Continued from previous page

Probable fault cause

Overcurrent

MicroMax180 limits the current at 2.4 A and trips then after 4-5 s.

- The motor is too small in relation to rotor diameter

- Rotor rotation sluggish

- Damaged motor, e.g. bearing fault

Measure current.

NOTE! Precise voltages and amperages can only be obtained with a

moving-iron instrument.

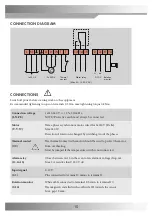

SETTINGS VIA POTENTIOMETER

Boost

Torque boost at low rpm.

May be increased if necessary, but motor temperature will increase.

Factory setting at 12 o’clock.

Threshold value

The control unit will start when the input signal exceeds the threshold

value, adjustable between 0-2 V.

Factory setting, min.

Max rpm

Potentiometer for adjusting maximum rpm.

Adjust between 40-100 Hz.

Factory setting, min.

RESET

Reset

Reset button for resetting the control unit.

The control unit also resets in the event of voltage drop-out.

In both cases, all alarms reset.

Automatic restart takes place after a voltage drop-out.

------------------------------------------------------------------------------------------------------

9

Summary of Contents for MicroMax180

Page 2: ......

Page 15: ...PERSONAL NOTES 13 ...