E N G L IS H

2. Installation procedure

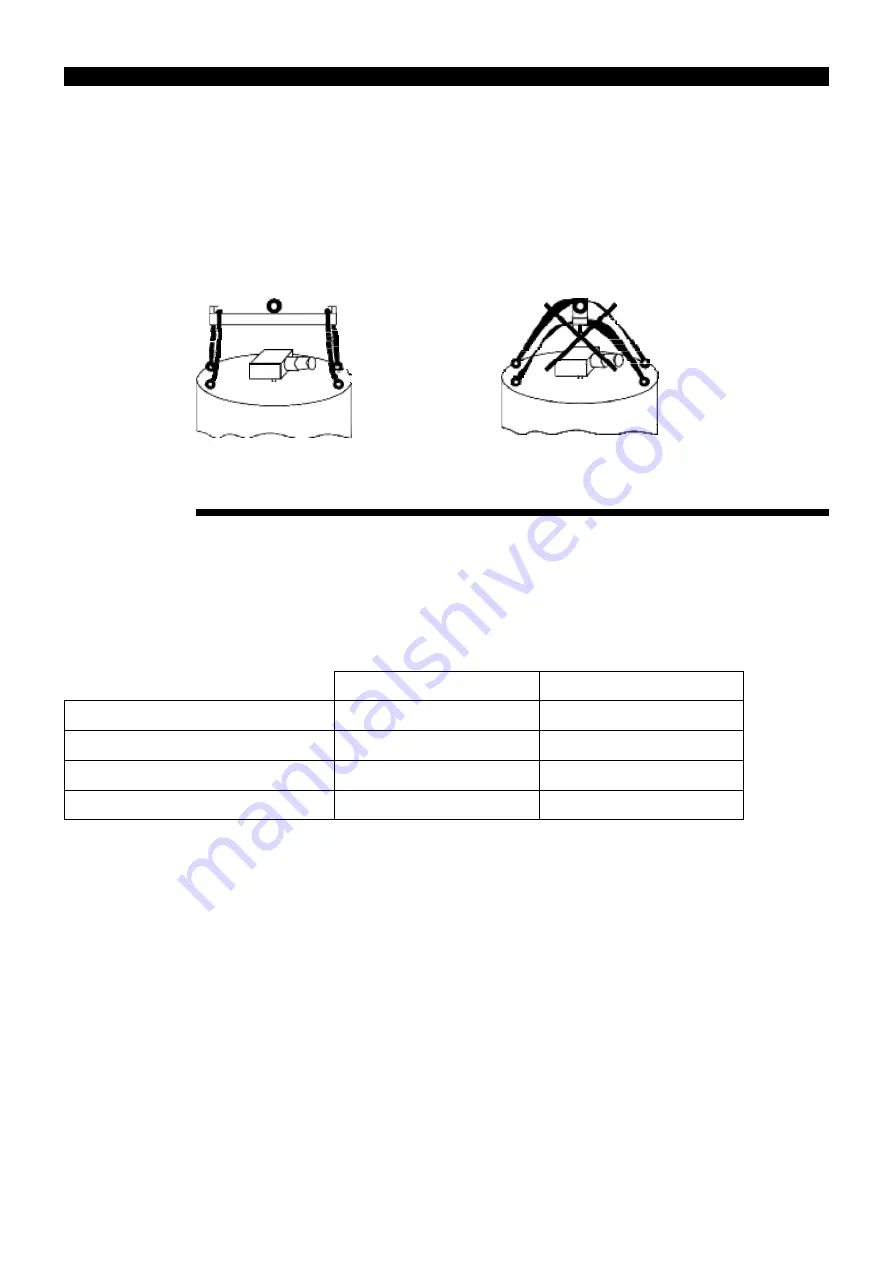

The ice-maker shall be lifted using the four shackles fixed on its base plate (for small-sized machine) or on its top (for large-sized

machine) and shall be laid down slowly on the support or ice storage bin that has been put in place.

For large-sized ice-maker, the correct steel cable lifting is as shown in this figure.

CORRECT LIFTING

WRONG LIFTING

OPERATION

1. Preliminary Checks

a) Is machine levelled?

b) Are voltage and frequency of mains supply the same as indicated on rating plate?

c) Is drainage system working properly?

Minimum value

Maximum value

Ambient temperature

5º

40º

Water temperature

5º

35º

Water pressure

1,5kg/cm2

5kg/cm2

Desviation from voltage rating

-10%

6%

NOTE:

To install a pressure reducer If water inlet pressure is more than 6 Bar.

ATENTION:

Check that voltage and mains frequency is the same as in the rating plate.

2. Starting up

Open feed water valve and fill up the water tank, and the floating valve automatically closes when water level reaches the

spillover port.

During trial operation, pneumatic mains switch (K1) shall be turned to

“ON”, then the power indicator on the panel of electrical box

(see Figure 5). Switch on the Start/Stop button on the electrical cabinet to enable the ice-maker to enter a 3-minute-delay state

(indicator of Start Delay blinks) which is followed by the automatic start of gear box and water pump by the control system, and

then the machine goes into operation. Observation shall be conducted at this time to verify that (1) ice blade is rotating in correct

direction or the shaft and rotation is in normal status; (2) water dispensing disc is aligned with the red mark and water-dispensing

pipes have normal output. In case above-stated items are all in normal operation, the Start/Stop button shall be switched off to

stop the ice machine. (3) Ice production stage: Start refrigeration system and open return air valve and Freon feed valve.

Summary of Contents for SCL 400

Page 1: ...Technical Manual Manual T cnico...

Page 5: ...E N G L IS H 3 Wiring Diagram COMPACT SCL SC...

Page 6: ...E N G L IS H COMPACT SCL SC with V f driver...

Page 7: ...SCL SPLIT SC SPLIT E N G L IS H...

Page 8: ...E N G L IS H SCL SPLIT SC SPLIT with V f driver...

Page 18: ......

Page 19: ......