54

TROUBLESHOOTING

TROUBLESHOOTING

This chapter lists the most common problems linked with the use of the appliance. If you are unable to resolve the problems with the

information given here, please contact your nearest assistance centre.

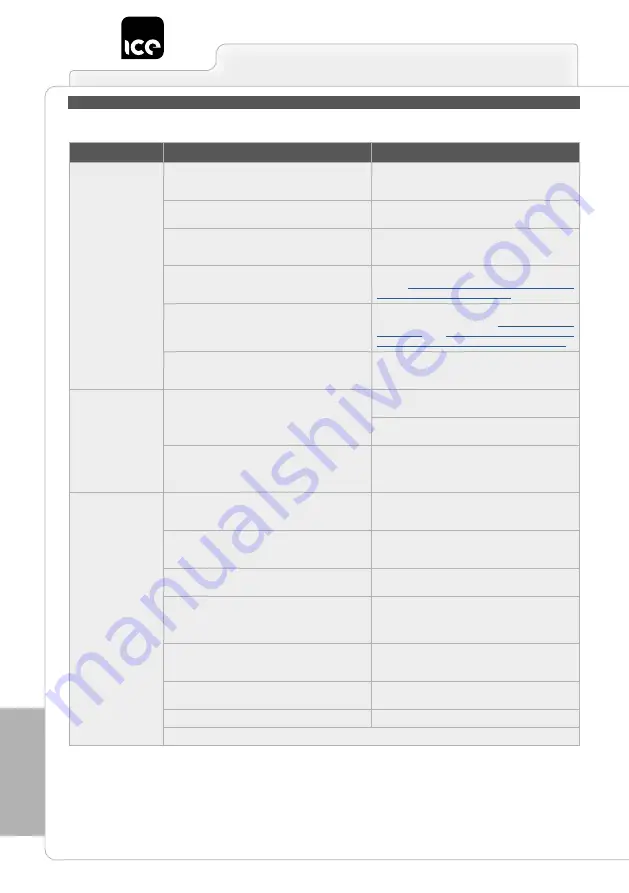

PROBLEM

POSSIBLE CAUSE

SOLUTION

THE APPLIANCE

DOES NOT SWITCH

ON

The main switch is OFF (50D versions).

Make sure the main switch is in the work position, the

LED inside it is ON, and the ON symbol is visible. If

this is not the case, press the main switch.

The main switch is in the "0" position (traction

versions).

Make sure that the main switch is at "I", if not turn the

key a quarter turn to right.

Check there are no alarm messages on the control

display when the appliance is switched on (traction

versions).

Stop the machine and contact the technician at the

service centre.

Make sure that the batteries are correctly connected to

each other and that the battery connector is connected

to the electrical system connector.

Insert the batteries into the machine (see the

section

CONNECTING THE BATTERIES TO THE

”).

Check the charge level of the batteries.

If the battery charge level is critical, perform a

complete charging cycle (read “

” or “

(VERSIONS WITH BUILT-IN BATTERY CHARGER)

Check to make sure that the appliance is not still in

its battery charging phase (versions with battery

charger).

Perform the procedure to disconnect the power cable

from the battery charger.

THE BATTERIES

DO NOT WORK

CORRECTLY

The batteries are not connected correctly

Properly connect the cable bridge, the output voltage

should be 24V.

Properly connect the battery cable connector to the

connector of the general system cable.

The terminals of the batteries are oxidized.

Unplug all cables from the batteries, clean the

battery terminals, apply a little grease and restore the

electrical connections (read the battery user manual,

the manual provided by the battery manufacturer).

THE BATTERY

CHARGER DOES

NOT WORK

The plug of the power cable is not correctly inserted in

the socket in the battery charger incorporated into the

machine (versions CB).

Check that the plug in the battery charger power cable

is connected to the socket in the battery charger.

The power supply cable plug is not correctly inserted

in the mains socket.

Check that the plug on the battery charger's power

cable is connected to the mains socket. Try another

socket if necessary.

The characteristics of the mains power supply do not

correspond to those required by the battery charger.

Check that the characteristics in the battery charger

plate are the same as those of the mains supply.

The LEDs of the battery charger blink repeatedly

(battery charger versions).

Referring to the battery charger use and maintenance

manual, check the meaning of the flashing signals that

the battery charger emits dung the battery recharge

stage.

The plug of the power cable is not correctly inserted in

the socket in the battery charger incorporated into the

machine (versions CB).

Check that the plug in the battery charger power cable

is connected to the socket in the battery charger.

The battery charger is not connected to the mains.

Connect the battery charger to a powered electrical

outlet.

The battery charger is not connected to the batteries.

Connect the battery charger to the batteries.

Check that the mains outlet is functioning properly, or that it is not a daytime socket.