Maintenance

Deaeration Tank

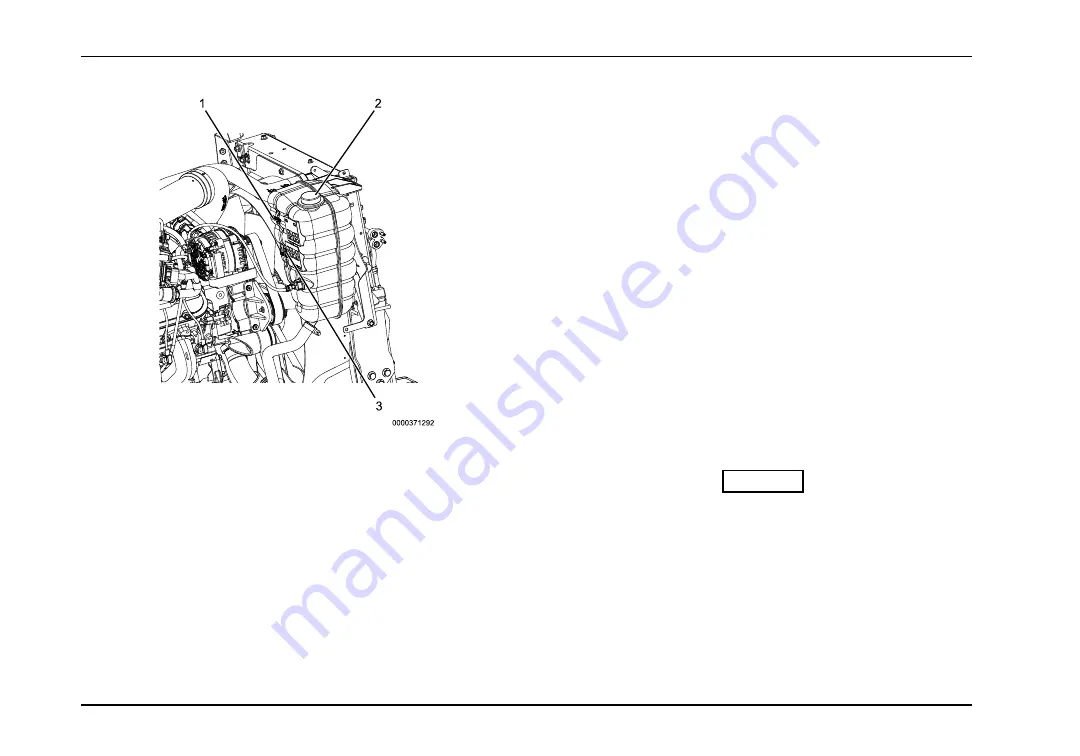

1.

COLD MAX Line

2.

Vented Fill Cap

3.

COLD MIN Line

To function properly, the coolant system must be completely filled

with coolant and all air must be expelled. To accomplish this, the

following procedures should be carefully completed:

1.

Open any shutoff valve in the heater circuit, in-transit heat

circuit, or Auxiliary Power Unit (APU) circuit (not shown).

2.

Open the cooling system vent valve (where applicable) on

the top radiator pipe.

3.

Fill the deaeration tank with the proper coolant to the top of

tank.

4.

Close cooling system vent valve when air is purged and

coolant is seen flowing from valve.

5.

To purge air from the cooling system, start engine and run at

an elevated idle (1,500 rpm) for approximately 10 minutes.

6.

Verify coolant concentration and adjust coolant level to the

COLD MAX level.

7.

Install the deaeration tank cap once the coolant is stabilized

at the COLD MAX level.

8.

Verify the coolant is at the correct level and concentration.

9.

Inspect and adjust the coolant level as necessary, prior to

daily operation.

Coolant Concentration

CAUTION

To prevent vehicle and / or engine component

damage, always use the proper coolant to top off

the cooling system. Failure to do so may result in

the loss of coolant life properties.

It is required that the PSI 8.8L LPG engine uses Dex-Cool

®

Coolant in the cooling system. Dex-Cool

®

is a nitrite, nitrate,

phosphate, silicate, borate and amine-free formulation that

uses a patented carboxylate technology to provide maximum

172

Summary of Contents for BE Series

Page 4: ......

Page 11: ...Table of Contents Section 14 Index Index 215 vii ...

Page 12: ...Table of Contents viii ...

Page 52: ...Instrumentation Declination Zone Map 40 ...

Page 67: ...Driver Controls 55 ...

Page 68: ...Driver Controls 56 ...

Page 71: ...Driver Controls 59 ...

Page 144: ...Operation 132 ...

Page 151: ...Roadside Emergencies Body Fuse Circuit Breaker Panel 139 ...