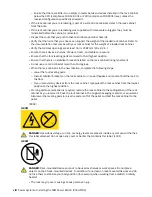

CAUTION:

Enclosure Integrity.

• Access covers are intended only for occasional removal.

• Follow documented procedures when opening during live or temporary service.

• When service is complete, promptly reinstall all covers, lids, and/or doors for correct operation.

(L031)

All lasers are certified in the U.S. to conform to the requirements of DHHS 21 CFR Subchapter J for class

1 laser products. Outside the U.S., they are certified to be in compliance with IEC 60825 as a class 1 laser

product. Consult the label on each part for laser certification numbers and approval information.

CAUTION: This product might contain one or more of the following devices: CD-ROM drive, DVD-

ROM drive, DVD-RAM drive, or laser module, which are Class 1 laser products. Note the following

information:

• Do not remove the covers. Removing the covers of the laser product could result in exposure to

hazardous laser radiation. There are no serviceable parts inside the device.

• Use of the controls or adjustments or performance of procedures other than those specified

herein might result in hazardous radiation exposure.

(C026)

CAUTION: Data processing environments can contain equipment transmitting on system links with

laser modules that operate at greater than Class 1 power levels. For this reason, never look into

the end of an optical fiber cable or open receptacle. Although shining light into one end and looking

into the other end of a disconnected optical fiber to verify the continuity of optic fibers may not

injure the eye, this procedure is potentially dangerous. Therefore, verifying the continuity of optical

fibers by shining light into one end and looking at the other end is not recommended. To verify

continuity of a fiber optic cable, use an optical light source and power meter. (C027)

CAUTION: This product contains a Class 1M laser. Do not view directly with optical instruments.

(C028)

CAUTION: Some laser products contain an embedded Class 3A or Class 3B laser diode. Note the

following information:

• Laser radiation when open.

• Do not stare into the beam, do not view directly with optical instruments, and avoid direct

exposure to the beam. (C030)

(C030)

CAUTION: The battery contains lithium. To avoid possible explosion, do not burn or charge the

battery.

Do Not:

• Throw or immerse into water

• Heat to more than 100 degrees C (212 degrees F)

• Repair or disassemble

Safety notices xi

Summary of Contents for Power E1050

Page 1: ...Power Systems Installing the IBM Power E1050 9043 MRX IBM GI11 0003 00...

Page 4: ...iv...

Page 14: ...xiv Power Systems Installing the IBM Power E1050 9043 MRX...

Page 36: ...22 Power Systems Installing the IBM Power E1050 9043 MRX...

Page 47: ......

Page 48: ...IBM Part Number 03KG355 GI11 0003 00 1P P N 03KG355...