1-17

INSTALLATION

SL 35-199, SL 45-260 MODULATING GAS BOILERS

WATER PIPING

1.6.1 General Piping Issues

The SL 35-199 and SL 45-260 boilers were designed to be easy to install in

almost any application.

Primary/secondary piping, or the use of a hydraulic separator is recommended

for maximum flexibility in multi-load applications, but piping loads in parallel

is also encouraged in systems that only have two loads, or when loads are

operating simultaneously. The extremely low pressure drop through the SL Series

heat exchanger allows many options not available in other designs. In short –

IBC has built a boiler that will allow you to pipe the system the way you prefer,

rather than try and dictate your piping practices from boiler to radiator.

There are some important details to consider however, and this section of the

Installation and Operating Manual will walk you through them so you can enjoy a

trouble-free installation.

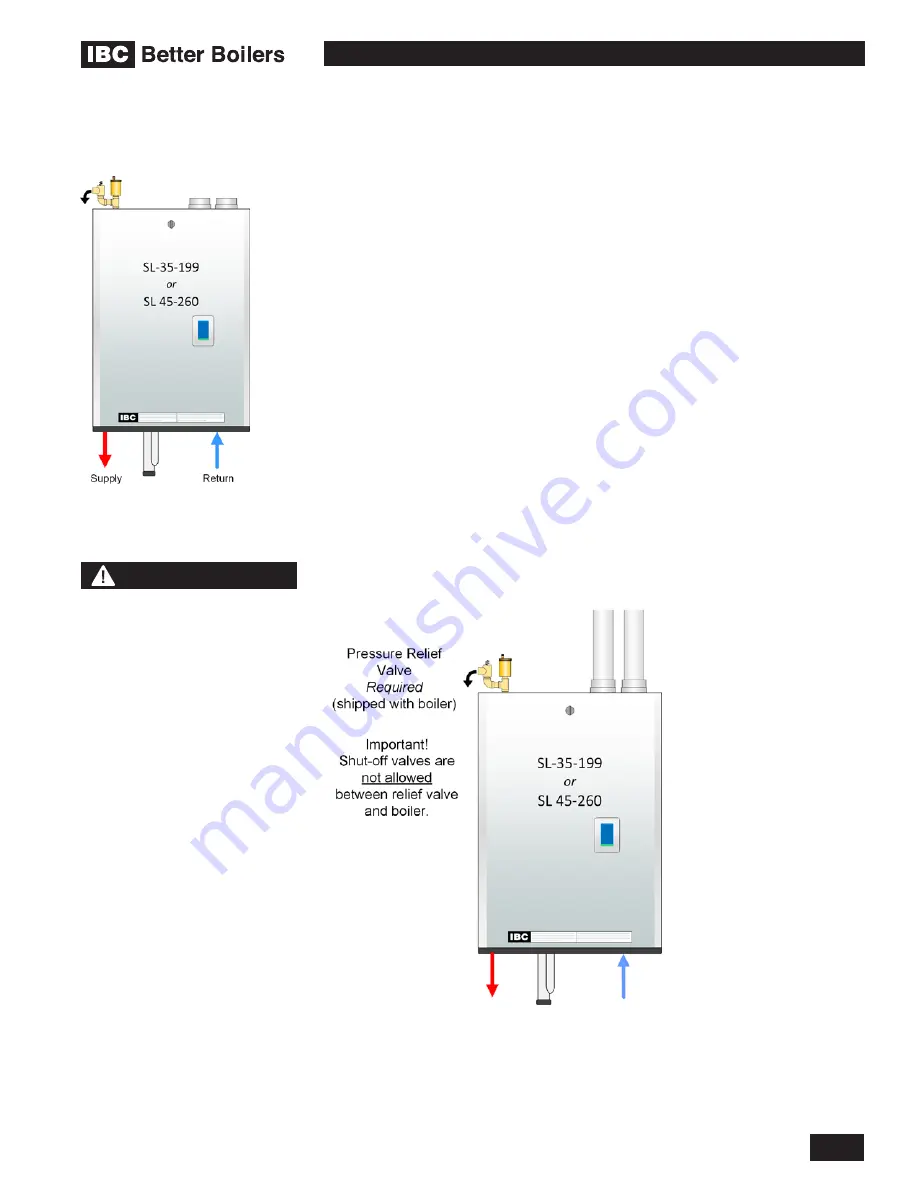

The SL modulating series boilers are designed for use within a closed loop,

forced circulation, low pressure system. A 30 psi pressure relief valve (3/4” NPT)

is supplied for field installation at one of the locations shown in the following

illustrations. Relief valve discharge piping must terminate between 6” (15cm) and

12” (30cm) above the floor or per local Code.

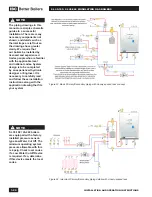

Figure 19: Overview of piping options

1.6

Figure 20: Relief piping with single side piping connections

WARNING

During operation, the relief

valve may discharge large

amounts of steam and/or hot

water. Therefore, to reduce

the potential for bodily

injury and property damage,

a discharge line MUST be

installed that it:

1. is connected from the valve outlet

with no intervening valve and

directed downward to a safe point of

discharge.

2. allows complete drainage of both the

valve and the discharge line.

3. is independently supported and

securely anchored so as to avoid

applied stress on the valve.

4. is as short and straight as possible

5. terminates freely to atmosphere

where any discharge will be clearly

visible and is at no risk of freezing.

6. terminates with a plain end which is

not threaded.

7. is constructed of a material suitable

for exposure to temperatures of

375°F or greater.

8. is, over its entire length, of a pipe size

equal to or greater than that of the

valve outlet.

DO NOT CAP, PLUG OR OTHERWISE

OBSTRUCT THE DISCHARGE PIPE

OUTLET!

Summary of Contents for SL 35-199

Page 71: ...SERVICE RECORD DATE LICENSED CONTRACTOR DESCRIPTION OF WORK DONE...

Page 72: ...NOTES...

Page 73: ...NOTES...