Maintenance

5-16

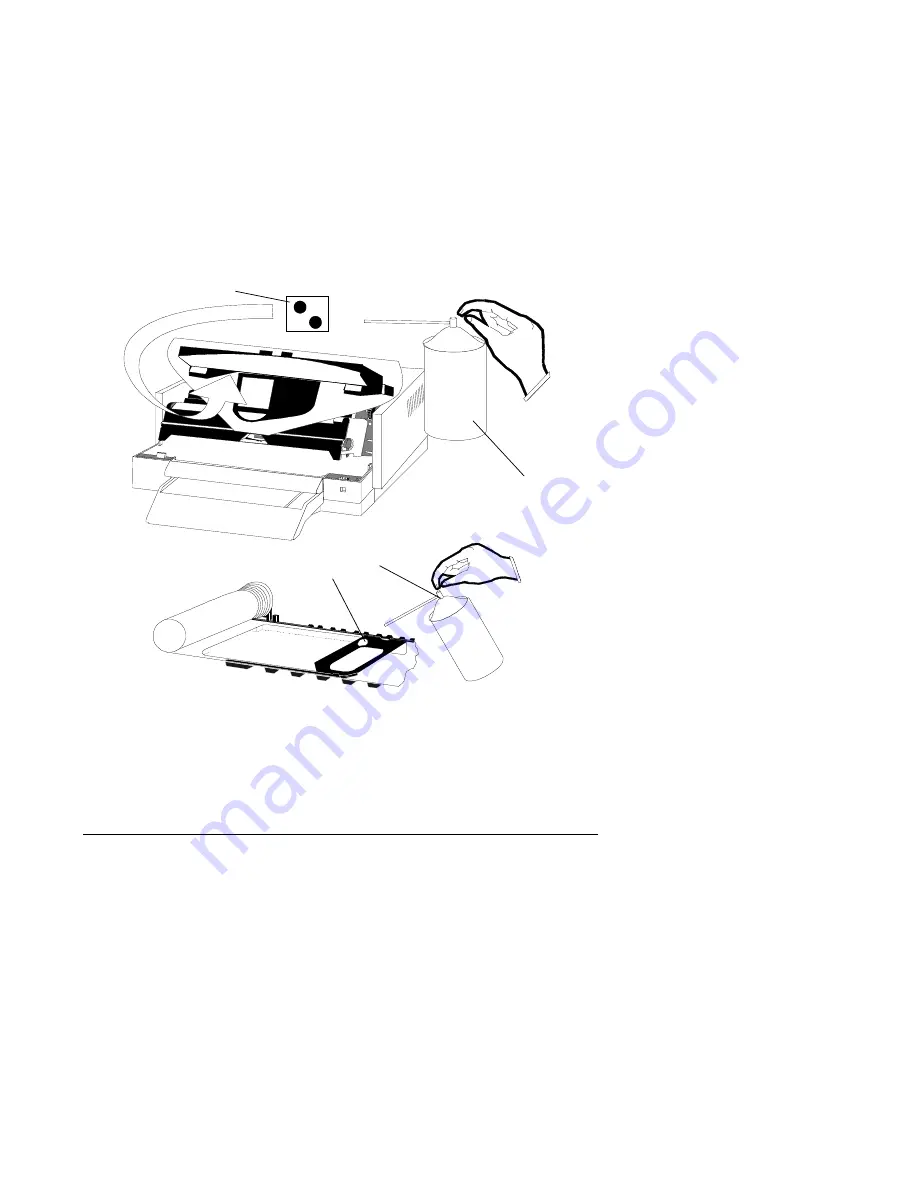

5.4 Cleaning of Edge Detection Sensor and Mylar Slide

Hole

These should be cleaned when the Ink Ribbon Cassette is changed.

Note: if pressurized air is not available a Lint Free cloth may be used.

If necessary, refer to the Ink Ribbon Cassette and Mylar Cassette procedure

1

Pressurized Air Can

-

position the can near the sensor

and release air

2

Pressurized Air Can

-

position the nozzle near the

Slide Hole and release air

1

Sensor

Mylar Slide Hole

2