ELEVATION SERIES

CLEANING/SANITIZING PROCEDURES

65

6. Quick press the CLEAN button to start the process. Ice machine will show a solid red and flashing yellow light

during the cleaning cycle.

7. The machine will first verify that the sump is empty with the pump ON and the purge valve energized.

8. When the sump is mostly empty, the machine will begin to fill the sump (about 30 seconds to a minute).

9. The pump turns ON when the water fill reaches the proper fill level. Measure the appropriate amount of descaler

according to the machine size and sump volume from chart below. Carefully pour the descaler into the sump

using the lower curtain to prevent splash. Replace upper evaporator cover.

10. The machine will remain in the WASH cycle for 15 minutes.

11. After WASH time, the machine will PURGE and re-fill with the water pump ON.

12. The machine will RINSE (less than one minute) then repeat PURGE/FILL/RINSE multiple times.

13. The machine will end the cleaning cycle with a mostly empty sump and a solid red and yellow light.

14. Quick press the CLEAN button to return to OFF mode.

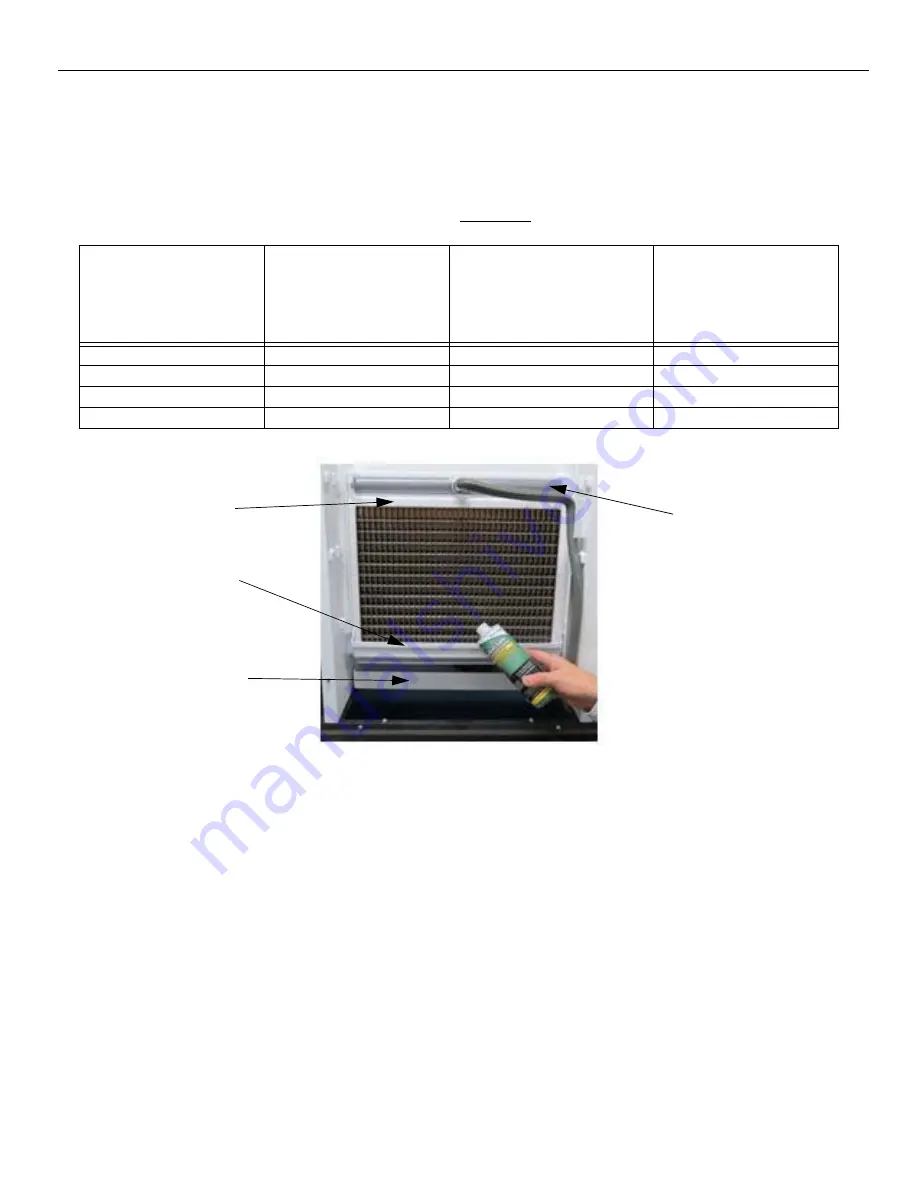

15. Remove the upper evaporator cover and lower evaporator curtain. Using a solution with the proper concentration

of cleaner (descaler or sanitizer), wipe down with a clean soft cloth the evaporator, water spillway, water

distributor, upper evaporator cover, lower evaporator curtain and all splash surfaces. Verify that all residue and

residual minerals have been removed.

16. If a full clean of water components is required, this can be done by referring to the service manual for water

system component breakdown. This is recommended to be done by a qualified service agent.

17. Re-assemble all ice machine water system components in reverse order.

18. Sanitizing the ice machine is recommended after descaling. Repeat the process with sanitizer at correct ratio.

19. It is recommended to clean (descale and sanitize) the storage means after cleaning the ice machine.

20. Quick press the POWER button to return the ice machine to the ice making cycle.

21. Replace the front panel and tighten the two panel screws with a Phillips screwdriver.

Model

Sump Size (volume)

Gallons (in liters)

Example: Nu-Calgon Nickel-

Safe Ice Machine Cleaner

Descaler Concentration Ratio

5 fl.oz. per 1 gal. of water

(39 mL per 1 Liter of water)

Example Nu-Calgon IMS-III

Sanitizer Concentration Ratio

1.6 fl. oz. per 1 gal. of water

(12.5 mL per 1 Liter of water)

CIM0320/0330

.9 (3.4)

Add 4.5 fl. oz. (133mL)

Add 1.5 fl. oz. (44mL)

CIM0430/0520/0530/0630

1.2 (4.5)

Add 6 fl. oz. (177mL)

Add 2 fl. oz. (59mL)

CIM0820/0830/1120/1130

1.1 (4.2)

Add 5.5 fl. oz. (164mL)

Add 1.8 fl. oz. (53mL)

CIM1440/1540/1840/2040

1.8 (6.8)

Add 9.0 fl. oz. (265mL)

Add 2.9 fl. oz. (85mL)

Spillway

Lower Curtain

Sump

Distribution Tube

Use Lower Curtain to direct

cleaner into Sump

Summary of Contents for CIM Series

Page 31: ...ELEVATION SERIES CIM CUBERS BOARD COMPONENT LED SEQUENCE 29 INITIAL HARVEST CYCLE AT START UP ...

Page 32: ...ELEVATION SERIES CIM CUBERS BOARD COMPONENT LED SEQUENCE 30 TRANSITION FROM HARVEST TO FREEZE ...

Page 33: ...ELEVATION SERIES CIM CUBERS BOARD COMPONENT LED SEQUENCE 31 BIN FULL CURTAIN OR STAT ...

Page 35: ...ELEVATION SERIES CIM CUBERS BOARD COMPONENT LED SEQUENCE 33 DIAGNOSTICS IN HARVEST CYCLE ...

Page 36: ...ELEVATION SERIES CIM CUBERS BUTTON FUNCTIONS 34 Button Functions ...