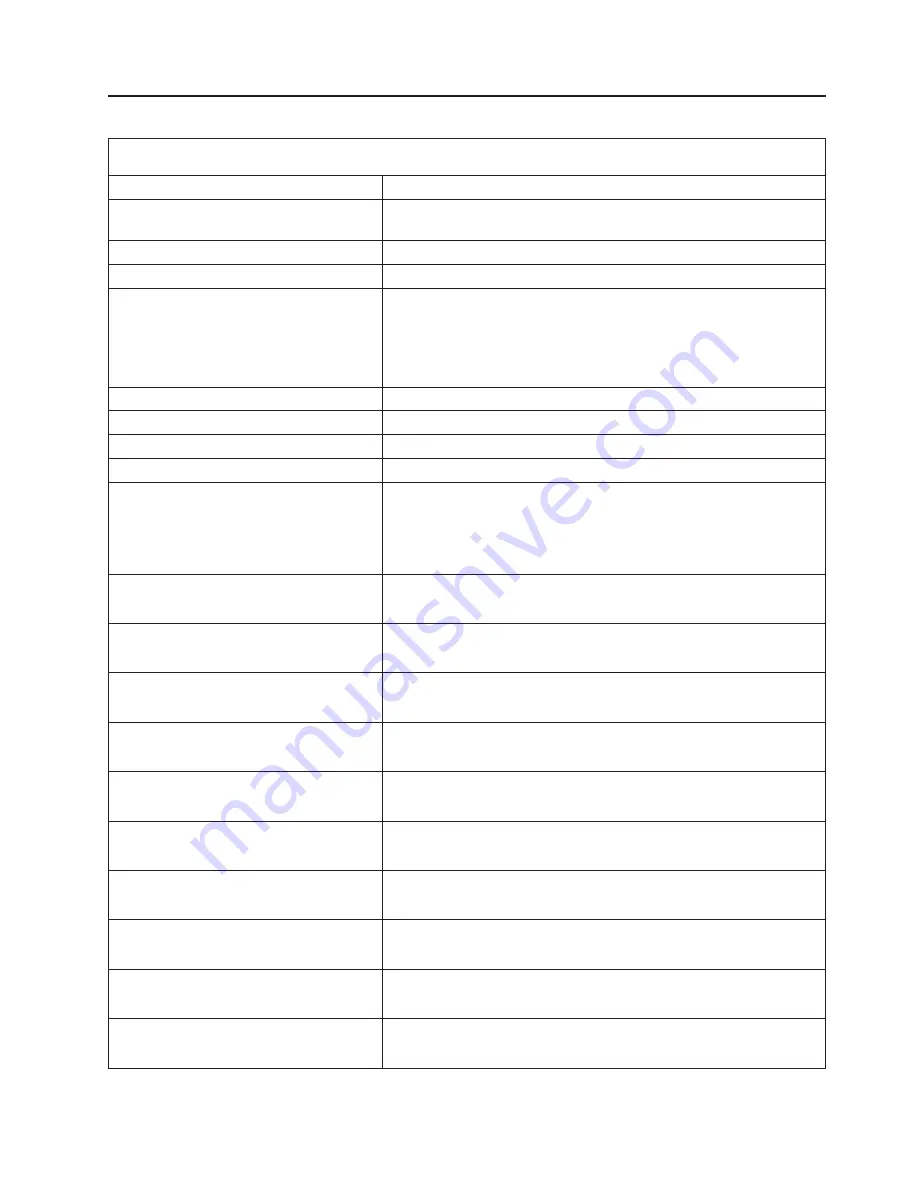

Power error messages

Note:

See Chapter 7, “Parts listing, BladeCenter Type 8677 and 1881,” on page 77 to determine which components

should be replaced by a field service technician.

Message

Action

Power module 3 or 4 is required to

power blades 7 to 14

Ensure power modules 3 and 4 are installed and connected to ac

power.

Power supply x fault

Replace power module x.

Power supply x 12V over voltage fault

Replace power module x.

Power supply x 12V over current fault

1.

An over current condition is typically caused by an external

load fault. Attempt to restart the faulted power module by

removing ac to the system components one at a time to isolate

the failing component.

2. Replace power module.

Power supply x 12V under voltage fault

Replace power module x.

Power supply x 12V current fault

Replace power module x.

Power supply x DC good fault

Replace power module x.

Power supply x removed

Reinstall power supply x.

System over recommended voltage for

+12V

1.

Reseat the management module.

2. Reseat the power modules.

3. Replace the power modules.

4. Replace the management module.

System over recommended voltage for

+1.8V

1.

Reseat the management module.

2. Replace the management module.

System over recommended voltage for

+2.5V

1.

Reseat the management module.

2. Replace the management module.

System over recommended voltage for

+3.3V

1.

Reseat the management module.

2. Replace the management module.

System over recommended voltage for

5V

1.

Reseat the management module.

2. Replace the management module.

System over recommended voltage for

+5V

1.

Reseat the management module.

2. Replace the management module.

System under recommended voltage for

+12V

1.

Reseat the management module.

2. Replace the management module.

System under recommended voltage for

+1.8V

1.

Reseat the management module.

2. Replace the management module.

System under recommended voltage for

+2.5V

1.

Reseat the management module.

2. Replace the management module.

System under recommended voltage for

3.3V

1.

Reseat the management module.

2. Replace the management module.

System under recommended voltage for

5V

1.

Reseat the management module.

2. Replace the management module.

Chapter 6. Symptom-to-FRU index

71

Summary of Contents for 8677 - BladeCenter Rack-mountable - Power...

Page 1: ...BladeCenter E Type 8677 and 1881 Hardware Maintenance Manual and Troubleshooting Guide...

Page 2: ......

Page 3: ...BladeCenter E Type 8677 and 1881 Hardware Maintenance Manual and Troubleshooting Guide...

Page 8: ...vi BladeCenter E Type 8677 and 1881 Hardware Maintenance Manual and Troubleshooting Guide...

Page 30: ...20 BladeCenter E Type 8677 and 1881 Hardware Maintenance Manual and Troubleshooting Guide...

Page 108: ...98 BladeCenter E Type 8677 and 1881 Hardware Maintenance Manual and Troubleshooting Guide...

Page 109: ...Laser Klass 1 Appendix B Related service information 99...

Page 110: ...100 BladeCenter E Type 8677 and 1881 Hardware Maintenance Manual and Troubleshooting Guide...

Page 111: ...Appendix B Related service information 101...

Page 112: ...102 BladeCenter E Type 8677 and 1881 Hardware Maintenance Manual and Troubleshooting Guide...

Page 113: ...Appendix B Related service information 103...

Page 128: ...118 BladeCenter E Type 8677 and 1881 Hardware Maintenance Manual and Troubleshooting Guide...

Page 129: ...Appendix B Related service information 119...

Page 130: ...120 BladeCenter E Type 8677 and 1881 Hardware Maintenance Manual and Troubleshooting Guide...

Page 131: ...Appendix B Related service information 121...

Page 132: ...122 BladeCenter E Type 8677 and 1881 Hardware Maintenance Manual and Troubleshooting Guide...

Page 138: ...128 BladeCenter E Type 8677 and 1881 Hardware Maintenance Manual and Troubleshooting Guide...

Page 148: ...138 BladeCenter E Type 8677 and 1881 Hardware Maintenance Manual and Troubleshooting Guide...

Page 149: ......

Page 150: ...Part Number 49Y0145 Printed in USA 1P P N 49Y0145...