Cartridge

Compatibility

Table

8-1.

Ultrium

data

cartridge

compatibility

with

Ultrium

3

tape

drive

IBM

Ultrium

Tape

Drive

IBM

TotalStorage

LTO

Ultrium

Data

Cartridges

400

GB

(Ultrium

3)

400

GB

WORM

200

GB

(Ultrium

2)

100

GB

(Ultrium

1)

Ultrium

3

Read/Write

Read/Write

Read

only

Data

Cartridge

When

processing

tape

in

the

cartridges,

Ultrium

Tape

Drives

use

a

linear,

serpentine

recording

format.

The

Ultrium

3

drive

reads

and

writes

data

on

704

tracks,

sixteen

tracks

at

a

time.

The

first

set

of

tracks

)

is

written

from

near

the

beginning

of

the

tape

to

near

the

end

of

the

tape.

The

head

then

repositions

to

the

next

set

of

tracks

for

the

return

pass.

This

process

continues

until

all

tracks

are

written

and

the

cartridge

is

full,

or

until

all

data

is

written.

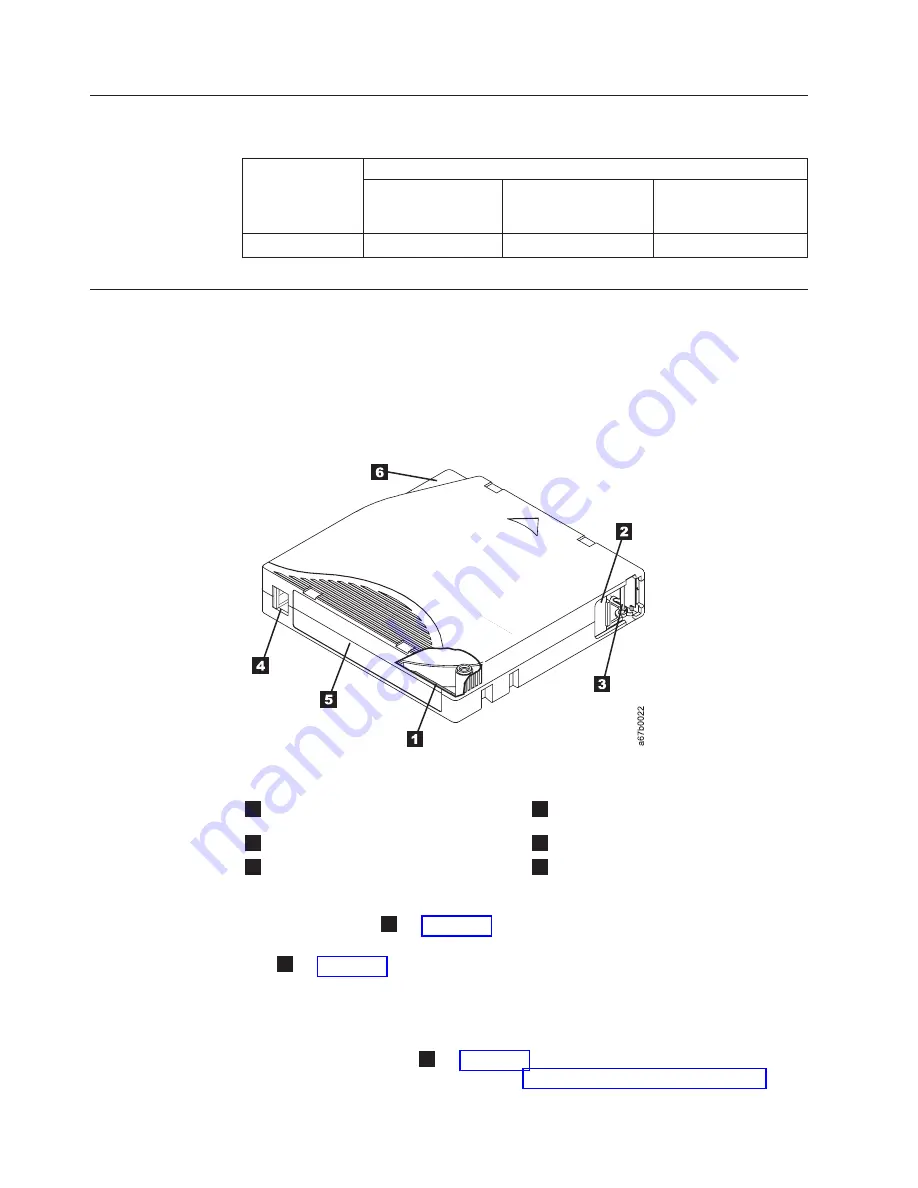

1

LTO

cartridge

memory

(cut-away

view)

4

Write-protect

Switch

2

Cartridge

door

5

Label

area

3

Leader

Pin

6

Insertion

guide

The

cartridge

door

(

2

in

protects

the

tape

from

contamination

when

the

cartridge

is

out

of

the

drive.

Behind

the

door,

the

tape

is

attached

to

a

leader

pin

(

3

in

When

the

cartridge

is

inserted

into

the

drive,

a

threading

mechanism

pulls

the

pin

(and

tape)

out

of

the

cartridge,

across

the

drive

head,

and

onto

a

non-removable

take-up

reel.

The

head

can

then

read

or

write

data

from

or

to

the

tape.

The

write-protect

switch

(

4

in

prevents

data

from

being

written

to

the

tape

cartridge.

For

more

information,

see

Figure

8-1.

The

IBM

TotalStorage

LTO

Ultrium

400

GB

Data

Cartridge

8-2

TS3310

Tape

Library

Setup

and

Operator

Guide

Summary of Contents for System Storage TS3310

Page 1: ...IBM System Storage TS3310 Tape Library Setup and Operator Guide GA32 0477 00...

Page 2: ......

Page 3: ...IBM System Storage TS3310 Tape Library Setup and Operator Guide GA32 0477 00...

Page 6: ...iv TS3310 Tape Library Setup and Operator Guide...

Page 12: ...x TS3310 Tape Library Setup and Operator Guide...

Page 14: ...xii TS3310 Tape Library Setup and Operator Guide...

Page 22: ...xx TS3310 Tape Library Setup and Operator Guide...

Page 24: ...xxii TS3310 Tape Library Setup and Operator Guide...

Page 42: ...1 18 TS3310 Tape Library Setup and Operator Guide...

Page 54: ...2 12 TS3310 Tape Library Setup and Operator Guide...

Page 63: ...a66ug019 Figure 3 6 Rails installed in rack front view Chapter 3 Installing the Library 3 9...

Page 78: ...3 24 TS3310 Tape Library Setup and Operator Guide...

Page 86: ...4 8 TS3310 Tape Library Setup and Operator Guide...

Page 98: ...5 12 TS3310 Tape Library Setup and Operator Guide...

Page 106: ...6 8 TS3310 Tape Library Setup and Operator Guide...

Page 220: ...11 22 TS3310 Tape Library Setup and Operator Guide...

Page 226: ...12 6 TS3310 Tape Library Setup and Operator Guide...

Page 236: ...A 10 TS3310 Tape Library Setup and Operator Guide...

Page 240: ...B 4 TS3310 Tape Library Setup and Operator Guide...

Page 266: ...F 8 TS3310 Tape Library Setup and Operator Guide...

Page 273: ......

Page 274: ...Part Number 95P2271 Printed in USA GA32 0477 00 1P P N 95P2271...