9

USER’S INFORMATION MANUAL

SL SERIES BOILERS

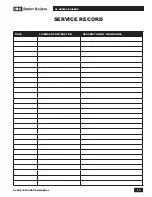

MAINTENANCE

Daily Maintenance

•

Check the surrounding area – inspect for water leaks in the general area

around the boiler and boiler piping

•

Check the system pressure. The heating system pressure should not exceed

25psi (SL 80-399 - 75psi) and not drop below 10psi in most applications. If the

pressure is outside this normal range or if the water pressure fluctuates more

than 2-3psi, contact your qualified service technician for service.

•

Check the area around the boiler and the air intake opening for obstructions

and chemical contaminates.

Monthly Maintenance

•

Check all the Daily Maintenance items.

•

Check the pressure relief valve and discharge piping for signs of leakage

or moisture. If water or moisture is found, contact your qualified service

technician as soon as possible for service.

•

Check the condensate trap and outlet pipe. The condensate trap shall be full

of water. The outlet hose may be connected to a condensate neutralizer, if so,

check the pH of the water coming out of the neutralizer is above 6.0pH. If the

pH is below 6.0 then the neutralizer will need to be re-charged or replaced.

Contact your qualified service technician for service.

•

Inspect the flue gas exhaust and air intake connections. All connections

should be tight and leak free.

•

Inspect flue gas exhaust piping, combustion air piping and terminations.

Annual Maintenance

The boiler must be inspected by your qualified service technician for the following:

•

Check the Error Logs for any issues.

•

Inspect the flue gas exhaust and air intake connections. All connections

should be tight and leak free.

•

Inspect flue gas exhaust piping, combustion air piping and terminations.

•

Inspect the boilers interior and vacuum if required.

•

Check for water, gas and condensate leaks in the boiler and around the boiler.

•

Check the condensate trap and clean if required. Re-fill the trap and re-install

the trap hook.

•

Check the water pressure, expansion tank and pumps.

•

Check the electrical connections.

•

Check the ignition electrode and remove oxidation from the electrode.

Replace if necessary.

•

Check the gas valve and ignition cable.

•

Check the controller settings.

•

Check the burners flame. Should be a quick and quiet ignition across the full

burner.

•

If required, clean the heat exchanger and the burner.

WARNING

Annual Maintenance must only

be done by a qualified service

technician.

CAUTION

The heat exchanger has a small

amount of combustion chamber

insulation (refractory), which

contains ceramic fibers. When

exposed to extremely high

temperatures, the ceramic fibers,

which contain crystalline silica,

can be converted into cristobalite

- which is classified as a possible

human carcinogen.

Care should be taken to avoid

disturbing or damaging the

refractory. If damage occurs,

contact the factory for directions.

Avoid breathing and contact with

skin and eyes and follow these

precautions:

1.

For conditions of frequent

use or heavy exposure,

respirator protection is

required. Refer to the “NIOSH

Guide to the Selection and

Use of Particulate Respirators

Certified under 42 CFR

84” for selection and use

of respirators certified by

NIOSH. For the most current

information, NIOSH can be

contacted at 1-800-356-4676

or on the web at www.cdc.

gov/niosh.

2.

Wear long sleeved, loose

fitting clothing, gloves and

eyes protection.

3.

Assure adequate ventilation.

4.

Wash with soap and water

after contact.

5.

Wash potentially

contaminated clothes

separately from other

laundry and rinse washing

machine thoroughly.

6.

Discard used insulation in an

air tight plastic bag.

NIOSH stated first aid:

•

Eye contact - Irrigate and

wash immediately.

•

Breathing - Provide fresh air.