Service

Inspection

Guide

Perform

a

service

inspection

on

the

system

when:

v

The

system

is

inspected

for

a

maintenance

agreement.

v

Service

is

requested

and

service

has

not

recently

been

performed.

v

An

alterations

and

attachments

review

is

performed.

v

Changes

have

been

made

to

the

equipment

that

may

affect

its

safe

operation.

v

External

devices

with

their

own

power

cables

have

those

cables

attached.

If

the

inspection

indicates

an

unacceptable

safety

condition,

the

condition

must

be

corrected

before

anyone

can

service

the

machine.

Note:

The

owner

of

the

system

is

responsible

to

correct

any

unsafe

conditions.

Perform

the

following

checks:

1.

Check

the

covers

for

sharp

edges

and

for

damage

or

alterations

that

expose

the

internal

parts

of

the

system

unit.

2.

Check

the

covers

for

proper

fit

to

the

system

unit.

They

should

be

in

place

and

secure.

3.

Gently

rock

the

system

unit

from

side

to

side

to

determine

if

it

is

steady.

4.

Set

the

power

switch

of

the

system

unit

to

Off.

5.

Remove

the

covers.

6.

Check

for

alterations

or

attachments.

If

there

are

any,

check

for

obvious

safety

hazards,

such

as

broken

wires,

sharp

edges,

or

broken

insulation.

7.

Check

the

internal

cables

for

damage.

8.

Check

for

dirt,

water,

and

any

other

contamination

within

the

system

unit.

9.

Check

the

voltage

label

on

the

back

of

the

system

unit

to

ensure

that

it

matches

the

voltage

at

the

outlet.

10.

Check

the

external

power

cable

for

damage.

11.

With

the

external

power

cable

connected

to

the

system

unit,

check

for

0.1

ohm

or

less

resistance

between

the

ground

lug

on

the

external

power

cable

plug

and

the

metal

frame.

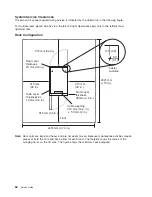

12.

Perform

the

following

checks

on

each

device

that

has

its

own

power

cables:

a.

Check

for

damage

to

the

power

cord.

b.

Check

for

the

correct

grounded

power

cable.

c.

With

the

external

power

cable

connected

to

the

device,

check

for

0.1

ohm

or

less

resistance

between

the

ground

lug

on

the

external

power

cable

plug

and

the

metal

frame

of

the

device.

13.

Install

the

covers.

Chapter

1.

Reference

Information

65

Summary of Contents for RS/6000 Enterprise Server M80

Page 1: ...RS 6000 Enterprise Server Model M80 Eserver pSeries 660 Model 6M1 Service Guide SA38 0571 01...

Page 10: ...x Service Guide...

Page 14: ...xiv Service Guide...

Page 16: ...xvi Service Guide...

Page 22: ...Data Flow 4 Service Guide...

Page 30: ...CEC Card Cage Rear of CEC drawer viewed from top cover removed 12 Service Guide...

Page 84: ...66 Service Guide...

Page 176: ...158 Service Guide...

Page 376: ...358 Service Guide...

Page 430: ...412 Service Guide...

Page 485: ...Chapter 11 Parts Information This chapter contains parts information for the system 467...

Page 486: ...CEC Drawer Card Assembly 9 468 Service Guide...

Page 488: ...CEC Drawer Backplane 5 2a 1 2 3 4 470 Service Guide...

Page 490: ...CEC Drawer Power Supplies 1 2 3 4 5 6 7 8 9 472 Service Guide...

Page 492: ...CEC Drawer Fan Assemblies 2 1 3 4 5 6 8 9 10 11 12 13 7 14 474 Service Guide...

Page 496: ...7 8 9 10 6 1 2 3 4 4 5 478 Service Guide...

Page 508: ...490 Service Guide...

Page 520: ...502 Service Guide...

Page 522: ...504 Service Guide...

Page 526: ...508 Service Guide...

Page 558: ...540 Service Guide...

Page 565: ......