ICE Series

Winterizing Procedure

Page 19

Winterizing Procedures

Important!

Whenever the ice machine is taken out of operation during the winter months, the procedure below must be

performed. Failure to do so may cause serious damage and will void all warranties.

1. Turn off water to machine.

2. Make sure all ice is off of the evaporator(s). If ice is being made, initiate harvest or wait for cycle completion.

3. Place the ICE/OFF/WASH switch to the

“OFF”

position. The switch is located in the control box.

4. Disconnect the tubing between the water pump discharge and water distribution tube.

5. Drain the water system completely.

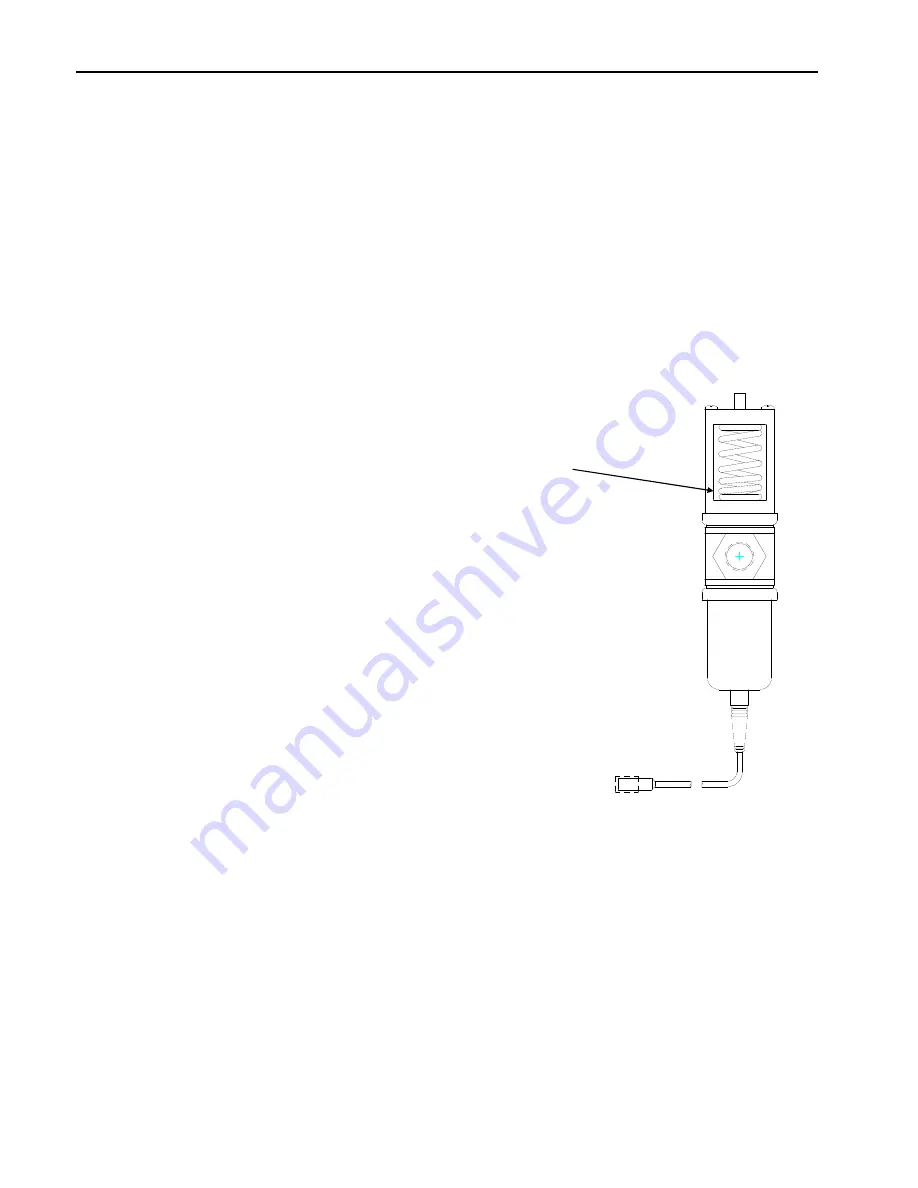

6. On water cooled machines, hold the water regulating valve open by

prying upward on the water valve spring with a screwdriver while

using compressed air to blow all the water out of the condenser.

7. Remove all of the ice in the storage bin and discard.

Summary of Contents for ICE2100 SERIES

Page 2: ... ...