Power 775 D-Link Service Procedure

PN: 41U8487, EC N44172

9 of 27

2.3.1

General Discussion of MTP Optical Connector Handling

The MTP implementation of the MPO (Multi-Fiber Push-on/Pull-off) optical connector is a robust, rugged

optical connector with a long record of service worldwide over nearly two decades. However, there are several

factors that will greatly improve the effectiveness in using this optical connector.

CLEANLINESS IS CRITICAL

. Operation of an optical connector requires precise end-to-end alignment of

the two optical fibers, with little or no air gap in between. Fiber ends are pushed together with force of about 2

pounds, to minimize likelihood of air gaps. If dust or hair gets on the ends of the connectors, where the optical

fibers exit, it may block the light passing between fibers, or may push ferrules apart, causing larger gaps

between fibers. Therefore, it is important that the ends of the connectors are either kept clean, or are actively

cleaned before each connection. The following steps will help assure cleanliness, and will help ensure proper

signal integrity on all fiber lanes.

•

Leave dust caps and dust covers on connectors and ports as much as possible,

•

Ensure to never touch the end surfaces of the connectors, and

•

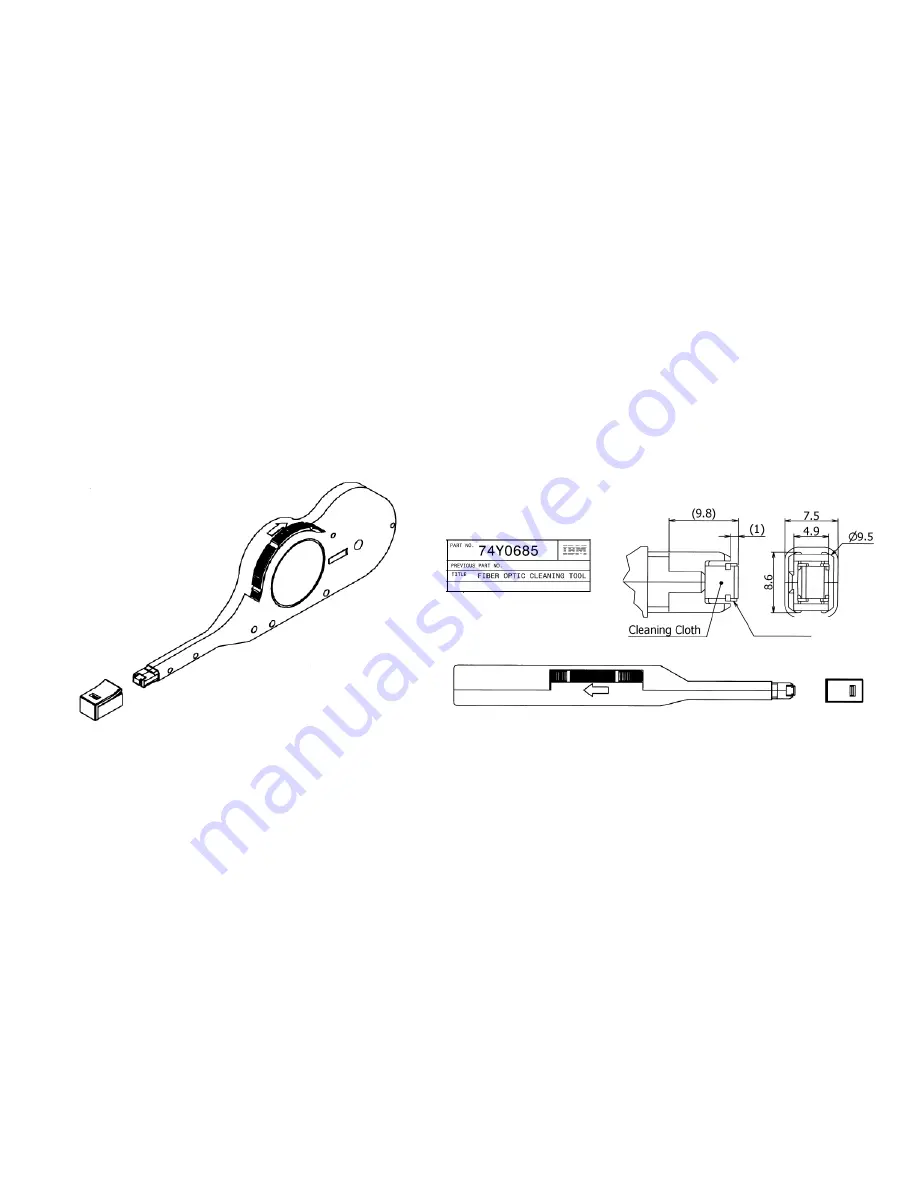

Regularly use approved cleaning tools, such as the Fiber Optic Cleaning Tool shown below, preferably

before each and every connector insertion.

DON’T FORCE IT.

The Groupers, Push/Pull Tabs, and MTP Connector housings are made of plastic. The

plastic is high-quality, robust, and non-brittle, but parts may break if pushed or pulled too hard. Also, the PVC

cable jacket may separate from the connector housing, if it is pulled too hard. No operation in the insertion or

removal of an individual connector should require more than about 1 kilogram (9.8 Newtons / 2 pound) of

force – roughly equivalent to turning a doorknob. Always use the blue purple colored Push/Pull tabs for doing

the final actuation of connectors, both on insertion and removal.

LISTEN & FEEL FOR THE CLICKS.

MTP optical connectors operate in two steps: 1. Initial actuation,

where the connector is aligned with the LR-Port receptacle and pushed partway in, and 2. Final actuation,

where the latching fingers push the spring-loaded latching sleeve back, then ride over two latching nubs, and,

when past the latching nubs, release the spring-loaded latching sleeve so that it can slide over the latching

fingers. When this happens, there is an audible “click” as the latching sleeve hits its end of travel. If there is

not a “click”, the connector is not fully connected, the fiber ends are not pressed together, and the connector

will not pass light well. Similarly, on removal, there is another “click”, as the spring-loaded latching sleeve is

pulled back, releasing the latching fingers, and they snap over the latching nubs. On insertion of a LR-Link 8-

connector grouper, all connectors go through the initial actuation as a group. The final actuation is done

individually -- 8 push/pull tabs must be pushed separately, yielding 8 separate audible “clicks”, for the whole

grouper to be fully connected. On removal, all 8 push/pull tabs must be pulled, yielding 8 separate audible

“clicks”, before the grouper can be removed from the row of ports.

Blue Head