Model VIP+

28

Owner's Manual

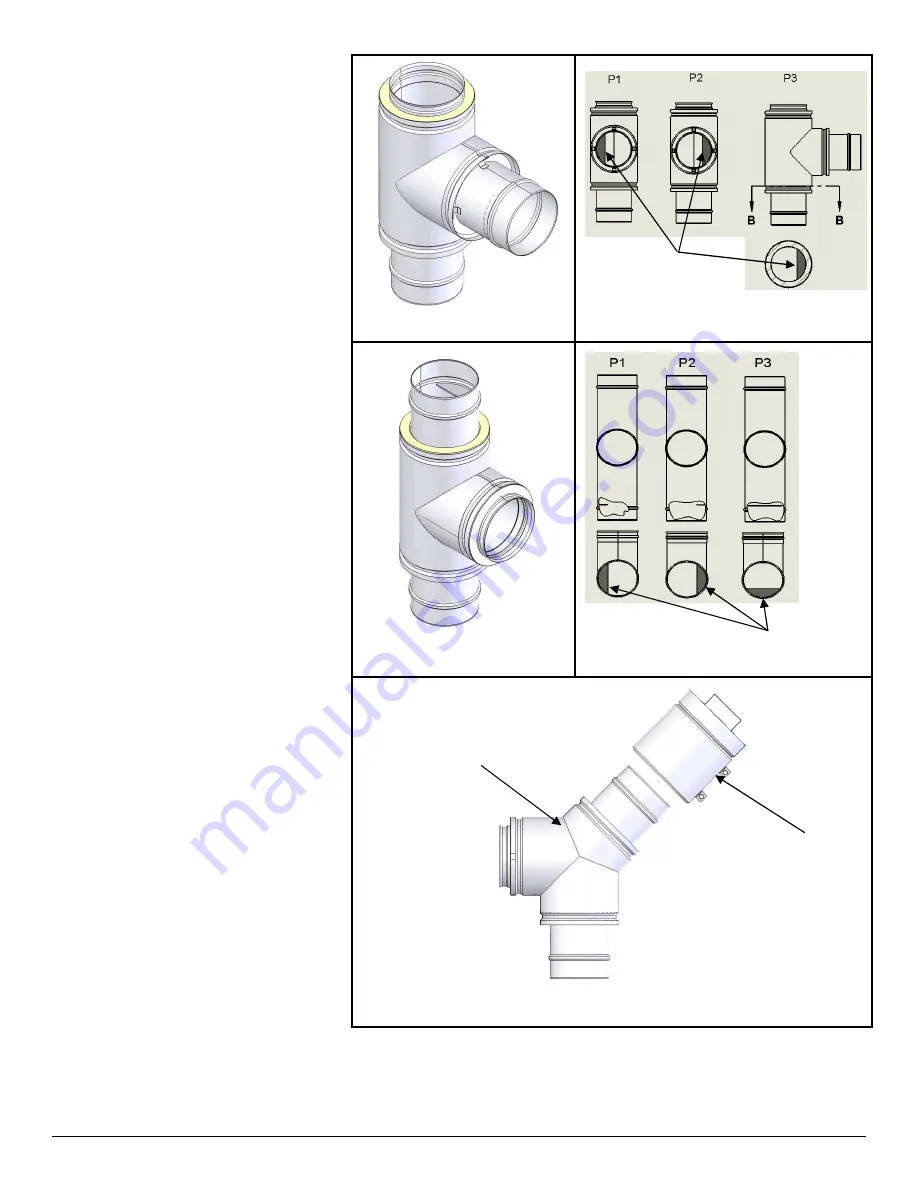

Wyes and Tees (Cleanout)

Special care must be taken when designing a

Grease Duct to provide access for cleanout and

comply with NFPA 96 requirements.

Inspection and cleanout points can be equipped with

a dam at the access port. The access port must be

closed with a tee cap and the grease dam prevents

grease spillage when opened. The location of the

access port in the tee is dependent on the orientation

of the tee in the final installation. Two types of tees

are available to cover all possible configurations and

insure that a grease dam can always be properly

positioned.

1)

T1 Grease Tee

(

Figure 44

) is your basic 90° Tee

fitted with a grease Dam. Refer to

Figure 45

for

dam position.

2)

T2 Grease Tee

(

Figure 46

) has inverted female

and male ends and covers mostly horizontal grease

dam configurations. Refer to

Figure 47

for dam

position.

When ordering you GreaseTee, please specify tee

type (T1 or T2) and dam position (P1, P2 or P3)

The Grease Duct Wye (

Figure 48

) is useful where

the grease duct must be accessed for clean-out and

inspection purposes. It can be used in place of the

T1 and T2 Grease Tee and combined with a Tee

Cap to provide easy access clearance at the end of

an horizontal run. See

Figure 49

for typical

installation.

The wyes and tees are attached and sealed to other

pipe sections in the same manner as described in

Chimney Joint Connection

Section.

A No-Tool Tee Cap is available to facilitate access

for inspection and cleanout.

Figure 44

Figure 45

Figure 46

Figure 47

Figure 48

Grease Duct

Wye

Tee Cap

T1 Optional

Dam Position

T2 Optional

Dam Position

T1

T2