FOR THE PLUMBER

CONFORM TO ALL APPLICABLE CODES

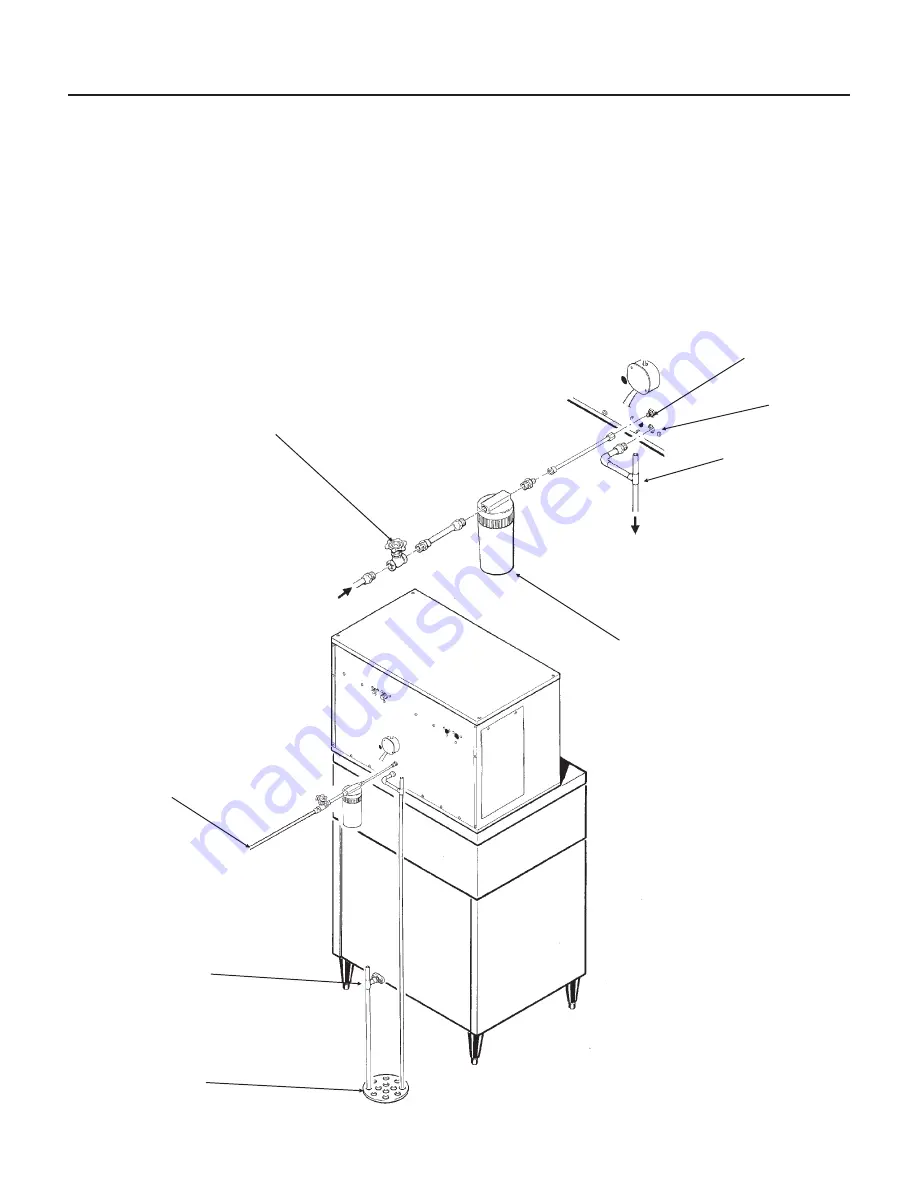

Water Supply:

The recommended water supply line is 3/8" O.D.

copper tubing, with a minimum operation pressure

of 20 PSIG, and a maximum of 80 PSIG. Connect

to cold water using the male flare connection at the

back of the machine. Install a shut off valve in an

accessible space between the ice maker and the

water supply.

Drain System:

All drains are of the gravity type, and must have a

minimum of 1/4" fall per foot of horizontal run. The

drains must be installed to conform to local

plumbing codes. The use of a vent at the machine

and at the bin will allow the system to drain

properly. Use only rigid tubing for drains; insulation

of the bin drain is recommended.

MFI2406LS

Page 5

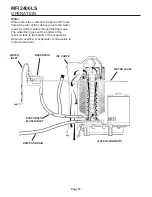

SHUT OFF

VALVE

FIELD

SUPPLIED

WATER FILTER

3/8" MALE FLARE

3/4" FPT

VENT THIS DRAIN

WATER INLET

BIN DRAIN

FLOOR DRAIN