ELEVATION SERIES

CABINET CARE

15

Chemicals for Descaling and Sanitizing

It is important to use solutions that do not harm the ice machine. Never use cleaning or sanitizing solutions that

contain Nitric Acid, Sulfuric Acid, Hydrochloric Acid, Carbolic Acid, Acetic Acid, diluted Acetic Acid or non-

food-grade vinegar (concentration of acetic acid greater that 6% and does not contain enzymes created in

processing) or any chlorine-based solution such as bleach, chlorine dioxide or any type of salts such as

potassium chloride (potassium salts) or sodium chloride. Check the label or the manufacturer’s Material Safety

Data Sheet (MSDS) to be sure. These chemicals can attack the surface of the evaporator as well as other metal

components causing corrosion and flaking.

Please refer to www.iceomatic.com for approved chemical formulations and proper pH balance.

Cleaning Stainless Steel and Aluminum

Commercial grades of stainless steel and aluminum are susceptible to rusting or corrosion if not properly

maintained. It is important that you properly care for the stainless steel and aluminum surfaces of your ice

machine and bin to avoid the possibility of rust or corrosion.

Use the following recommended guidelines for keeping your machine looking like new:

1.

Clean the stainless steel and aluminum thoroughly once a week

. Clean frequently to avoid

build-up of hard, stubborn stains. Hard water stains left to sit can weaken the metals corrosion

resistance and lead to rust or corrosion. Use a nonabrasive cloth or sponge, working with, not

across, the grain.

2.

Do not use abrasive tools to clean the metal surface

. Do not use steel wool, abrasive sponge

pads, wire brushes or scrapers to clean the metal.

3.

Do not use cleaners that use chlorine or chlorides

. Do not use chlorine bleach products to

clean the metal surfaces. Chlorides break down the metals protective layer.

4.

Rinse with clean water

. If chlorinated cleansers are used, you must thoroughly rinse the sur-

face with clean water and wipe dry immediately.

5.

Use the right cleaning agent

. The table below lists the recommended cleaning agents for com-

mon metal cleaning problems.

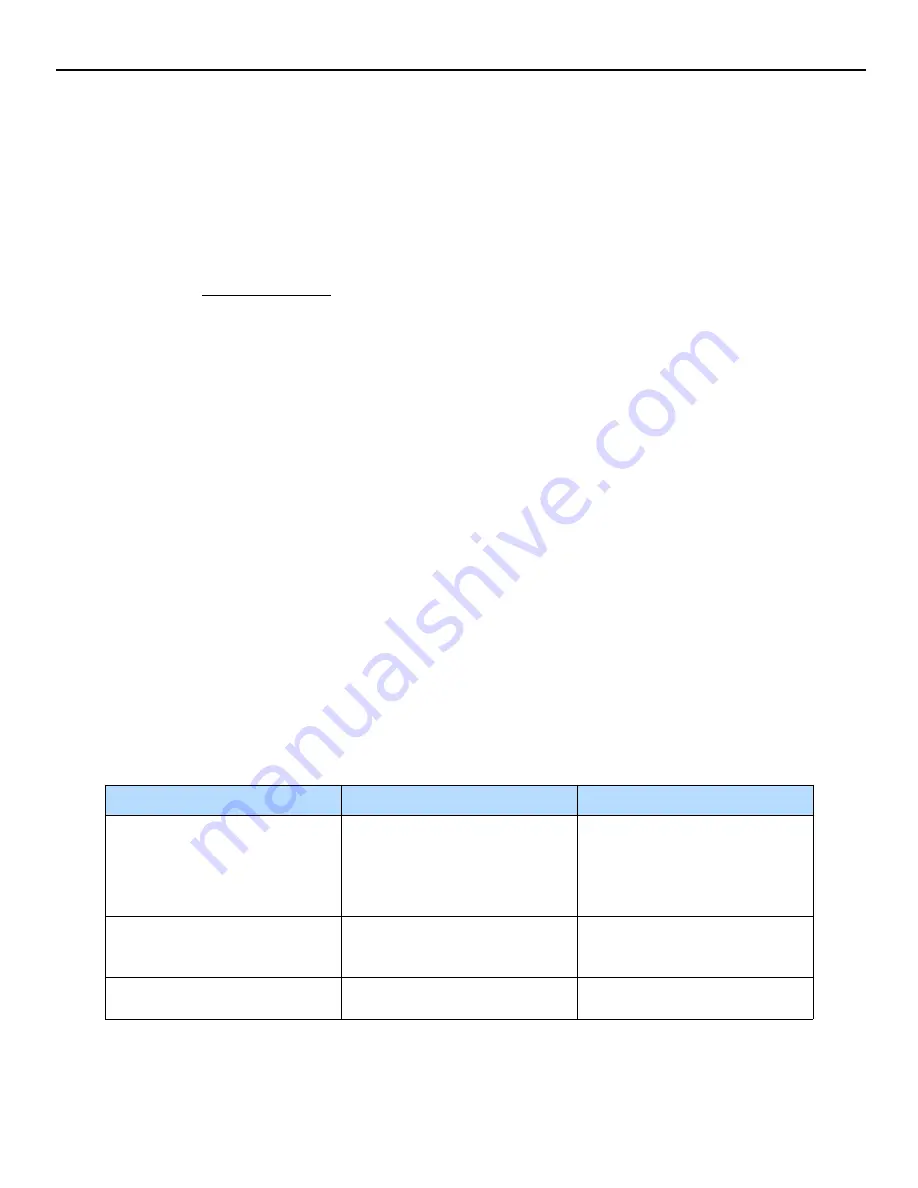

Cleaning Activity

Cleaning Agent

Method of Application

Routine Cleaning

Mild dish soap, ammonia, glass

cleaner, or mild detergent with

water. Household kitchen clean-

ing chemicals approved for metal

surfaces.

Apply with clean cloth or sponge.

Rinse with clean water and wipe

dry.

Removing grease or fatty acids

Oven cleaners

Apply generously; allow to stand

for 15-20 minutes. Rinse with

clean water. Repeat as required.

Removing hard water spots and

scale

Vinegar

Swab or wipe with clean cloth.

Rinse with water and wipe dry.