20

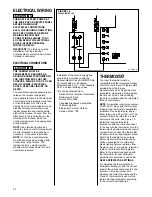

ELECTRICAL WIRING

TURN OFF ELECTRIC POWER AT

THE FUSE BOX OR SERVICE PANEL

BEFORE MAKING ANY

ELECTRICAL CONNECTIONS.

ALSO, THE GROUND CONNECTION

MUST BE COMPLETED BEFORE

MAKING LINE VOLTAGE

CONNECTIONS. FAILURE TO DO

SO CAN RESULT IN ELECTRICAL

SHOCK, SEVERE PERSONAL

INJURY OR DEATH.

IMPORTANT:

The furnace must be

installed so that the electrical

components are protected from water

(furnace condensate).

ELECTRICAL CONNECTIONS

THE CABINET MUST BE

PERMANENTLY GROUNDED. A

GROUND SCREW IS PROVIDED IN

THE JUNCTION BOX FOR THIS

PURPOSE. FAILURE TO DO SO CAN

RESULT IN FIRE, ELECTRICAL

SHOCK, PERSONAL INJURY OR

DEATH.

The electrical supply requirements are

listed on the furnace rating plate.

Use a separate fused branch electrical

circuit containing a properly sized fuse

or circuit breaker. Run this circuit

directly from the main switch box to an

electrical disconnect which must be

readily accessible and located within

sight of the furnace. Connect from the

disconnect to the junction box on the

left side of the furnace, inside the

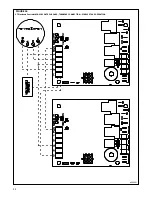

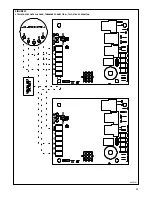

control compartment. See appropriate

wiring diagram.

NOTE:

The electrical junction box

inside the furnace control compartment

may be relocated to the right side if

necessary. A knockout is provided.

NOTE:

L1 (hot) and neutral polarity

must be observed when making field

connections to the furnace. The

ignition control on electric ignition

models will not sense flame if L1 and

neutral are reversed.

WARNING

!

WARNING

!

THERMOSTAT

The room thermostat must be

compatible with the integrated furnace

control on the furnace. All thermostats

available from the furnace

manufacturer’s Parts Department are

acceptable. Generally, all thermostats

that are not of the “current robbing”

type are compatible with the integrated

furnace control used.

NOTE:

An isolation relay (relay number

42-25104-01) may assist with “current

robbing” type thermostat compatibility

problems. Use a single-pole, single-

throw relay with a 24-volt AC coil. The

contacts should be rated for .5 amps

minimum at 24 volts. See Figure 14.

Install the room thermostat in

accordance with the instruction sheet

in the box with the thermostat. Run the

thermostat lead wires inside the control

compartment. Connect the thermostat

as shown on the wiring diagram. Never

install the thermostat on an outside

wall or where it will be influenced by

drafts, concealed hot or cold water

pipes, lighting fixtures, radiation from

fireplace, rays of sun, lamps, television,

radios or air streams from registers.

Refer to the instructions packed with

the thermostat for best anticipator

adjustment or selection or see below.

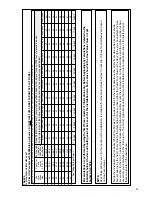

HEAT ANTICIPATOR SETTINGS

For adjusting the thermostat heat

anticipator setting; (a) add the current

draw of the various components in the

system or (b) using jumper wire,

measure the current flow between the

R and W thermostat circuits. Set the

thermostat heat anticipator according

to the current flow measured.

Installation of the electric supply line

should be in accordance with the

National Electric Code ANSI/NFPA No.

70, latest edition, or Canadian

Electrical Code Part 1 - CSA Standard

C22.1 and local building codes.

This can be obtained from:

National Fire Protection Association

Batterymarch Park

Quincy, MA 02269

Canadian Standards Association

178 Rexdale Blvd.

Etobicoke (Toronto), Ontario

Canada M9W, 1R3

FIGURE 14

ISOLATION RELAY

ST-A0804-01