3-3

STARTUP AND COMMISSIONING

SL 35-199, SL 45-260 MODULATING GAS BOILERS

de-ration. The boiler will automatically de-rate at altitudes above 4,500 feet.

Refer to the IBC Altitude tables for further information.

To verify proper operation of the gas valve in the field, the following procedure

can be carried out by a qualified technician.

1.

Turn OFF the gas supply to the boiler. With a small (1/8" or 3 mm) flat

screwdriver, open the inlet gas supply pressure test port by turning its

center-screw 1 full turn counterclockwise. Attach a manometer to the

pressure test port and turn on gas to appliance. Static manometer reading

should be ideally 7” w.c., for Natural Gas and 11” w.c. for Propane. Minimum

and maximum static pressure should be between 5” and 14” w.c. Monitor

pressure throughout the commissioning procedure. Pressure may droop up

to 1” to 2” w.c. at high fire but under no circumstances should it drop below 4”

w.c. at the gas valve inlet test port.

2.

Allow the boiler to ignite. Run against a large load, to maintain high fire.

3.

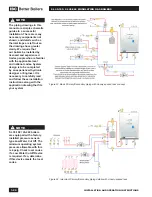

With a combustion analyzer probe in the flue gas test port, turn the Gas:Air

Ratio Adjustment screw

(see Figure 31a for the SL 35-199 Gas Valve and

Figure 31b for the SL 45-260 Gas Valve)

to achieve results listed in Table

7 below. Check and adjust if necessary the high fire CO

2

levels first before

checking and adjusting the low fire settings. High Fire = to increase the

CO

2

turn the adjustment screw Counter Clockwise (

see Table 7 below for

corresponding CO

2

values - set for CO

2

target at high fire

).

4.

Confirm the minimum fire level settings. Re-define the load as “Manual

Control”. Use Heat Output in “Configure Load x” to control the output as

needed. Reading should be within Low fire range. Re-test at high fire.

5.

Turn boiler off by removing the call for heat (use the Installer Set Up

screen to turn load to off if no other ready means available). Turn off gas

then remove the manometer connections, and turn the centre-screw in the

manifold pressure test port clockwise until fully closed. Ensure fully closed,

but not over-tightened. Restore gas and soap test for leaks.

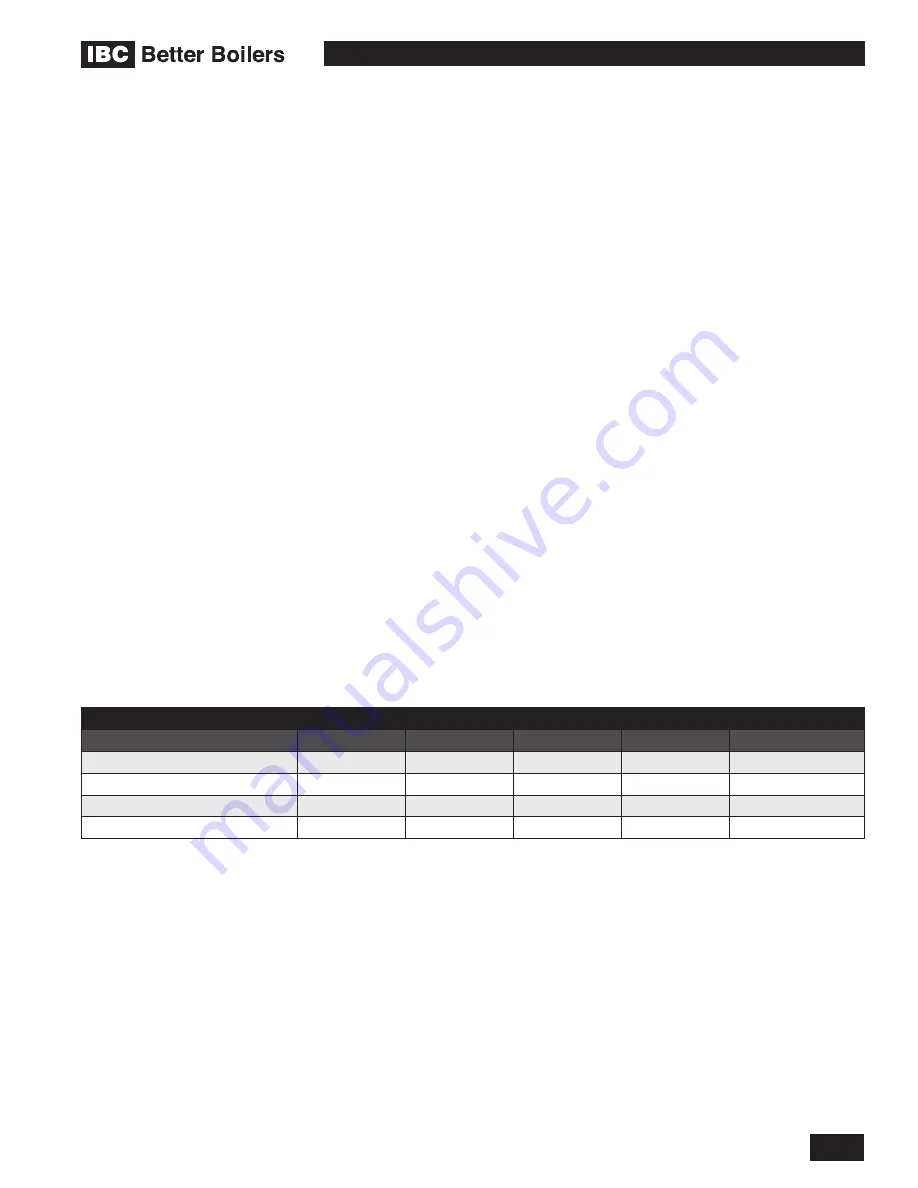

MODEL

HIGH FIRE

LOW FIRE

CO MAX PPM

RANGE

TARGET

RANGE

TARGET

SL 35-199 (Natural Gas) CO

2

9.1 -9.7

9.5

8.4 – 9.0

8.7

150

SL 35-199 (Propane) CO

2

10.5 – 11.1

10.8

9.4 – 10.2

9.8

180

SL 45-260 (Natural Gas) CO

2

9.1 – 9.7

9.5

8.4 – 9.0

8.7

120

SL 45-260 (Propane) CO

2

10.5 – 11.1

10.8

9.4 – 10.2

9.8

150

Table 7: Combustion test target ranges - CO

2

/ Maximum CO

Summary of Contents for SL 35-199

Page 71: ...SERVICE RECORD DATE LICENSED CONTRACTOR DESCRIPTION OF WORK DONE...

Page 72: ...NOTES...

Page 73: ...NOTES...