1-9

INSTALLATION

SL 35-199, SL 45-260 MODULATING GAS BOILERS

•

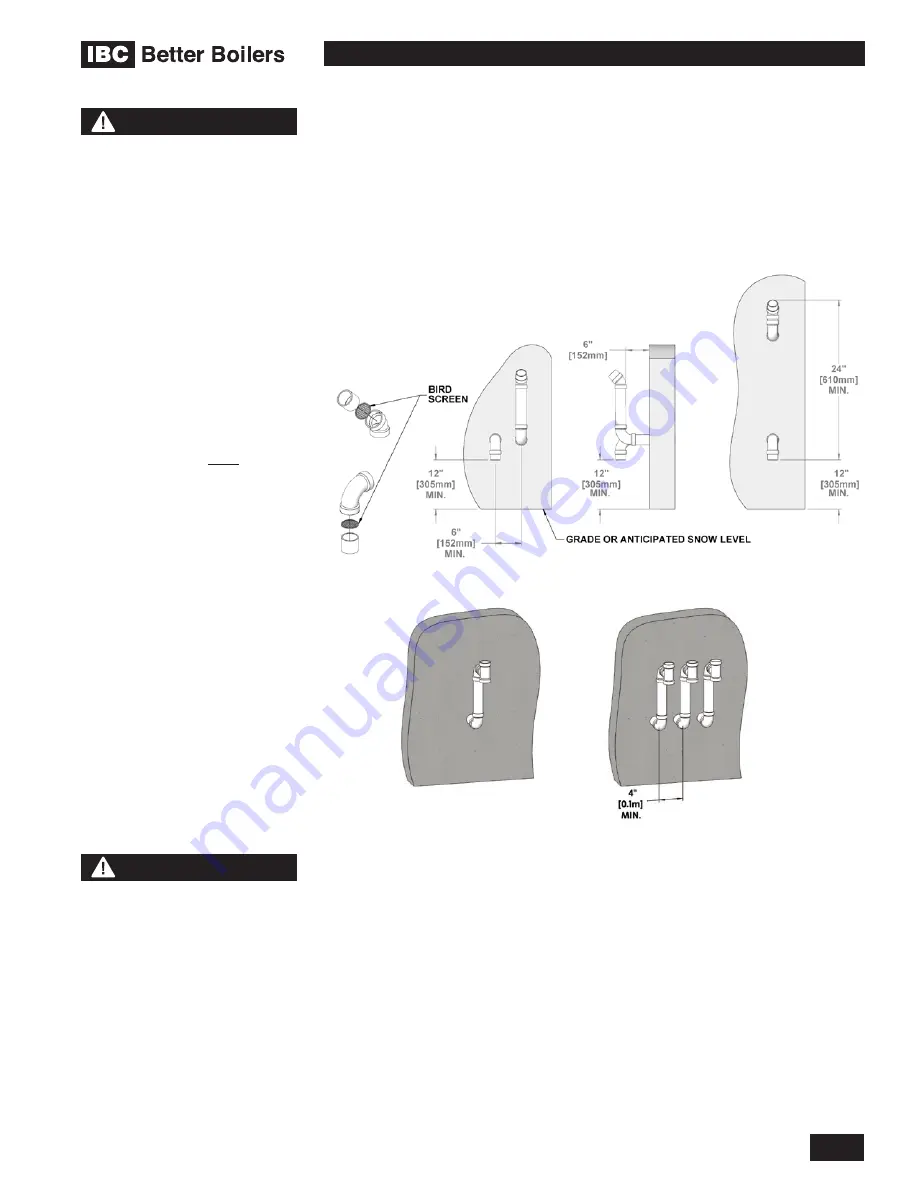

The exhaust outlet is to be placed so as to reach 24” minimum above the

down-turned intake - to avoid intake re-ingestion of exhaust gases.

•

The elevation of both pipes can be raised in “periscope style” after passing

through the wall, then configured as in

Figure 5

, to gain required clearance.

•

Use a 45° elbow on the exhaust termination to launch the plume up and off

the sidewall, for protection of wall.

•

Bird screen of 1/4” stainless steel or plastic mesh eg. (IPEX System 636 drain

grate for CPVC systems) is useful to guard against foreign objects.

Sidewall indoor combustion air applications shall be vented as follows:

•

The exhaust outlet is to be placed 12” above grade or anticipated snow level

(18” min in Canada; check local code requirements).

•

The vent shall be terminated with a tee fitting as illustrated (s

ee Figure 6).

•

Bird screen, as above, should be installed in both open ends of the tee.

For side venting of multiple boiler sets, group all intake terminals together with

4” (minimum) lateral spacing, and similarly group the exhaust pipes. Place the

2 groups on the same plane of the building (e.g. north facing wall). Place the 2

groups of pipes at least 3’ apart (the closest intake and exhaust pipes shall be

36” - or more – apart. Use same 24” (minimum) vertical separation. Alternately,

as long as the boilers are identical models - intake and exhaust terminals can

maintain a minimum of 12” of separation horizontally from any exhaust or inlet

termination of an adjacent boiler. For alternate group terminations, contact the

IBC Factory for written guidance.

WARNING

It is extremely important

to maintain at least the

minimum separation of

exhaust vent termination

from boiler intake air as

illustrated in figures 4, 5 and

9. Failure to do so can result

in a dangerous situation

where exhaust gasses are

re-ingested with combustion

air. Damage to the boiler

can result from a failure to

maintain these separations.

Third party vent termination

kits and concentric wall

penetration kits that do not

maintain these minimum

separations shall NOT be

used. Improper installation

will void the warranty. Do not

use proprietary Innoflue or

PolyPro sidewall terminals

without specific written

approval from IBC.

WARNING

In areas of high snowfall,

Users must be advised to

check side wall vent and

air intake terminations on

a regular basis to ensure

blockage does not occur.

Figure 5: Sidewall vent termination - piping configuration

Figure 6: Sidewall vent termination - indoor combustion air applications

Summary of Contents for SL 35-199

Page 71: ...SERVICE RECORD DATE LICENSED CONTRACTOR DESCRIPTION OF WORK DONE...

Page 72: ...NOTES...

Page 73: ...NOTES...