Attention: DO NOT TOUCH THE OUTER GUIDE RAIL ( 2 in

). THIS RAIL IS VERY DELICATE AND EASILY DAMAGED.

1. From the takeup reel, pull an arm 's length of tape around the rear of the tape path and over the head and rollers on the left side of the drive.

2. Set the drive on its left side with the head and tape path facing up.

3. Make sure that the tape is not twisted. Untwist tape if required.

4. Moisten a cotton swab with water and wet approximately 13 mm (0.5 in.) of the tape end and feed it onto the supply reel (inside the cartridge).

5. Turn the supply reel ( 4 in

) clockwise, allowing the moistened tape to adhere to the hub as it winds around the supply reel (inside the cartridge).

Figure 1. Rewinding tape into cartridge

1

Loader motor worm gear

3

Takeup reel motor

2

Outer guide rail

WARNING: DO NOT TOUCH

4

Supply reel motor

6. Continue spooling into the cartridge until the tape is taut and remains within the flanges of the tape guiding rollers. Turn the supply reel ( 4 in

) 10

more turns. Ensure that you do not stretch the tape.

7. Reassemble the drive, reversing the steps in

.

8. Reassemble the drive chassis, following the steps in

Replacing the internal drive

.

9. Reinstall the drive canister into the cradle assembly. Ensure that the connector on the drive is seated properly into the connector on the cradle.

10. Allow the drive to complete mid-tape recovery. This action takes several minutes. When this activity completes, push Unload to eject the cartridge.

11. Test the drive (see

Function code 1: Run drive diagnostics

) to determine if it needs to be replaced.

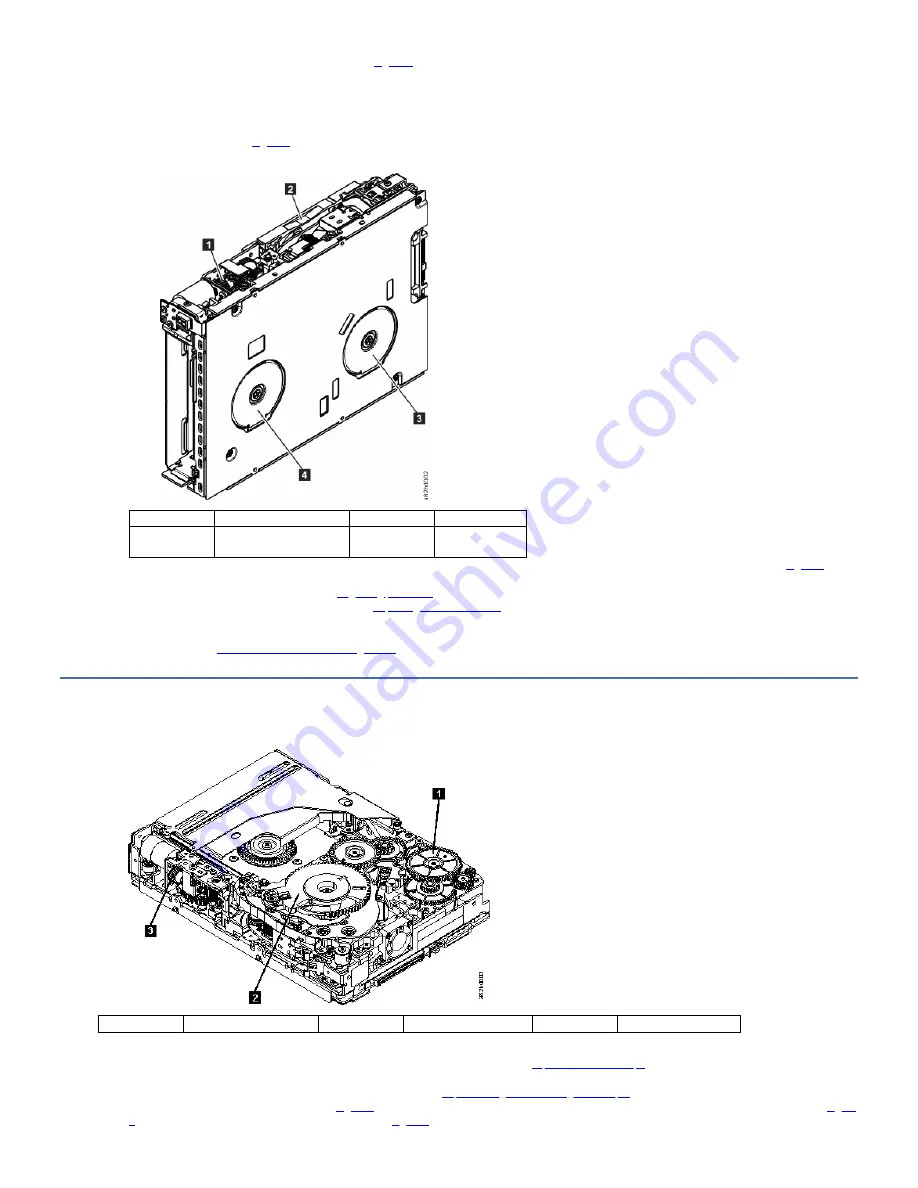

Tape pulled from or broken near leader pin

Figure 1. Drive with cover removed to reveal gear train.

1

Threader intermediate gear 2

Threader mechanism gear 3

Loader motor worm gear

1. Pull out tape from the takeup reel.

Note: If there is more than approximately 0.6 m (2 ft.) of tape on the takeup reel, go to

2. If there is less than approximately 0.6 m (2 ft.) of tape on the takeup reel, cut off the excess tape as close to the leader pin as possible.

3. Reattach the leader pin to the remaining tape. For instructions, see

Repositioning or reattaching a leader pin

4. Locate the threader intermediate gear ( 1 in

) near the rear of the drive. You can use your finger to rotate the threader intermediate gear ( 1 in

) and slowly rotate the threader mechanism gear ( 2 in

128

IBM TS22xx Tape Drives

Summary of Contents for TS22 Series

Page 1: ...IBM TS22xx Tape Drives IBM...