INSTALLATION AND OPERATION INSTRUCTIONS

1-22

HC SERIES BOILERS

HC 13-50, HC 23-84, HC 29-106, HC 33-124, HC 20-125, HC 33-160

We recommend water flow after burner shutdown to utilize legacy heat – this is

significant due to the mass of the heat exchanger. The boiler pump is under the

control of the boiler to allow pump purge after burner shut-down. Default software

values will run the boiler’s pump for 1 minute after the burner shuts down.

Schematics for several piping layouts are provided herein, and additional

drawings are available at

www.ibcboiler.com

. Installers shall conform the piping

design to one of the provided configurations to simplify the control application,

promote good loads and flow management.

Propylene glycol solution is commonly used in a closed loop where freeze

protection is required. Its density is lower than that of water, resulting in

lower thermal performance at a given flow and pressure. As a rule of thumb,

a 50%:50% solution of propylene glycol and water will require an increased

system circulation rate (gpm up 10%), and system head (up 20%) to provide

performance equivalent to straight water.

The HC series modulating boilers offer exceptional matching of heat generation

to radiation. The low minimum firing is better suited to low thermal loads

presented in a typical multi-zoned radiation system. However, where individual

zones in a heating system have loads under 10,000 Btu/hr, the system will still

benefit through use of a buffer tank to ensure a controlled supply temperature,

and to prevent short cycling. Buffering should be added on the secondary piping

of the relevant load, to avoid bulking up the thermal mass of the primary piping

circuit (and potentially lengthen the duration of the transition from hot to cool

loads).

HC modulating series boilers can be connected directly to a floor of non-

oxygen barrier polybutylene material (PB tubing). The internal boiler piping, and

connections are all non-ferrous with the exception of the corrosion resistant

epoxy coated cast iron pump. For maintenance of warranty on such systems,

we require evidence of a thorough flushing of all loops, plus installation of a dirt

separator or side stream filter. A separator/filter maintenance routine shall be

carried out after the retrofit, with filter clearing after the 1st day, 1st week, month

and annually thereafter.

The installer must insure that all external piping

components and pumps are non-ferrous when connecting the boiler to a

system with non-oxygen barrier tubing.

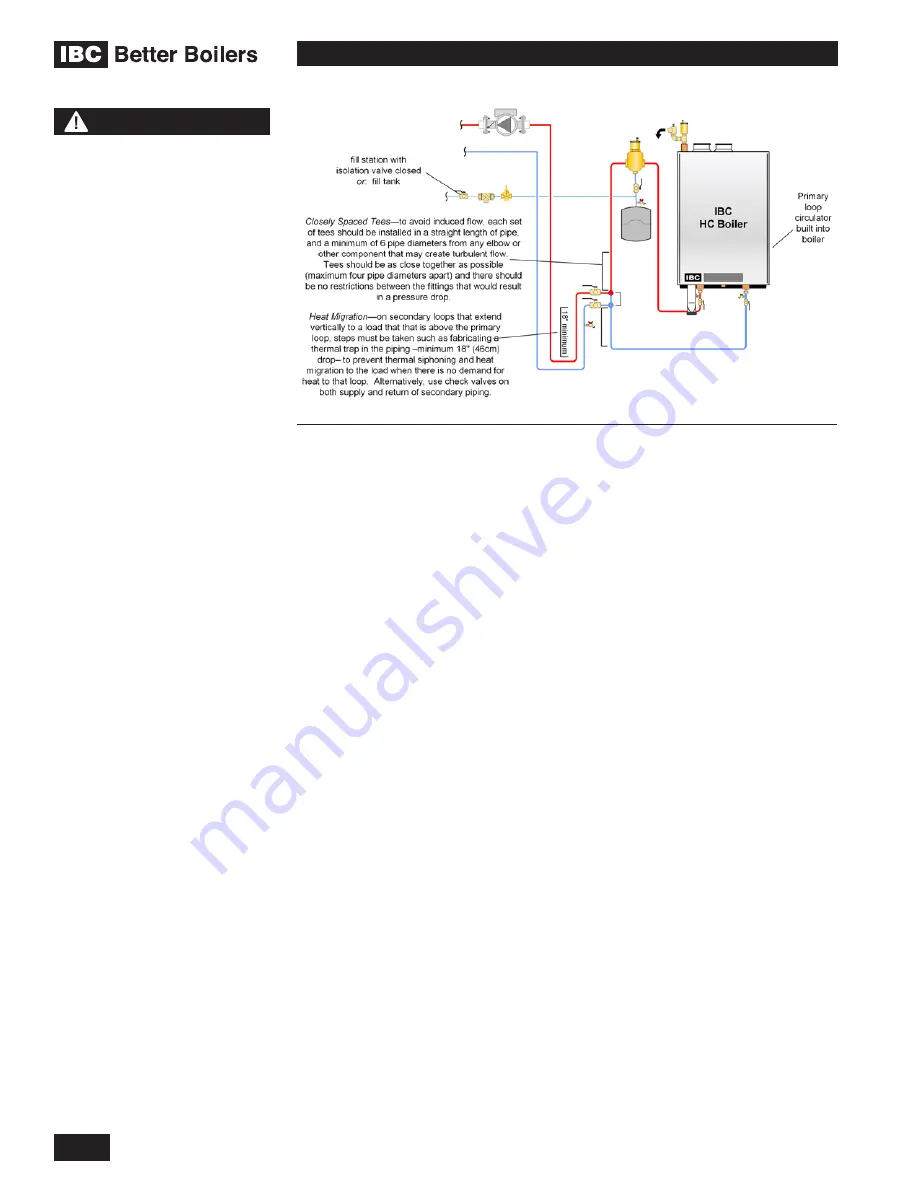

Figure 25: Basic Primary/Secondary piping with closely-spaced tees concept – concept

drawing. This drawing is only a simple schematic guide.

WARNING

Water quality has a significant

impact on the lifetime and

performance of an IBC Boiler

heat exchanger.

Improperly prepared water in

a heating circuit may cause

damage to the heat exchanger

through corrosion or fouling.

Repeated or uncontrolled

water fills will increase the

potential for damage.

High levels of dissolved

solids or minerals may

precipitate out of the fluid

onto the hottest part of the

heat exchanger, impairing

heat transfer and resulting in

overheating and premature

failure. The amount of solids

that may form on the heat

exchanger will depend on

the degree of hardness and

the total water volume in the

system. A high water volume

system with a low hardness

count may cause as much

damage as a system with less

volume and higher hardness,

so it is recommended to treat

water so as to remove all

dissolved solids. Other water

chemistry allowable limits are

as follows:

•

Acidity pH is to be between

6.5 and 8.5

•

Chloride is to be less than

125 mg/l

•

Iron is to be less than 0.3

mg/l

•

Cu less than 0.1 mg/l

•

Conductivity is to be less

than 400μS/cm (at 25°C)

•

Hardness is to be 7 Grains

or less

IMPORTANT: Ensure that

these limits are acceptable

for the other water-side

components in the system.