18

Suspected malfunctions are often due to causes that the users can

fix themselves, therefore check the product using this section. In

most cases the problem can be solved quickly.

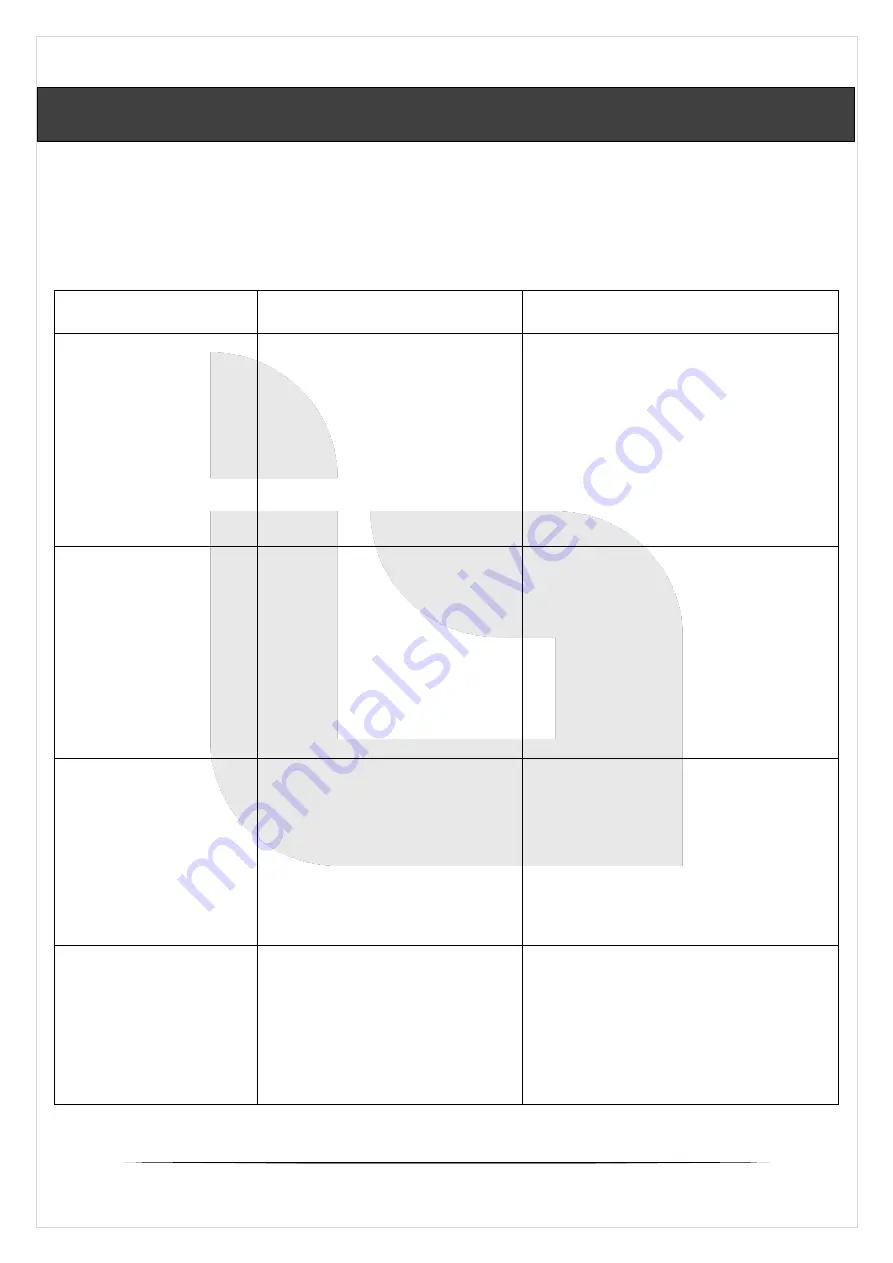

Problem

Possible Cause

Solution

1. Motor not

working.

1.1 Wire in the main

plug or in the

socket is loose.

1.2 Switch is faulty.

1.1 Have the socket and

plug checked by a

qualified technician.

1.2 Have the switch

checked/replaced by

a qualified technician.

2.

Excessive

sparkling

during

operation

2.1 Ring fire caused

by short circuit in

rotor winding.

2.2 Carbon brushes

are worn out or

jammed.

2.1 Check or replace

rotor by a technician.

2.2 Check or replace

carbon brushes.

3.Unsatisfactory

result

3.1

Improper

installation of

the guard.

3.2 Damaged/Worn

out sanding disc.

3.1

Reinstall the guard.

3.2 Replace the sanding

disc.

4. Machine

overheating

4.1 Overload run.

4.2 Odd substances

inside the motor.

4.1 Conduct the

operation correctly.

(Use less pressure)

4.2 Have the odd

substances removed.

TROUBLESHOOTING

IBL DS80-70|90

Summary of Contents for DS 80-70

Page 1: ...DRYWALL SANDER DS80 70 90 ...

Page 2: ...1 ...