15

EXISTING VENT SYSTEMS

IMPORTANT RETROFIT

VENTING INSTRUCTIONS

If this furnace is a replacement

installation,

ALWAYS INSPECT

the

existing vent system to be sure there

are no obstructions, blockages, or

signs of corrosion.

When the existing furnace is removed

from a venting system serving other

appliances, the venting is likely to be

too large to properly vent the remaining

attached appliances.

The following steps shall be followed

with each appliance that remains

connected to the common venting

system, while the other appliances that

remain connected to the common

venting systems are not in operation.

NOTE:

When the vent table permits

more than one diameter of pipe for a

connector or vent, the smallest

permitted diameter must be used.1.

Seal any unused openings in the

common venting system.

1. Seal any unused openings in the

common venting system.

2. Visually inspect the venting system

for proper size and horizontal pitch

and determine that there is no

blockage, restriction, leakage,

corrosion or other deficiencies which

could cause an unsafe condition.

3. Insofar as is practical, close all

building doors, windows and all

doors between the space where the

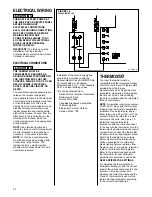

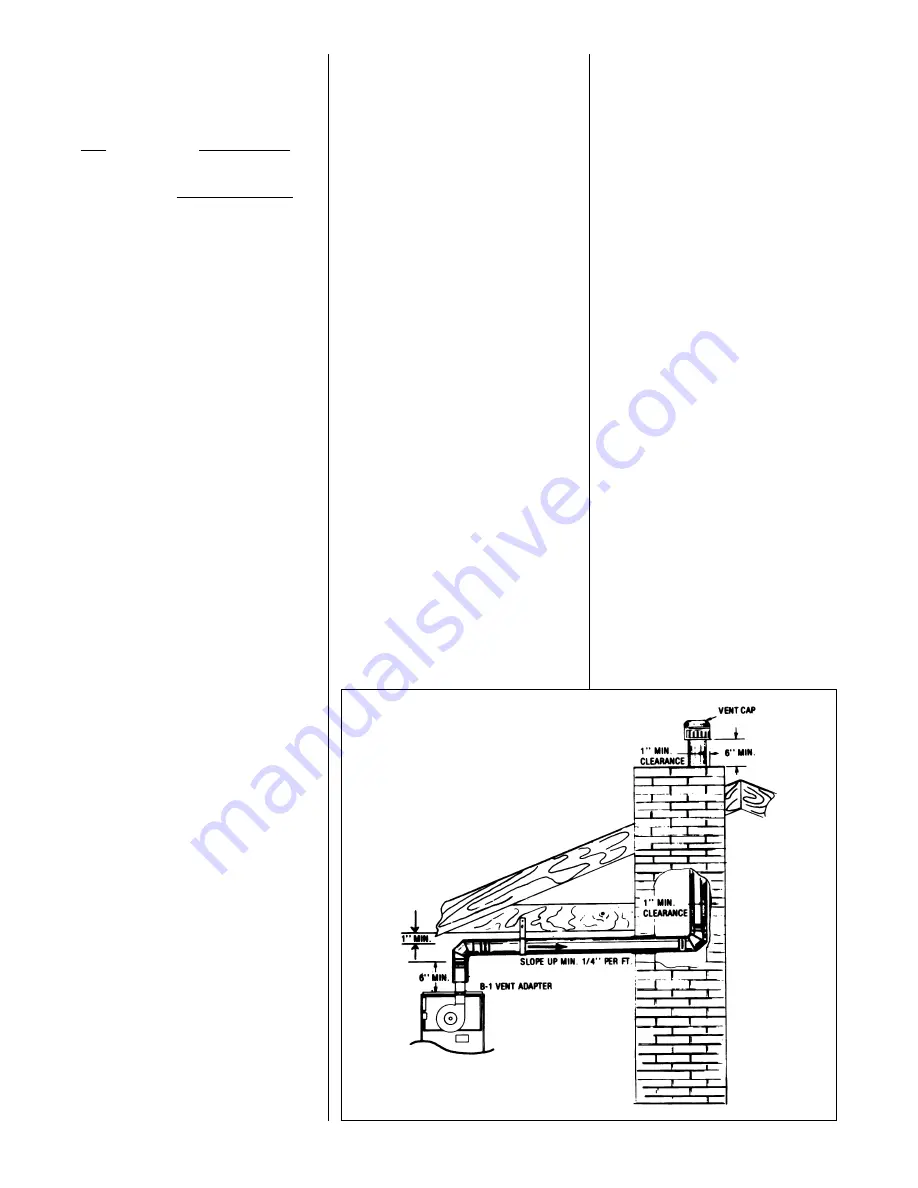

FIGURE 11

DEDICATED VENTING THROUGH

CHIMNEY WITH “B-1” VENT

appliances remaining connected to

the common venting system are

located. Turn on clothes dryers and

any appliance not connected to the

common venting system. Turn on

any exhaust fans, such as range

hoods and bathroom exhausts, so

they will operate at maximum speed.

Do not operate a summer exhaust

fan. Close fireplace dampers.

4. Follow the lighting instructions.

Place the appliance being inspected

into operation. Adjust the thermostat

so the appliance will operate

continuously.

5. Test for spillage at the draft hood

relief opening after 5 minutes of

main burner operation. Use the

flame of a match or candle, or

smoke from a cigarette, cigar, or

pipe.

6. After it has been determined that

each appliance that remains

connected to the common venting

system properly vents (when tested

as outlined above) return doors,

windows, exhaust fans, fireplace

dampers and any other gas-burning

appliance to their previous

conditions of use.

7. If improper venting is observed

during any of the above tests, the

common venting system must be

resized. Refer to National Fuel Gas

Code, ANSI Z223.1 and/or the

Natural Gas Installation Code,

CSA-B149.1 & .2.

HORIZONTAL VENTING

SPECIAL VENT SYSTEMS (SVS)

IMPORTANT:

It is THE FURNACE

MANUFACTURER’s position now that

new installations of any HTPV pipe

used in a category III vent application,

including Selkirk’s Selvent™ II HTPV

product, should cease immediately.

POWER VENT SYSTEMS

When vertical venting is not possible,

the only acceptable method for

horizontal venting is with the use of

Tjernlund model GPAK-1TR or Field

Controls models SWG-4R power

venter. Type B vent pipe and fittings

must be used. Common venting is not

permitted

All application and installation

instructions supplied with the power

venter must be followed.

Please address all questions regarding

power venter installation, agency

listings and furnace model compatibility

to:

Tjernlund Products, Inc.

(800) 255-4208 or (612) 426-2993

Field Controls L.L.C.

(800) 742-8368 or (919) 522-0214