INSTALLATION AND OPERATION INSTRUCTIONS

3-4

HC SERIES BOILERS

HC 13-50, HC 23-84, HC 29-106, HC 33-124, HC 20-125, HC 33-160

FUEL CONVERSION

The HC Series modulating boiler is factory fire-tested to operate with natural gas.

The rating plate will be marked to indicate which fuel the particular boiler has

been set up with. Firing a boiler with a fuel other than what is listed on the rating

plate is prohibited unless the following conversion procedure is completed by a

qualified technician.

Refer to the preceeding section 3.3 - COMMISSIONING. The Low Fire (Zero

Offset) valve adjustment cap on the gas valve has been factory set.

This cap

must not be tampered with. The Zero-offset screw is not to be adjusted in

the field.

Fuel conversion requires hardware adjustments (Orifice Replacement) as well as

measurement and possible tuning of the gas :air mixture. Detailed instructions

including parts and labeling are found in Fuel Conversion kits:

Refer to Table 9

for the correct kit number.

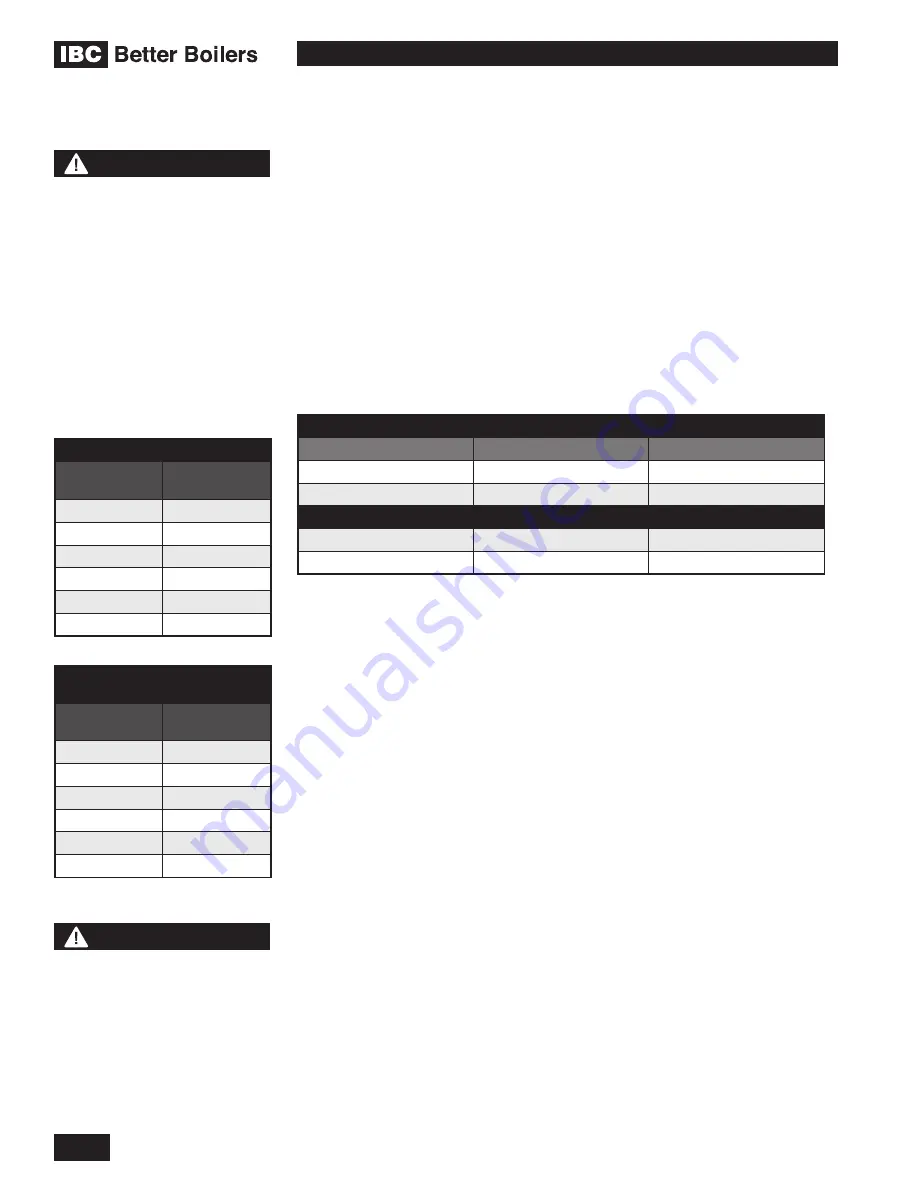

CO

2

VALUE (%) AT HIGH FIRE WITH THE FRONT COVER OPEN

NATURAL GAS

PROPANE

Max. CO

2

value

10.1%

11.5%

Min. CO

2

value

9.1%

9.8%

CO

2

VALUE (%) AT LOW FIRE WITH THE FRONT COVER OPEN

Max. CO

2

value

= value at Max

= value at Max – 0.3%

Min. CO

2

value

9.1%

9.5%

Table 11: CO

2

Values and High and Low Fire

The following procedure must be carried out by a qualified technician.

1.

Ensure the fuel conversion instructions supplied with the fuel conversion kit

are read, understood and followed carefully.

2.

Ensure that the gas supply is turned off at the gas control valve.

3.

Disconnect the gas valve harness plug from the gas valve.

4.

Select the correct Fuel Conversion Kit for your boiler from Table 9.

5.

Disconnect the nut at the gas valve outlet (top of the gas valve) and remove

the orifice and O-ring.

6.

Insert the correct orifice into the O-ring and re-install into the nut at the gas

valve outlet (top of the gas valve) and tighten the nut.

7.

Restore gas supply by opening the gas control valve, and using an approved

leak detection solution, soap test all joints.

8.

Place the conversion labels associated with the new fuel onto the boiler at

the positions indicated on the applicable conversion kit instruction sheet.

9.

Carefully follow the

“Prior to Start-Up” – Section 3.2 and “Commissioning” –

Section 3.3 procedures on the preceeding pages 3-2 and 3-3.

3.5.1 Gaining access to combustion chamber, burner

removal instructions

DIS-ASSEMBLY

1.

Turn off the main power switch to the boiler.

2.

Turn off the gas supply valve to the boiler.

3.4

DANGER

Operating any IBC boiler

using a fuel other than the

fuel listed on its rating plate is

prohibited. If the information

in this section related to

conversion to alternate

fuels is not followed exactly,

a dangerous situation can

result, leading to fire or

explosion, which may cause

property damage, personal

injury, or loss of life.

PROPANE ORIFICE CHART

MODEL

NUMBER

ORIFICE

SIZE

HC 13-50

330

HC 23-84

505

HC 29-106

505

HC 33-124

580

HC 20-125

460

HC 33-160

580

NATURAL GAS ORIFICE

CHART

MODEL

NUMBER

ORIFICE

SIZE

HC 13-50

480

HC 23-84

650

HC 29-106

650

HC 33-124

725

HC 20-125

550

HC 33-160

725

WARNING

When converting a Natural

Gas boiler to Propane, the

Back Flow Valve (located

above the outlet of the fan)

must be removed. Failure to

remove the Back Flow Valve

when using Propane fuel may

result in serious injury or

death.