1. Configuration dependent, base rack weight plus the weight of the drawers mounted in the rack. The rack can

support up to a maximum weight of 35 lbs/EIA (Unit).

2. The total rack power should be derived from the sum of the power used by the drawers in the rack.

3. The Power Distribution Panel (PDP) on the DC powered rack can hold up to eighteen (nine per power source) 48

volt 20 to 50 amp circuit breakers (configuration dependent). Each power source supports up to 8.4 kVA.

4. Each ac Power Distribution Bus (PDB) can supply 4.8 kVA. A rack can have up to four PDBs as required by the

drawers mounted in the rack.

5. All rack installations require careful site and facilities planning designed to both address the cumulative drawer

heat output and provide the airflow volumes rates necessary to comply with drawer temperature requirements.

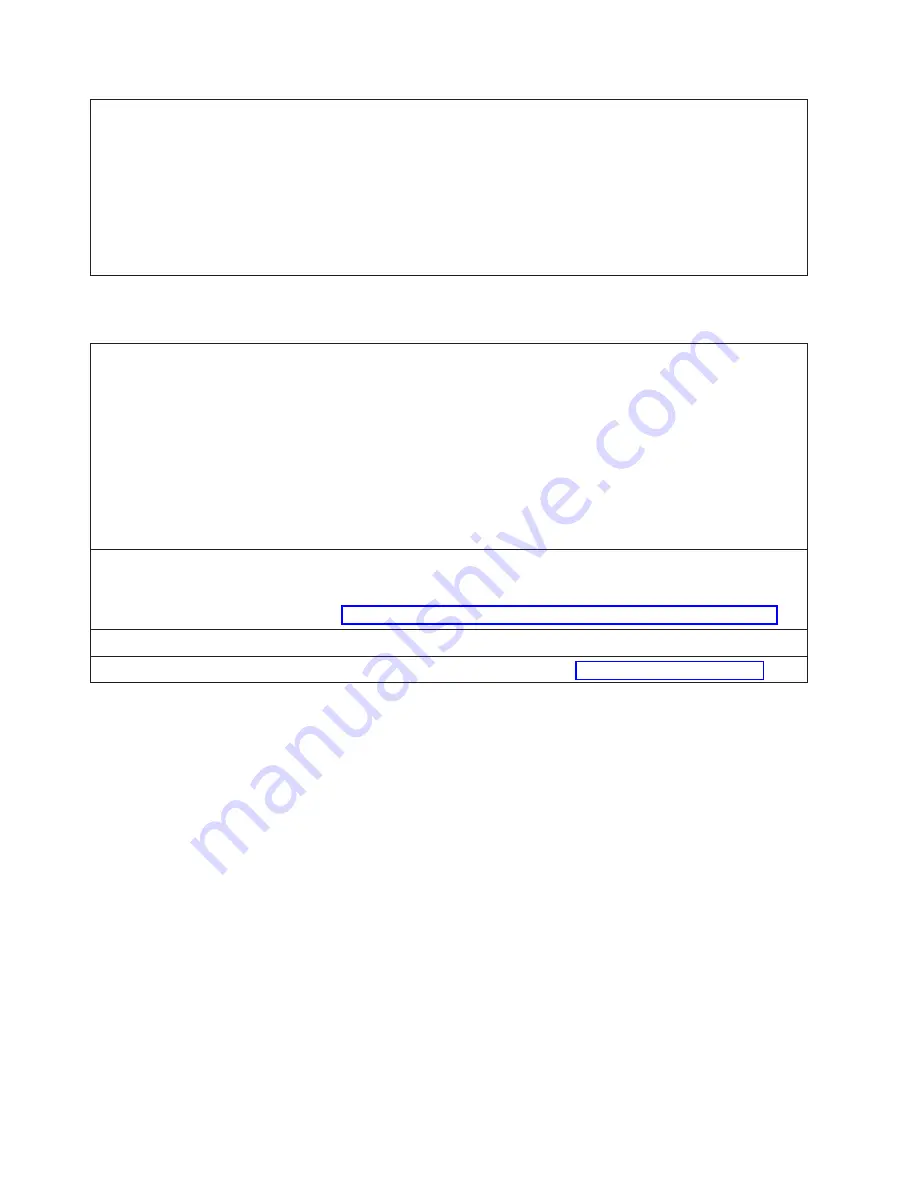

Model T42 Rack

Dimensions

Height

2015 mm 79.3 in.

Capacity

42 EIA Units

With PDP - DC only

Not applicable

Width without side panels

623 mm 24.5 in.

With side panels

644 mm 25.4 in.

Depth with rear door only

1042 mm 41.0 in.

Depth with rear door and

RS/6000 style front door

1098 mm 43.3 in.

pSeries (sculptured) style

front door

1147 mm 45.2 in.

Weight

Base Rack

261 kg 575 lbs.

Full Rack

¹

930 kg 2045 lbs

See “T00 and T42 Rack Weight Distribution and Floor Loading” on page 35.

Service Clearance

Recommended minimum vertical service clearance from floor is 2439 mm or 8 feet.

All Other Specifications

For all other technical information, see the table for “Model T00 Rack” on page 31.

32

Site and Hardware Planning Information

Summary of Contents for 7012 397

Page 1: ...RS 6000 and Eserver pSeries Site and Hardware Planning Information SA38 0508 20...

Page 2: ......

Page 3: ...RS 6000 and Eserver pSeries Site and Hardware Planning Information SA38 0508 20...

Page 11: ...Appendix Notices 385 Index 387 Contents ix...

Page 12: ...x Site and Hardware Planning Information...

Page 16: ...xiv Site and Hardware Planning Information...

Page 18: ...xvi Site and Hardware Planning Information...

Page 26: ...8 Site and Hardware Planning Information...

Page 238: ...220 Site and Hardware Planning Information...

Page 246: ...228 Site and Hardware Planning Information...

Page 284: ...266 Site and Hardware Planning Information...

Page 296: ...278 Site and Hardware Planning Information...

Page 366: ...348 Site and Hardware Planning Information...

Page 372: ...Async Adapter Cable Planning Chart 354 Site and Hardware Planning Information...

Page 377: ...Standard I O Cable Planning Chart Chapter 12 Cable Planning 359...

Page 380: ...Cable Planning Chart Other Adapters 362 Site and Hardware Planning Information...

Page 384: ...366 Site and Hardware Planning Information...

Page 402: ...384 Site and Hardware Planning Information...

Page 404: ...386 Site and Hardware Planning Information...

Page 413: ......

Page 414: ...Printed in USA SA38 0508 20...

Page 415: ...Spine information RS 6000 and Eserver pSeries Site and Hardware Planning Information...