5-3

TROUBLESHOOTING

SL 35-199, SL 45-260 MODULATING GAS BOILERS

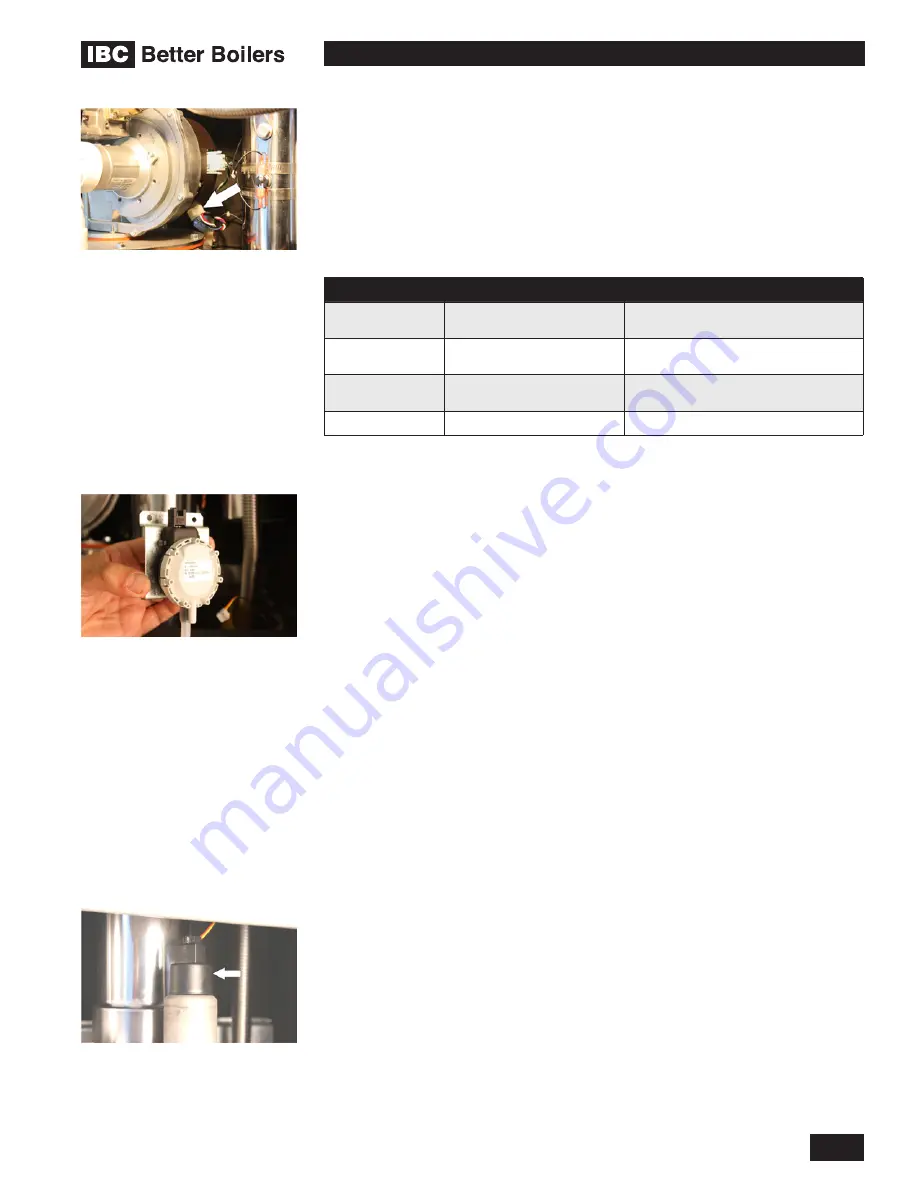

5.2.2 Fan/Blower

Operating power is provided by means of a separate 120 VAC connector at the

bottom of the fan (white/black/green). Control of the fan is provided via a four

lead connector at the top of the fan. This connector feeds a PWM control signal

(black wire) from the controller and provides a tachometer signal (white wire)

back from the fan. Unplugging the control connector will cause the fan to go to

high speed and trigger a “Blocked Vent Error” within 6 seconds if the boiler is

operating.

LEAD COLOR

FUNCTION

TROUBLESHOOTING

Red

35 VDC Positive power

terminal

Fan will only operate at max. speed if

disconnected.

Blue

35 VDC Negative power

terminal

Fan will only operate at max. speed if

disconnected.

Black

Signal from controller

Fan will only operate at max. speed if

disconnected.

White

Fan tach.

2 pulses/rev (freq x 30=rpm)

Table 10: Fan Operation

5.2.3 Differential Air Pressure Sensor

Do not blow into the ports of the sensor, this is not a switch and “does not

click when closed”. Excessive pressure will damage the sensor thus requiring

replacement. The sensor values are located in the advanced diagnostics section

of the controller. In general, the Fan Pressure and the Required Pressure

should be very close to each other while the boiler is in operation. If the required

pressure is higher than the actual pressure there are several possible causes.

•

Exhaust and/or Air Intake piping installed longer that allowed

•

Improper grading of the Exhaust and/or Air Intake piping allowing condensate

to be trapped in the piping

•

Re-Ingestion of flue gasses has caused the Venturi and/or Fan Impeller to

erode, becoming ineffective.

•

Air Pressure Sensor tubing not correctly attached.

5.2.4 Water Pressure Sensor

The water pressure sensor ensures there is adequate pressure in the heating

system for safe operation. The pressure is displayed in PSI as the default. If the

system pressure should drop below 8PSI the firing rate of the boiler is reduced.

If the pressure drops to 4PSI or lower, the boiler will not fire.

Check operation of the sensor by isolating the boiler from its system piping,

closing the system fill valve then cracking the pressure relief valve; the pressure

displayed should reflect declining pressure. If it remains “fixed”, drain boiler and

replace sensor, or dislodge any blocking debris from sensor inlet channel and

reinsert.

Control wire plug

Air pressure sensor. Do not blow

into sensor ports.

Water pressure sensor

Summary of Contents for SL 35-199

Page 71: ...SERVICE RECORD DATE LICENSED CONTRACTOR DESCRIPTION OF WORK DONE...

Page 72: ...NOTES...

Page 73: ...NOTES...