Zodiac Plus Operator Manual

2-6 About the CLARiTY Operating System

Rev AA

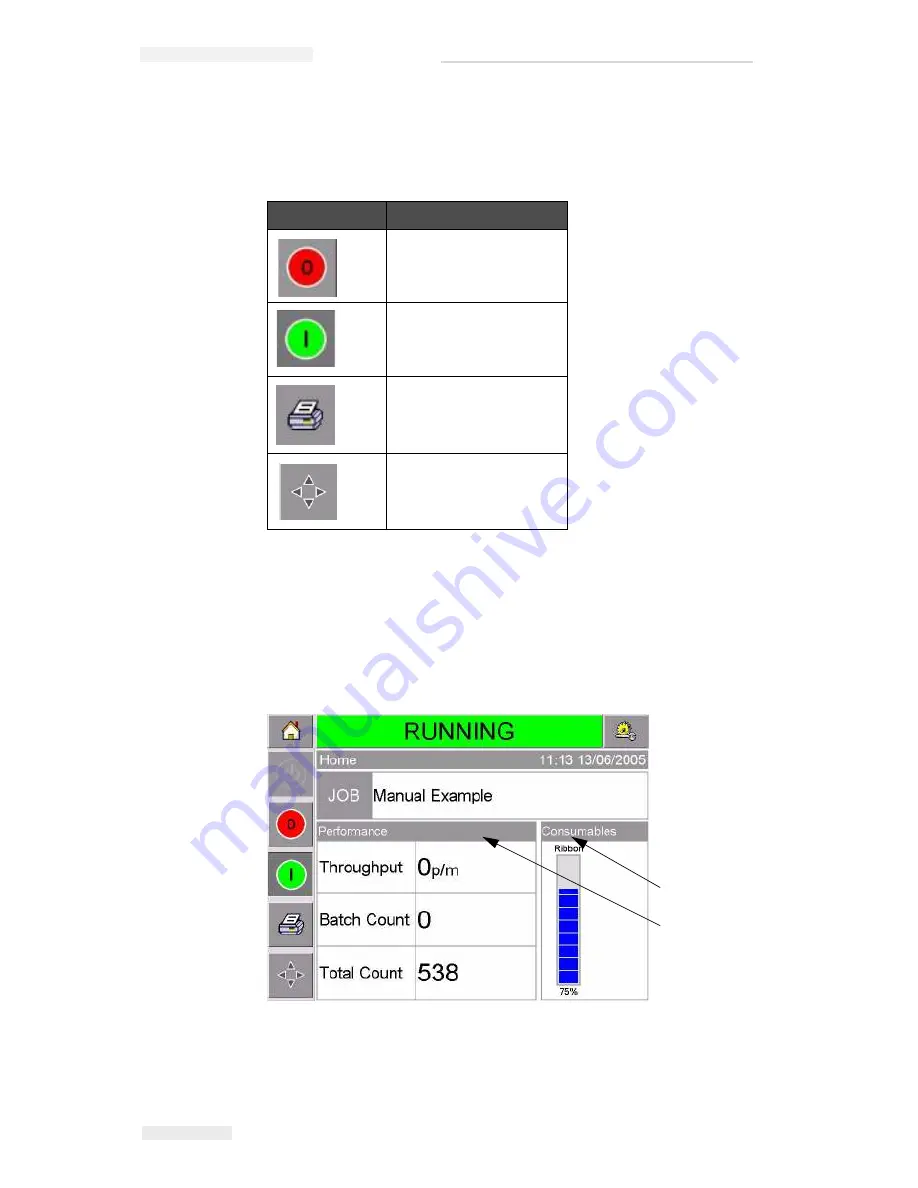

On the left side of the home screen display is the Control Frame

(Figure 2-2 on page 2-4). This contains buttons (Table 2-3) that stay

active as long as the printer is powered up. These buttons are used for

the immediate control of your printer.

The home screen contains two more buttons (Figure 2-4):

• Production Performance button

• Consumables Status button

Touch each of these areas to go to the pages that contain further details

and statistics about production throughput and ribbon status.

Button

Description

Stop

Start

Test Print

Print Registration

Table 2-3: Control Frame Buttons

Figure 2-4: Performance and Consumables Status Buttons

1

2

1. Consumables Status Button

2. Production Performance Button