INSTALLATION AND OPERATION INSTRUCTIONS

1-28

HC SERIES BOILERS

HC 13-50, HC 23-84, HC 29-106, HC 33-124, HC 20-125, HC 33-160

ELECTRICAL CONNECTIONS

All Electrical wiring to the boiler (including grounding) must conform to local

electrical codes and/or National Electrical Code, ANS/NFPA No. 70 – latest

edition, or The Canadian Electrical Code, C22.1 - Part 1.

If an external electrical source is utilized, the boiler, when installed, must be

electrically bonded to ground in accordance with the requirements of the authority

having jurisdiction or, in the absence of such requirements, with the

National

Electrical Code, ANSI/NFPA 70, and/or the Canadian Electrical Code Part I, CSA

C22.1, Electrical Code.

1.8.1 120VAC Line Voltage Hook-up

Line-voltage wiring is done within the field-wiring box.

(Refer to Section

6.2.Wiring Diagram on page 6-4).

Connect the boiler to the grid power using a

separate, fused circuit and on/off switch within sight of the boiler. Use 14-gauge

wire in BX cable or conduit properly anchored to the boiler case for mains supply

and pump circuits.

The boiler is equipped with 3 x 1/2" electrical knock-outs located behind the

power supply terminal strip.

Connect the 120 VAC /15 amp power supply to the AC in connections located

to the right side of the controller. To access the terminal strip, remove the boiler

cover and slide open the controller drawer. Ensure 120 VAC polarity is correct

and that the boiler is properly grounded.

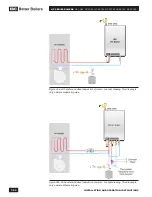

The HC Series boilers include a factory installed and pre-wired pump. The pump

is intended to supply adequate flow for the boiler’s primary heating circuit only.

The system heating pump will need to be switched through a separate relay or

control box.

A second set of contacts is available to connect a DHW pump. This pump will

allow the connection of an indirect fired storage water heater to heating circuit

to take full advantage of the boilers heating capacity. The maximum amperage

rating of the connected pump is 1.0 amps. If the connected pump has a rating

higher than 1.0 amps, an external isolation relay is required to protect the boilers

controller.

A field supplied, external safety device can be connected to the boiler by

connecting the safety device in series with the boilers 120 VAC power supply.

Ensure the external safety device is rated to accept 120 VAC and the total

load connected to the boiler. For an interlock designed for the sole purpose of

protecting the heating circuit of the boiler, the Auxiliary Safety interlocks can be

wired in series with the Call for heat (X4.6 and X4.7). Do not apply power to the

X4 terminal strip. The Auxiliary Safety interlocks must be a Dry Contact.

1.8

NOTE

The IBC control only

recognizes a true dry contact

closure as a call for heat.

Thermostats and other devices

that use a “Triac” output

cannot be used as a call for

heat without the installation of

an intervening relay with dry

contacts to connect to the IBC

terminal strip.

NOTE

The IBC boiler (like any

modern appliance that

contains electronic

equipment), must have a

“clean” power supply, and is

susceptible to power surges

and spikes, lightning strikes

and other forms of severe

electrical “noise”. Power

conditioning equipment

(surge protectors, APC or

UPS devices) may be required

in areas where power quality

is suspect.

WARNING

Do not apply power to any

connection point on the

controllers terminal strips. A

potentially hazardous situation

could occur which must be

avoided to prevent possible

serious injury or death.

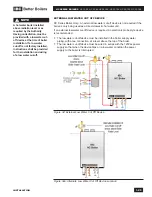

Figure: 32: X4 Terminal Strip for connection of the DHW Aquastat (optional), Thermostat

or end switch’s (mandatory), Outdoor Sensor (optional)

NOTE

Some features of the control

are not available with the HC

Series boilers. The Direct

Domestic Hot Water functions

are not available however the

Indirect Domestic Hot Water

functions are available.