Chapter 3. Install the appliance into a rack

Many racks are on the market, which means that the assembly procedure might differ slightly. This rail

fits a rack between 26.5" and 34.5" deep.

Prepare for installation

Assemble tools

A #2 Phillips screwdriver and a cage nut tool are needed to install and secure the rails to the appliance.

Wear a set of leather work gloves when racking the appliance. They help to get a grip on the appliance

and avoid injury from any metal edges.

CAUTION:

Do not use of any sort of hammer to secure the rails on the appliance. A hammer might damage the

drives within the chassis and possibly void the warranty.

Choose a setup location

Decide on a suitable location for the rack unit that holds your appliance.

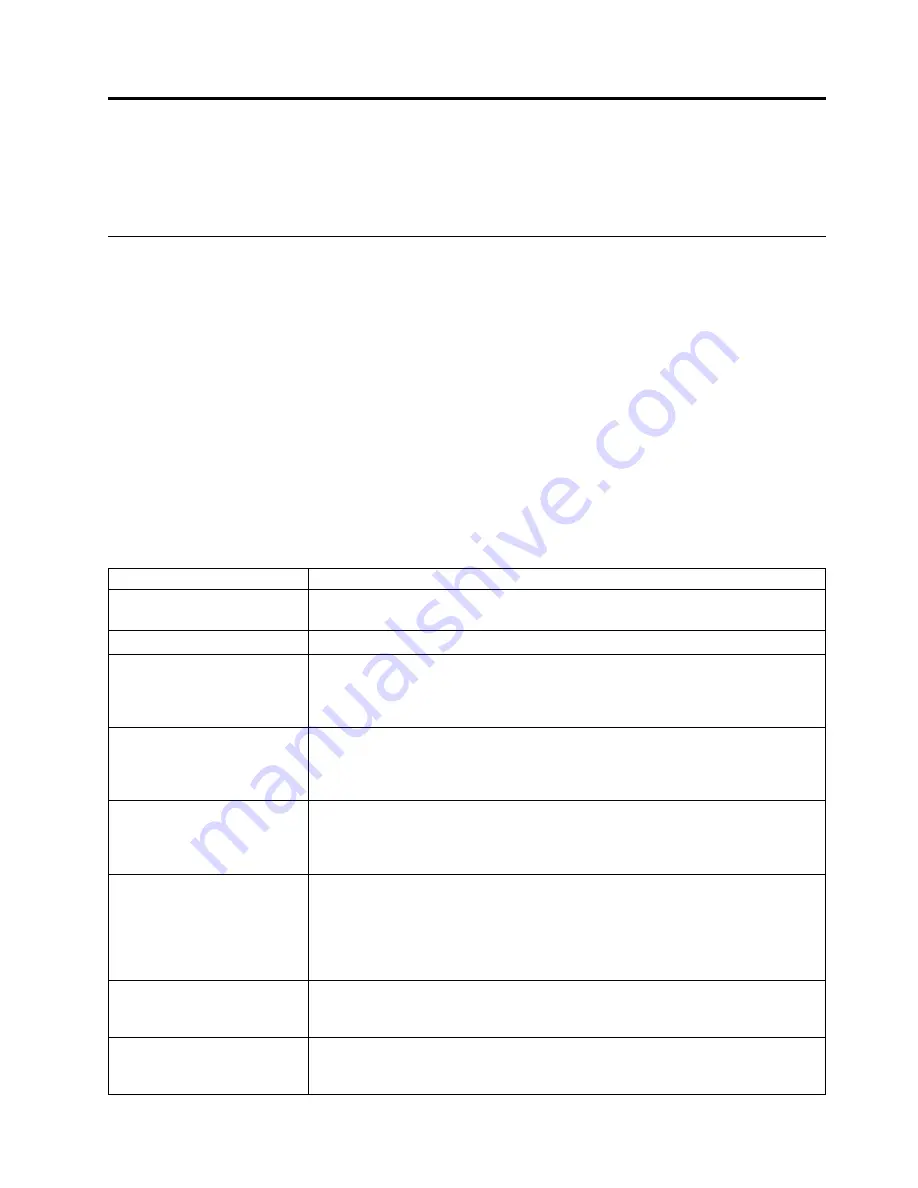

Table 5. Appliance location considerations

Factor

Comments

Restricted access location

Install this appliance in a physically secure, limited access location only, such as a

service closet or data center.

Clean environment

Situate the appliance in a clean, well-ventilated, dust-free area.

Ambient operating temperature If installed in a closed or multi-unit rack assembly, the ambient operating

temperature of the rack environment might be greater than the ambient

temperature of the room. Install the equipment in an environment compatible with

the maximum rated ambient temperature (TMRA) for the appliance.

Sufficient airflow

Mount the equipment into a rack so that the amount of airflow that is needed for

safe operation is not compromised. Leave enough clearance in front of the rack to

open the front door completely (36 inches). Leave about 36 inches of clearance

behind the rack for sufficient airflow and ease in servicing.

Mechanical loading

Mount the equipment into a rack so that a hazardous condition does not arise due

to uneven mechanical loading. Install heavier items into the bottom of the

equipment rack to keep the rack stable. Mount equipment in a rack evenly to

prevent a later hazard.

Circuit overloading

Give consideration to the connection of the equipment to the power supply

circuitry and the effect that any possible overloading of circuits might have on

overcurrent protection and power supply wiring. Appropriate consideration of

equipment nameplate ratings should be used when addressing this concern.

Note:

The maximum current draw is printed on a label on the appliance power

supplies. The system can draw more than 15 Amps at startup (inrush current).

Reliable ground

A reliable ground must be maintained always. To ensure grounding, the rack itself

should be grounded. Give particular attention to power supply connections other

than the direct connections to the branch circuit, such as the use of power strips.

Power supply

Use a regulating uninterruptible power supply (UPS) to protect the appliance from

power surges and voltage spikes, and to keep your system operating in a power

failure.

© Copyright IBM Corp. 2016, .

5

Summary of Contents for 3401-A00

Page 4: ...iv IBM Cloud Object Storage System Accesser 3105 Appliance Manual 3409 A00 3401 A00 3403 A00 ...

Page 6: ...vi IBM Cloud Object Storage System Accesser 3105 Appliance Manual 3409 A00 3401 A00 3403 A00 ...

Page 10: ...x IBM Cloud Object Storage System Accesser 3105 Appliance Manual 3409 A00 3401 A00 3403 A00 ...

Page 16: ...xvi IBM Cloud Object Storage System Accesser 3105 Appliance Manual 3409 A00 3401 A00 3403 A00 ...

Page 30: ...12 IBM Cloud Object Storage System Accesser 3105 Appliance Manual 3409 A00 3401 A00 3403 A00 ...

Page 42: ...24 IBM Cloud Object Storage System Accesser 3105 Appliance Manual 3409 A00 3401 A00 3403 A00 ...

Page 43: ......

Page 44: ...IBM Printed in USA ...