4.

Install

the

left

and

right

BPE

rails,

(item

3

in

the

illustration

on

page

183).

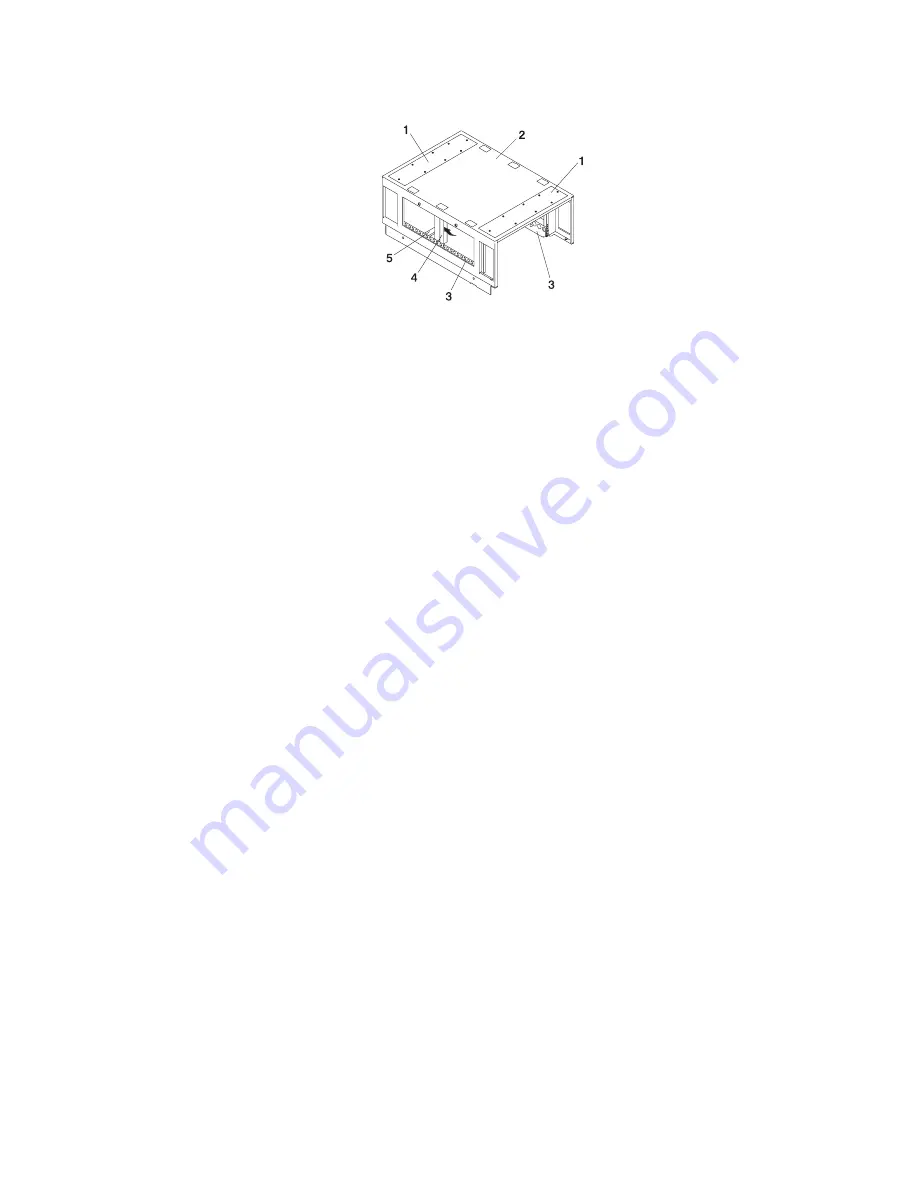

1

Front

and

Rear

Rack

Top

Frame

Top

Panels

4

Foam

and

Metal

Air

Baffle

2

Rack

Top

Frame

5

Rack

Top

Frame

Cross

Brace

3

Left

and

Right

BPE

Rails

5.

Insert

and

align

the

foam

and

metal

air

baffle

(item

4

in

the

illustration

on

page

183)

to

the

left

side

of

the

rack

top

frame,

securing

it

in

place

with

a

screw.

6.

Install

the

rack

top-frame

cross

brace

(item

5

in

the

illustration

on

page

176).

7.

Install

the

front

and

rear

BPEs.

Refer

to

the

illustration

on

page

176.

8.

Install

the

BPRs

as

follows:

a.

Make

sure

the

ON/OFF

switch

is

in

the

UNLOCK/OFF

position.

b.

Push

the

BPR

straight

into

the

Bulk

Power

Enclosure

(BPE).

c.

Tighten

the

thumbscrew

on

each

side

of

the

BPR,

using

the

torque

tool

(part

number

6422789).

d.

Rotate

the

release

levers

down

on

each

side

of

the

BPR.

e.

Repeat

for

the

other

BPRs.

There

can

be

up

to

six

BPRs,

with

three

in

front

and

three

in

back.

9.

Install

the

Bulk

Power

Controllers

(BPCs)

as

follows:

a.

Push

the

BPC

straight

into

the

Bulk

Power

Enclosure

(BPE).

b.

Tighten

the

thumbscrew

on

each

side

of

the

BPC,

using

the

torque

tool

(part

number

6422789).

c.

Repeat

for

the

other

BPCs.

There

are

two

BPCs,

with

one

in

front

and

one

in

back.

10.

Install

the

BPDs

as

follows:

a.

Push

the

BPD

straight

into

the

Bulk

Power

Enclosure

(BPE).

b.

Tighten

the

thumbscrew

on

each

side

of

the

BPD,

using

the

torque

tool

(part

number

6422789).

c.

Repeat

for

the

other

BPDS.

There

can

be

up

to

four

BPDs,

with

two

in

front

and

two

in

back.

11.

Install

the

BPFs

as

follows:

Note:

A

grille

covers

the

fan

on

the

front

of

the

fan

assembly.

a.

Locate

the

BPF

to

be

installed.

b.

Install

the

fan

cover

plate.

c.

Push

the

BPF

straight

out

of

the

BPE.

d.

Tighten

the

upper

and

lower

fasteners,

using

the

torque

tool

(part

number

6422789).

e.

Repeat

for

the

other

BPF.

There

are

two

BPFs,

one

in

front

and

one

in

back.

12.

For

the

reduced-height

option,

remove

the

front

and

rear

upper

shipping

bars

(item

1

in

the

following

illustration).

Appendix

I.

Removing

and

Installing

the

Rack

Top

Frame

183

Summary of Contents for pseries 655

Page 1: ...pSeries 655 Installation Guide SA38 0616 03 ERserver...

Page 2: ......

Page 3: ...pSeries 655 Installation Guide SA38 0616 03 ERserver...

Page 14: ...xii Eserver pSeries 655 Installation Guide...

Page 22: ...6 Eserver pSeries 655 Installation Guide...

Page 54: ...38 Eserver pSeries 655 Installation Guide...

Page 101: ...2 1 1 Top of Cassette 2 Handle Chapter 4 Installation and Removal Procedures 85...

Page 125: ...1 Metal EMC Shield 2 Adapter Bracket Chapter 4 Installation and Removal Procedures 109...

Page 128: ...112 Eserver pSeries 655 Installation Guide...

Page 132: ...116 Eserver pSeries 655 Installation Guide...

Page 156: ...140 Eserver pSeries 655 Installation Guide...

Page 204: ...188 Eserver pSeries 655 Installation Guide...

Page 211: ......

Page 212: ...Part Number 80P3836 Printed in USA February 2004 SA38 0616 03 1P P N 80P3836...