– For racks with a DC power distribution panel (PDP), turn off the circuit breaker that controls

the power to the system unit(s), or disconnect the customer’s DC power source, when directed

to disconnect power during servicing.

• Connect all devices installed in a rack cabinet to power devices installed in the same rack

cabinet. Do not plug a power cord from a device installed in one rack cabinet into a power device

installed in a different rack cabinet.

• An electrical outlet that is not correctly wired could place hazardous voltage on the metal parts

of the system or the devices that attach to the system. It is the responsibility of the customer to

ensure that the outlet is correctly wired and grounded to prevent an electrical shock. (R001 part

1 of 2)

(R001 part 2 of 2):

CAUTION:

• Do not install a unit in a rack where the internal rack ambient temperatures will exceed the

manufacturer's recommended ambient temperature for all your rack-mounted devices.

• Do not install a unit in a rack where the air flow is compromised. Ensure that air flow is not

blocked or reduced on any side, front, or back of a unit used for air flow through the unit.

• Consideration should be given to the connection of the equipment to the supply circuit so that

overloading of the circuits does not compromise the supply wiring or overcurrent protection.

To provide the correct power connection to a rack, refer to the rating labels located on the

equipment in the rack to determine the total power requirement of the supply circuit.

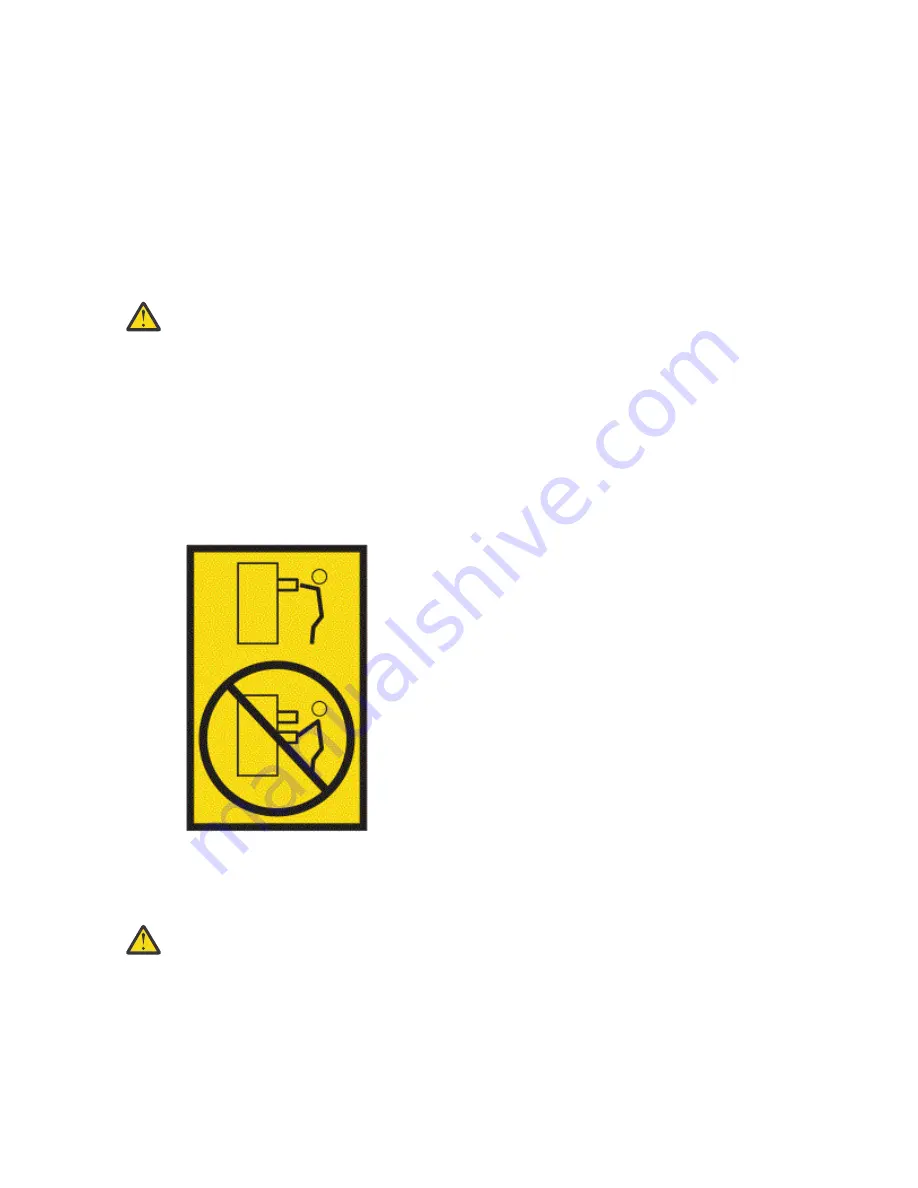

• (For sliding drawers.) Do not pull out or install any drawer or feature if the rack stabilizer brackets

are not attached to the rack or if the rack is not bolted to the floor. Do not pull out more than one

drawer at a time. The rack might become unstable if you pull out more than one drawer at a time.

• (For fixed drawers.) This drawer is a fixed drawer and must not be moved for servicing unless

specified by the manufacturer. Attempting to move the drawer partially or completely out of the

rack might cause the rack to become unstable or cause the drawer to fall out of the rack. (R001

part 2 of 2)

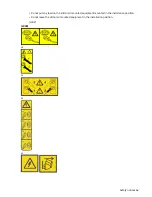

CAUTION: Removing components from the upper positions in the rack cabinet improves rack

stability during relocation. Follow these general guidelines whenever you relocate a populated rack

cabinet within a room or building.

• Reduce the weight of the rack cabinet by removing equipment starting at the top of the rack

cabinet. When possible, restore the rack cabinet to the configuration of the rack cabinet as you

received it. If this configuration is not known, you must observe the following precautions:

– Remove all devices in the 32U position and above.

– Ensure that the heaviest devices are installed in the bottom of the rack cabinet.

Safety notices vii

Summary of Contents for Power System System E950

Page 1: ...Power Systems NVMe U 2 drives for the 9040 MR9 IBM...

Page 4: ...iv...

Page 14: ...xiv Power Systems NVMe U 2 drives for the 9040 MR9...

Page 18: ...or or or or 4 Power Systems NVMe U 2 drives for the 9040 MR9...

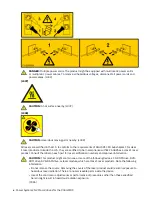

Page 26: ...Figure 9 Removing the power cords L003 or or 12 Power Systems NVMe U 2 drives for the 9040 MR9...

Page 44: ...30 Power Systems NVMe U 2 drives for the 9040 MR9...

Page 55: ......

Page 56: ...IBM...