Powering on the system

After you install all hardware components, you must power on the system and check its status. Each control enclosure has two power

supply units (PSUs). To provide redundancy in a power failure, connect the power cords to separate power circuits.

Attention:

Do not power on the system with any open bays or drive slots. Open bays or drive slots disrupt the internal air flow,

causing the drives to receive insufficient cooling.

• Every unused drive bay must be occupied by a filler panel.

• Filler panels must be installed in all empty host interface adapter slots.

1.

Ensure that the circuit breakers or switches of the power sources are turned on.

2.

Use the supplied power cords to connect both PSUs of the control enclosure and each expansion enclosure to their power sources.

3.

Check the status LED indicators on the back of each node in the control enclosure and on each expansion enclosure.

The enclosure is ready with no critical errors when the

Fault

LED is off, the

Power

LED is on, and the

Status

LED is blinking (for the

control enclosure) or solid (for expansion enclosures).

Setting up the system or adding the control enclosure to an existing system

The system can contain 1-4 control enclosures. If you are adding this control enclosure to an existing system, go to

enclosure to an existing system

on page 10. Otherwise, continue to

on page 9.

Setting up the system

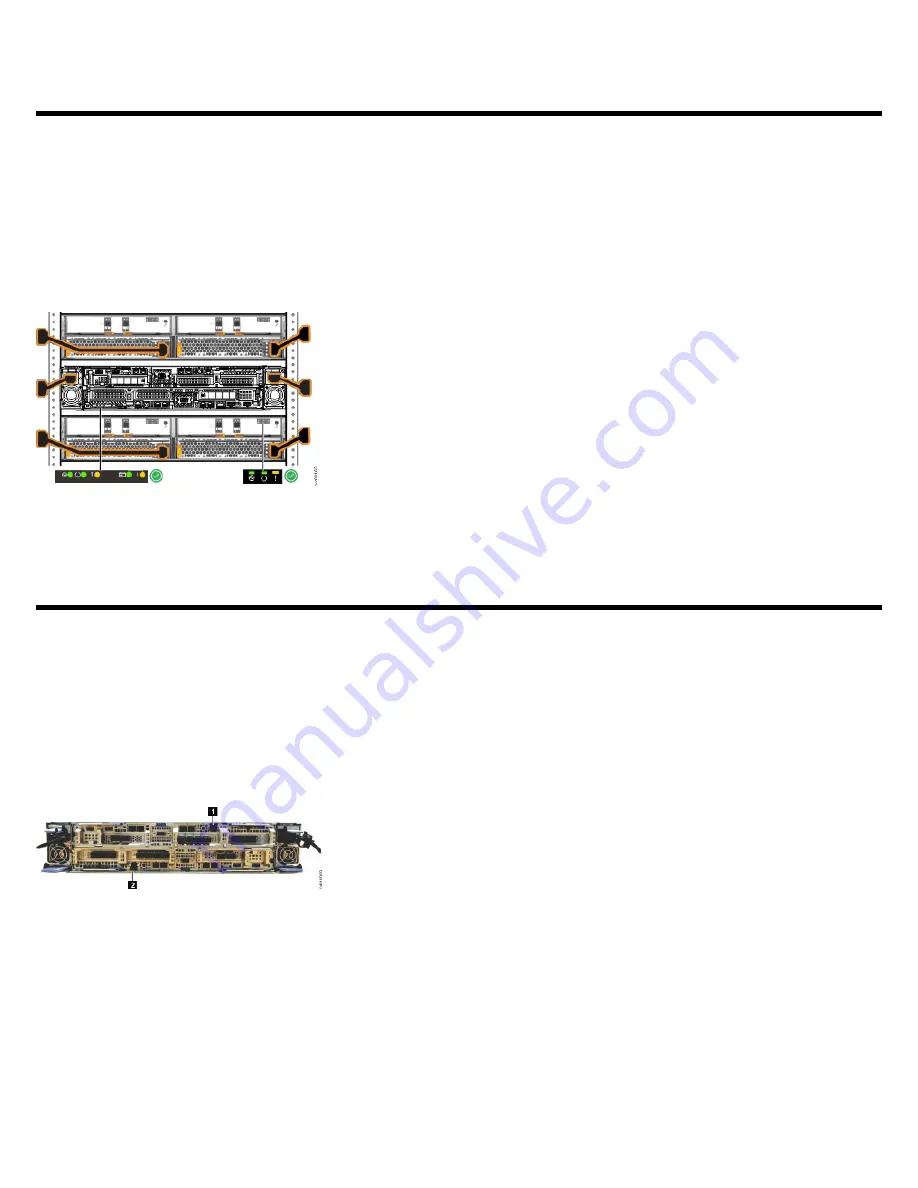

Each node canister in the control enclosure has a 1 Gbps Ethernet technician port. Before you initiate a new system, you must connect an

Ethernet cable to the technician port on the control enclosure.

1.

Locate the technician ports on the control enclosure. Because node canister 1 is inverted, the plug of the Ethernet cable also needs to be

inverted to connect to the technician port.

2.

Connect an Ethernet cable to a technician port. The cable must be long enough to connect easily to a notebook computer.

3.

Open a new web browser page. The web browser might display a warning about a potential security risk. It is safe to accept the risk and

continue.

4.

If the node canisters communicate with each other using RDMA over Ethernet, browse to address

http://service

or press the

wrench icon on the initialization page to access the Service Assistant Tool. The initial superuser password is

passw0rd

. Use the Change

node IP tab of the Service Assistant to configure the node IP settings for the node. Repeat this step for each node canister in the system.