EXCELDirect

®

4

Owner's Manual

Planning your installation

General

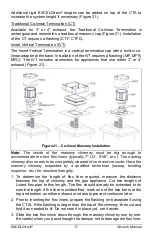

Prior to starting your installation, we suggest you take the following into

consideration:

1. There are two possible ways to connect a direct vent venting system to a gas

appliance:

- Horizontal installation (through the wall);

- Vertical installation (through the roof).

Check the appliance manufacturer's installation instructions to see all possible

vent configurations.

2. Review all your options for the appliance location and also venting configuration.

Try to minimize the alteration and reframing of structural components of the

building (wall studs, water pipes, electrical wiring, ceiling joists, roof rafters, etc.).

It may be easier to change the location of your appliance than to modify the

building structure.

3. Carefully read the appliance and the venting system instruction manuals. Good

planning might save you time, work and money.

4. Use only authorized EXCELDirect

®

listed components unless compatibility with

another brand is specified in the appliance manufacturer’s instructions. Do not use

damaged parts.

5. For a horizontal installation, you will have to take into consideration the distance

between the gas appliance adapter to the wall, as well as the wall thickness and

a vertical rise (if applicable). The horizontal vent termination on the exterior must

be located in accordance with the Installation Codes and Regulations. See

"horizontal and vertical terminal location" section on page 20.

6. For a vertical installation, you must consider the distance between the gas

appliance outlet and the ceiling, the ceiling thickness, the height of the attic or

second floor and allow sufficient vent height above roof line. See Table 1 and

Figure 11.

7. For two-story applications, firestops are required at each floor. If an offset is

needed in the attic, additional lengths and elbows will be required.

8. Contact your local building authority and/or fire officials for permits, restrictions

and installation inspections. You may also wish to contact your house insurance

representative.

Tool checklist

Tools and equipment you may need for your installation.

- Eye protection

- Gloves

- Tape Measure

- Extension cord

- Marking pencil

- Nails

- Stud sensor

- Square

- Circular saw

- Hand saw

- Drill

- Drill bits

- Keyhole saw

- Ladder

- Level

- Pliers

- Caulking gun

- Hi temp. Silicone sealant

- Hammer

- Screwdrivers

- Screws

- Plumb Bob

- Cold chisel

Summary of Contents for EXCELDirect

Page 22: ...EXCELDirect 22 Owner s Manual ...