pressure gauge and turn off the vacuum

pump.

Maintain pressure for 20 minutes and

make sure there is no leak.

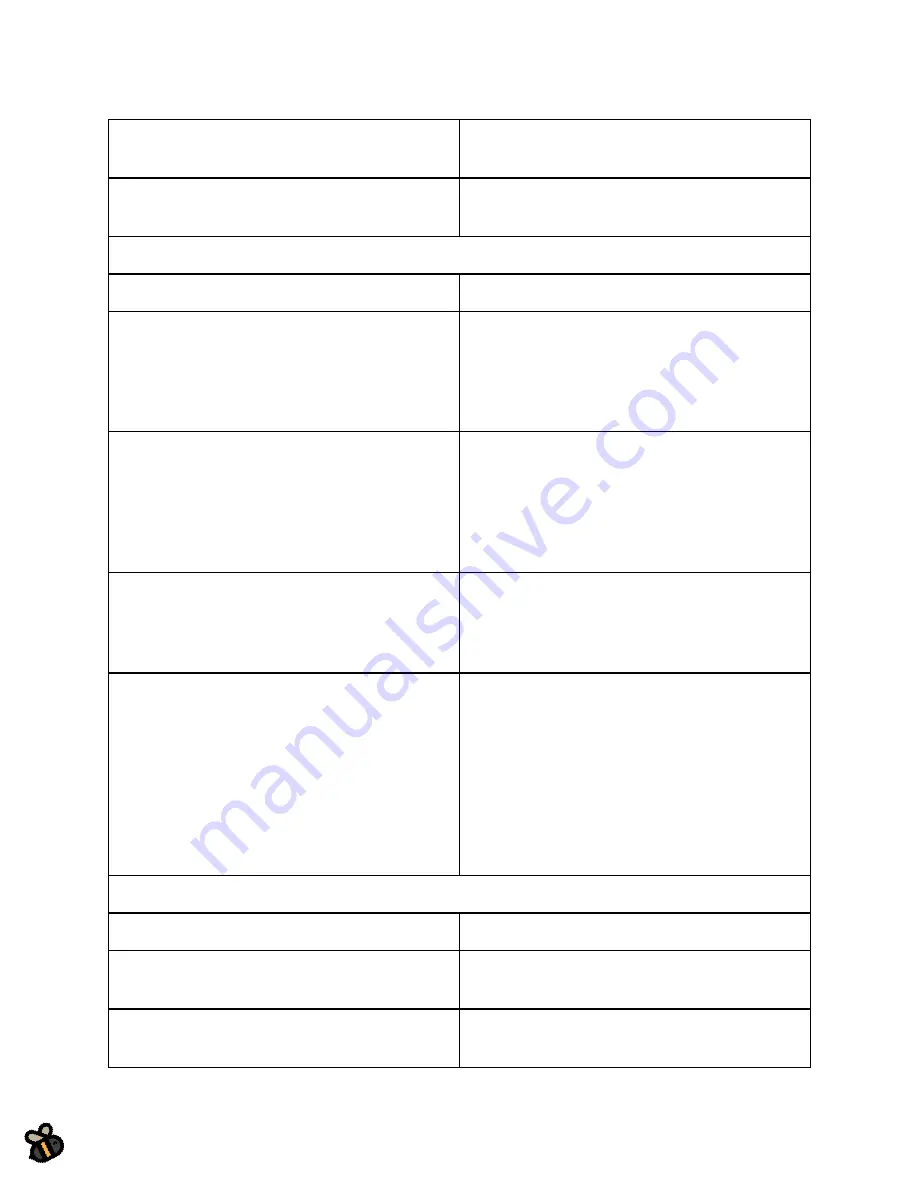

INJECTING REFRIGERANT

STEP

PRECAUTION

Remove the vacuum pump from the

charging meter. Connect the refrigerant

cylinder to the charging meter with the

connection pipe as short as possible.

Unscrew refrigerant cylinder and put it

upside down on the electronic scale.

ATTENTION: The charging volume is

very small for the R290 refrigeration

system, so it’s necessary to precisely

control the charging volume within 2g.

The precision of the electronic scale shall

be 0.5g.

Prepare the connection pipe, pressure

gauge and accessories; empty the

charging pipe; and set the electronic

scale to zero.

The hose connecting the cylinder and

charging meter shall be tension-free to

minimize error of charging volume.

Slowly open the low pressure valve of the

pressure gauge. When the charging

volume reaches the rated volume

indicated on the nameplate, immediately

close the low pressure valve, and then

close the R290 refrigerant cylinder to stop

the charging.

NOTE: Keep charging pressure below

3Bar all the time to prevent fast charging.

Fast charging will lead to a charging error.

SEALING AND COMMISSIONING

STEP

PRECAUTION

Use a leak tester to check the machine

for any leaks.

After confirming there is no leak, use the

sealing pliers to clamp flat the process

10