operating & maintenance manual

–

console water source heat pump (wshp)

9

operating & maintenance manual

-

console water source heat pump (wshp)

DO NOT OPERATE UNIT WITHOUT FILTER.

This practice will damage and/or seriously impair

the performance of your unit and could void your

Warranty.

roomSiDe component cleaning

Evaporator Coil and Drain Pan / Drain Hoses

IMPORTANT NOTE: The power MUST be

disconnected to the unit before carrying out any of

the following cleaning!

To access the components within the roomside

section of the unit, disconnect the power to the unit

and then remove the unit chassis front cover by

unscrewing the #8 hex head retaining screws that

hold the front cover in place (use a ¼” hex head

driver). You will then have access to the following

components:

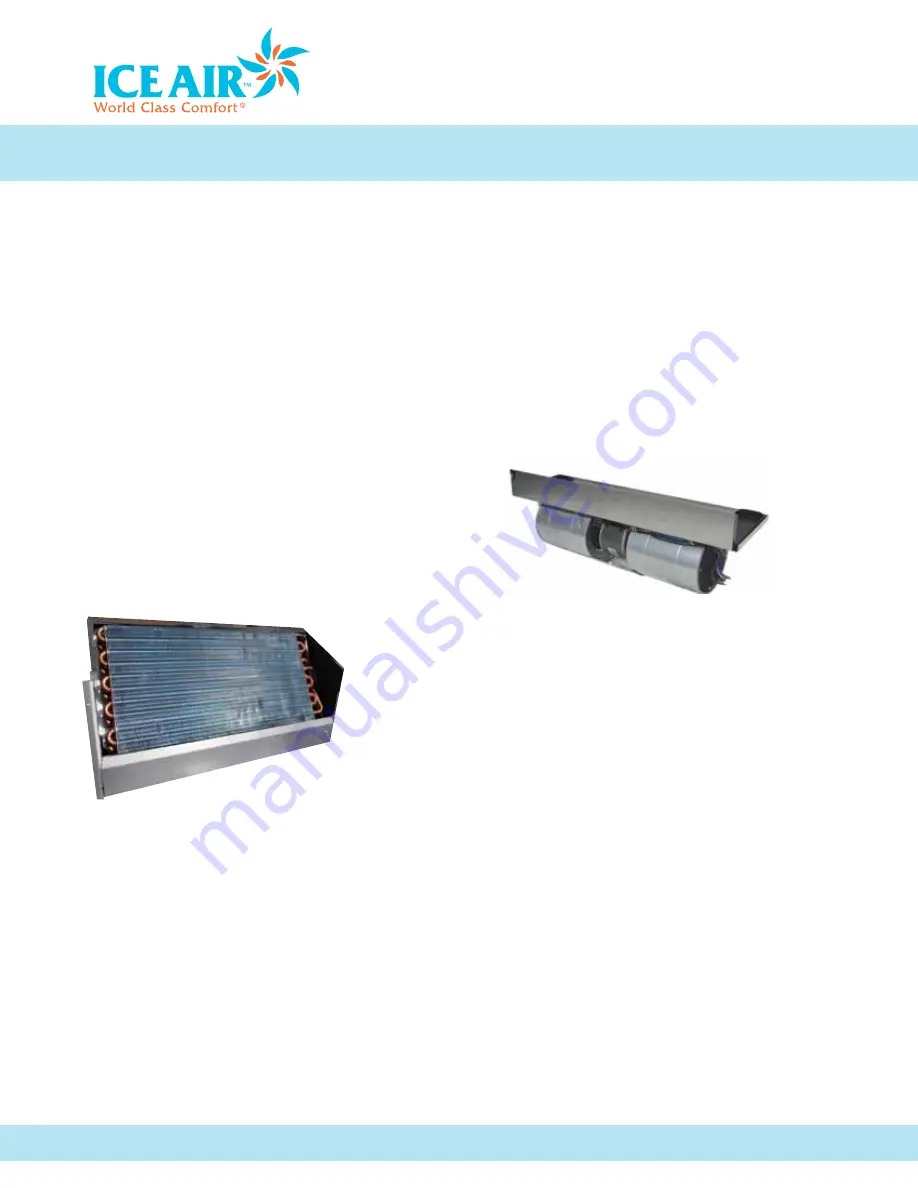

EvAPORATOR COIL

Check the coil for cleanliness and uniformity of fins.

If the coil is dirty, vacuum clean with a soft brush

attachment. This is the only form of cleaning that

should be carried out within an apartment. If the

coil requires additional cleaning, the unit must be

removed from the apartment and cleaned using

compressed air and / or washed. These operations

MUST be carried out in a facility properly equipped

to handle this type of work in a safe and professional

manner.

Drain pan / Drain HoSe cleaning

The condensate pan is located directly under the

evaporator coil. Check the visible section of the interior

of the drain pan for any buildup of dirt or condensate

water. Wash annually to remove all dirt build-up.

Check condensate drain pan for algae growth every

2 to 3 months. If algae growth is apparent, consult a

water treatment specialist for treatment. The application

of algaecide every 2 to 3 months will typically eliminate

algae problems.

DRAIN HOSE

Check drain hose for leaks and blockage to eliminate

potential problems.

EvAPORATOR MOTOR AND BLOWER ASSEMBLY

If there is evidence of dirt or dust build-up in the

evaporator motor or blowers, they should be cleaned

either by vacuum cleaning (if working in an apartment)

or by removing the unit to a workshop location and

cleaning with compressed air. Always obey safety

guidelines for using compressed air in this latter case.

Your

ICE AIR WSHP

has permanently lubricated motor

bearings that do not require additional lubrication.

Blowers and motor are factory assembled for quiet

performance – if there is any excessive noise and

vibration from this assembly, it should be serviced

by a qualified technician.