7. Before requesting for customer service

Check the following if operation of the product is not satisfactory:

If you find the operation unsatisfactory after checking, contact the local dealer or customer service center.

Provide the following details:

(Model, serial number, name of local dealer, date of purchase, and current condition of the product)

33

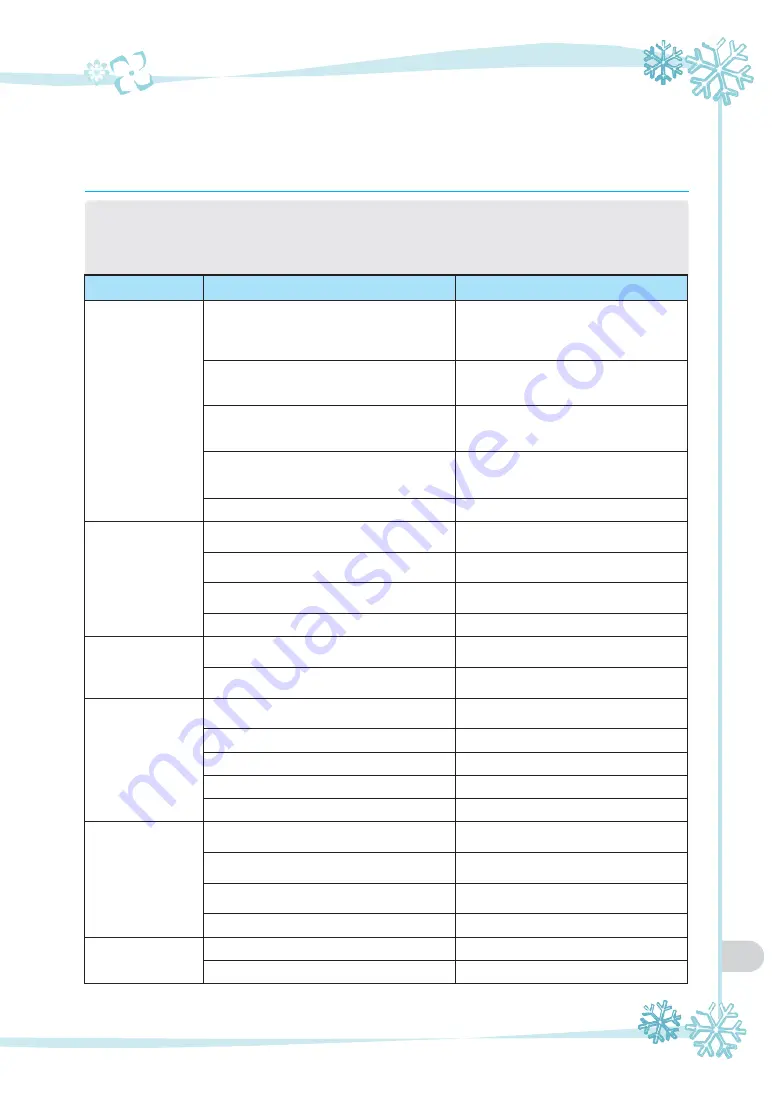

Operating Condition

Check Points

Measures

1. Machine does not

work.

1. Is the machine supplied with electric power? (Did

you plug it to the electrical outlet?)

1. Supply it with electric power.

(Plug it to the electrical outlet.)

2. Did the high pressure safety switch (red

button) at the upper back work?

2. Check the cooling water. In the

case of the air-cooled type, remove dust

from the condenser.

3. Is the power supply of the machine

using correctly?

3. Check the power supply.

Use the correct power to outlet.

4. Is the three-level switch (inside the front cover) in

the ICE MAKING position?

4. If it's in the OFF position or in the

WASHING position, change it to ICE

MAKING position.

5. WATER CURTAIN is open?

5. Check the water curtain

2. Too late ice

formation

1. The machine is too dirty.

1. Clean it using the cleaning method

described in Paragraph 6.

2. The ambient temperature is too low.

(air-cooled type)

2. Adjust the ambient temperature to

be above 50

℉

3. Dregs gathered in the cooling water

flow regulating valve. (water-cooled type)

3. Clean the valve using the cleaning

method described in Paragraphs 6.

4. The ice thickness sensor is too wide.

4. Adjust it to 0.23~0.31inches.

3. Too late ice

formation

1. Water supply is too weak.

1. Increase the water supply pressure.

Clean the filtering device (strainer) at the back.

2. The machine is too dirty.

2. Clean it using the same method

described in Paragraph 6.

4. Poor ice formation or

poor water freezing

1. The ice thickness sensor works abnormally.

1. Use the adjusting bolt to keep it

0.23~0.31inches wide.

2. The water level is too high or too low.

2. Adjust the FLOATER higher or lower.

3. FLOAT is strange.

3. Check whether it's working normally.

4. Filtering device (strainer) is stopped up.

4. Take apart the strainer at the back and clean it.

5. Operating pressure is too high.

5. Refer to 3-2).

5. Too small quantity of

ice production

1. Water is too dirty.

1. Clean it using the same method

described in Paragraph 6.

2. Water is in short supply.

2. Check the water supply pressure or whether

water supply has beensuspended.

3. The condenser is dirty.

3. In the case of the air-cooled type ondenser,

clean the aluminum fins at the back.

4. The ambient temperature is too high.

4. Adjust the ambient temperature to be below 100

℉

6. Water stagnant in the

storage container

1. The drain opening is higher than the container.

1. Install the drain opening lower than the container.

2. The drain opening is stopped up.

2. Clean the hose.

Summary of Contents for IM/WM-0460-AC

Page 34: ...MEMO 34...

Page 35: ...MEMO 35...

Page 36: ...Online Internet Service http www icetrousa com 3240288 05...