1-25

INSTALLATION

SL 10-85 G3, SL 14-115 G3, SL 20-160 G3, SL 30-199 G3 MODULATING GAS BOILERS

WARNING

Do not use automotive-type

ethylene or other types of

automotive glycol antifreeze,

or undiluted antifreeze of

any kind. This may result in

severe boiler damage. It is the

responsibility of the Installer to

ensure that glycol solutions are

formulated to inhibit corrosion

in hydronic heating systems

of mixed materials. Improper

mixtures and chemical additives

may cause damage to ferrous

and non-ferrous components

as well as non-metallic, wetted

components, normally found

in hydronic systems. Ethylene

glycol is toxic, and may be

prohibited for use by codes

applicable to your installation

location. For environmental

and toxicity reasons, IBC

recommends only using non-

toxic propylene glycol.

The SL series modulating boilers offer exceptional matching of heat generation to

radiation. The low minimum firing is better suited to low thermal loads presented in a

typical multi-zoned radiation system. However, where individual zones in a heating system

have loads under 10,000 Btu/hr, the system will still benefit through use of a buffer tank to

ensure a controlled supply temperature, and to prevent short cycling. Buffering should be

added on the secondary piping of the relevant load, to avoid bulking up the thermal mass

of the primary piping circuit (and potentially lengthen the duration of the transition from hot

to cool loads).

SL modulating series boilers can be connected directly to a floor of non-oxygen barrier

polybutylene material (PB tubing). For maintenance of warranty on such systems, we

require evidence of a thorough flushing of all loops, plus installation of a dirt separator

or side stream filter. A separator/filter maintenance routine shall be carried out after the

retrofit, with filter clearing after the 1st day, 1st week, month and annually thereafter. Care

is to be taken to avoid use of ferrous fittings and pumps on Non Oxygen Barrier tube

systems.

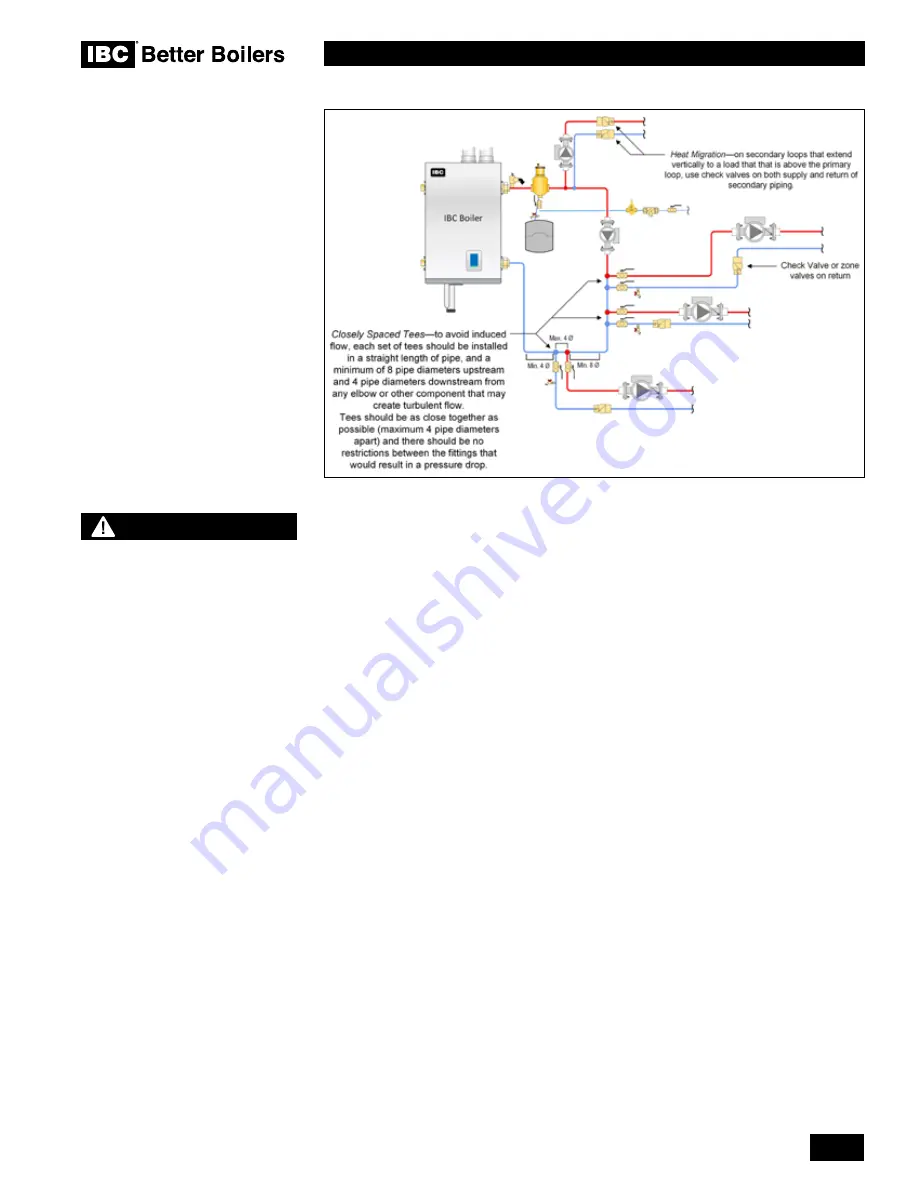

1.6.2 Basic System Piping Arrangements

Primary / Secondary piping - Benefits and installation rules

1. Good circulating water flow through the boiler irrespective of load or radiation system

head

2. Allows flexible ΔT° control in secondary loops

3. Adds to the system’s thermal buffering, to assist in handling small loads and

temperature transition.

A Primary / Secondary piping configuration requires an extra pump, independent from any

secondary load pumps. The SL series modulating boilers’ controller hosts wiring terminals

and integral relays to simplify installation and operation of this preferred layout, offsetting

such costs.

For optimal performance, place pumps on the supply side of secondary loops to facilitate

air evacuation. Use pumps with internal check valves to avoid ghost flows and thermal

siphoning.

Figure 31: Important primary-secondary piping details with closely-spaced tees

Summary of Contents for SL 20-160 G3

Page 75: ...6 3 DIAGRAMS SL 10 85 G3 SL 14 115 G3 SL 20 160 G3 SL 30 199 G3 MODULATING GAS BOILERS...

Page 77: ...6 5 DIAGRAMS SL 10 85 G3 SL 14 115 G3 SL 20 160 G3 SL 30 199 G3 MODULATING GAS BOILERS...

Page 79: ...6 7 DIAGRAMS SL 10 85 G3 SL 14 115 G3 SL 20 160 G3 SL 30 199 G3 MODULATING GAS BOILERS...

Page 85: ...SERVICE RECORD DATE LICENSED CONTRACTOR DESCRIPTION OF WORK DONE...

Page 86: ...NOTES...

Page 87: ...NOTES...