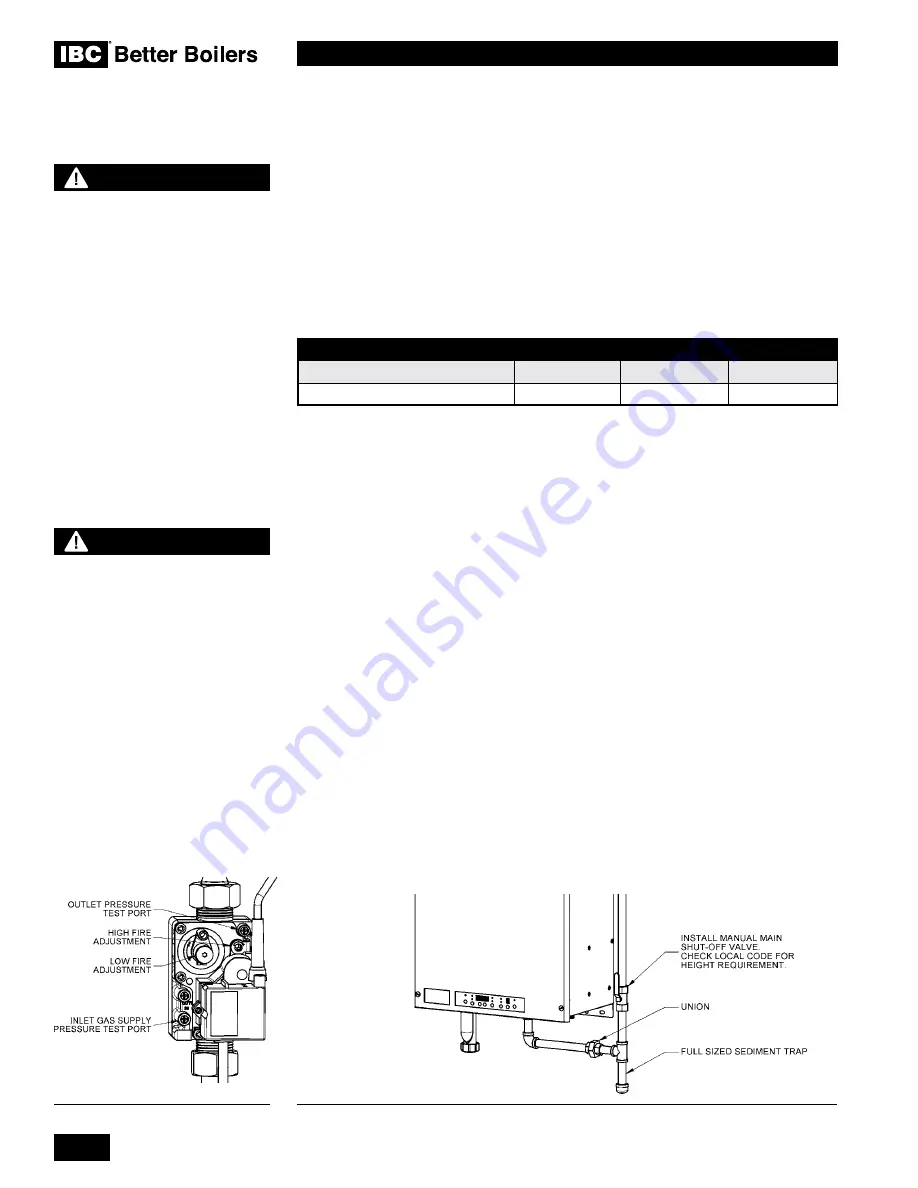

Gas piping must have a sediment trap ahead of the boiler / water heater’s gas

valve

(see Figure 32).

A manual shutoff valve must be located outside the boiler,

in accordance with local codes/standards. All threaded joints in gas piping should

be made with an approved piping compound resistant to the action of natural

gas/propane. Use proper hangers to support gas supply piping as per applicable

codes.

The boiler / water heater must be disconnected or otherwise isolated from the

gas supply during any pressure testing of the system at test pressures in excess

of 1/2 psig. Dissipate test pressure prior to reconnecting. The boiler / water

heater and its gas piping shall be leak tested before being placed into operation.

•

The boiler / water heater and its individual shutoff valve must be disconnected

from the gas supply piping system during any pressure testing of that system

at test pressures in excess of 1/2 psi (3.5 kPa).

•

The boiler / water heater must be isolated from the gas supply piping system

by closing, disconnecting and capping its individual manual shutoff valve

during any pressure testing of the gas supply piping system at test pressures

equal to or greater than 1/2 psi (3.5 kPa).

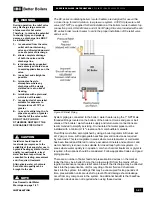

The gas valve is provided with pressure taps to measure gas pressure upstream

(supply pressure) and downstream (manifold pressure) of the gas valve

(see

Figure 31).

Note that manifold pressure varies slightly in accordance with firing

rates with the modulating series boilers / water heaters, but will always be close

to 0" w.c.

1.8

Figure 32: Gas Piping

Figure 31: Gas Valve

WARNING

This boiler / water heater model

can burn either Natural gas or

Propane. Refer to section 3.3

for further instruction.

If a boiler / water heater is to

be converted from one fuel

to another, a conversion kit

must be ordered prior to the

conversion. The conversion

kit must be installed according

to the detailed instructions

supplied with the kit.

Failure to perform the required

fuel conversion correctly can

result in serious injury or death.

NOTE

It is essential to check gas

supply pressure to each boiler /

water heater with a manometer

or other high-quality precision

measuring device. Pressure

should be monitored before

firing the boiler, when the

regulator is in a “lock-up”

condition and during operation,

throughout the boiler’s full

modulation range.

Pay special attention to retrofit

situations where existing

regulators may have an over-

sized orifice and/or worn seats,

causing pressure “creep” and

high lock up pressures.