32

We Think of Customer Satisfactio

n

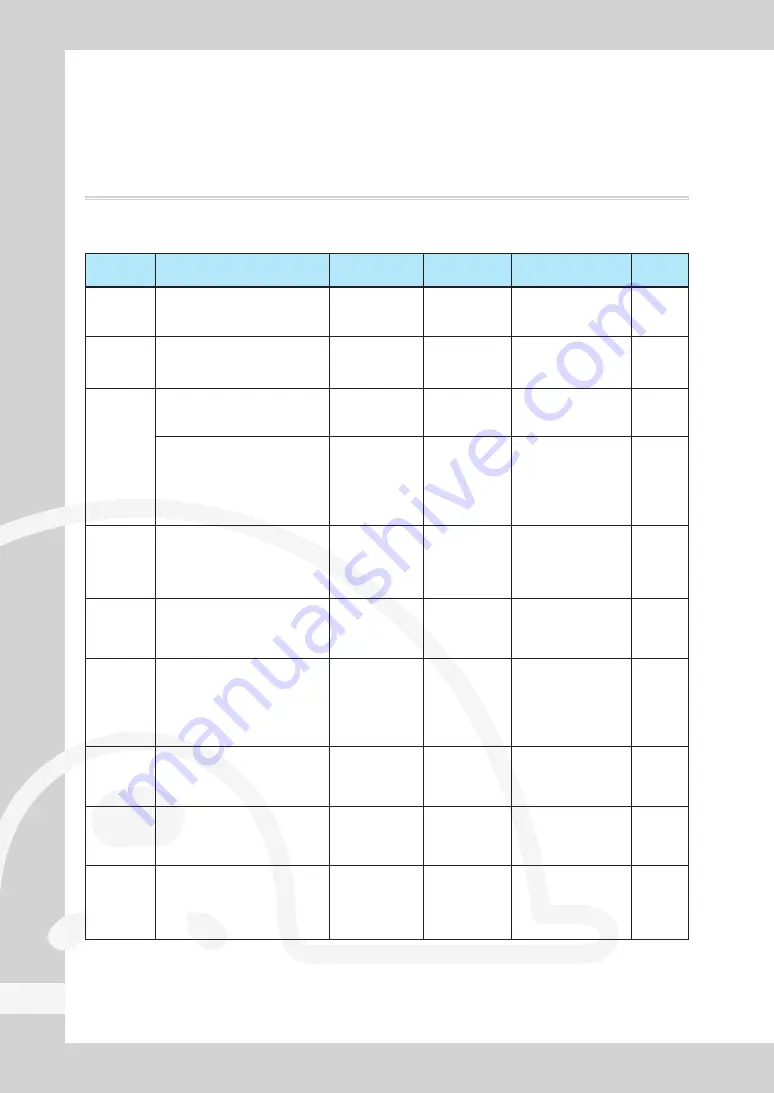

9. Error type

Type

Cause

Indicator lamp

Measures

Disabling

indication

Operation

Filled

Storage bin is filled with ice cubes.

'FULL' indicator

lights up

Use ice cubes

Automatically disabled

when the storage bin

has some room.

Stops

Water supply

error

Water for ice making is not supplied

on time.

'NO WATER'

indicator lights up

Check water

supply

Power back on when

water is supplied

Stops

Evaporator

temperature

error

Evaporator is not cooled down

properly.

'TEMP' indicator

flashes each

second

Check cooling part

(Contact

manufacturer)

Power back on when

cooling issue is resolved.

Stops

Evaporator inlet is overcooled.

'TEMP' and 'MOTOR'

indicators flash

every 2 seconds

simultaneously

Unplug and plug

back power cord

in 1 hour

(Contact

manufacturer if

error persists)

Power back on when

cooling issue is resolved.

Stops

Low

temperature

error of

condenser

Ambient temperature is too low

(Lower than 1 ℃(33.8℉))

'TEMP' indicator

flashes every 4

seconds

Operate

with ambient

temperature

above 10℃

(50℉)

Automatically disabled

when ambient

temperature goes above

10℃(50℉)

Stops

High

temperature

error of

condenser

Ambient temperature is too high or

condenser fails to cool

(higher than 75℃(167℉))

'TEMP' indicator

lights up

Check coolant

supply lines

Automatically disabled

when ambient

temperature goes above

60℃(140℉).

Stops

Motor lock

error

Motor is locked by foreign objects

inside the product.

'MOTOR' indicator

lights up

Unplug and plug

back power cord

in 1 hour

(Contact

manufacturer if

error persists)

Power back on when the

issue is resolved.

Stops

Evaporator

sensor error

Evaporator temperature sensor

malfunctions

'TEMP' indicator

lights up and

'MOTOR' indicator

flashes

Replace the

sensor

(Contact

manufacturer)

Power back on after

replacing the sensor

Stops

Condenser

sensor error

Condenser temperature sensor

malfunctions

'TEMP' indicator

flashes and

'MOTOR' indicator

lights up

Replace the

sensor

(Contact

manufacturer)

Power back on after

replacing the sensor

Stops

High pressure

error

Condenser fails to cool

'TEMP' and

'MOTOR'

indicators light up

simultaneously

Check coolant

supply lines

(Contact

manufacturer

if error persists)

Power back on after

solving coolant supply

issue

Stops