27

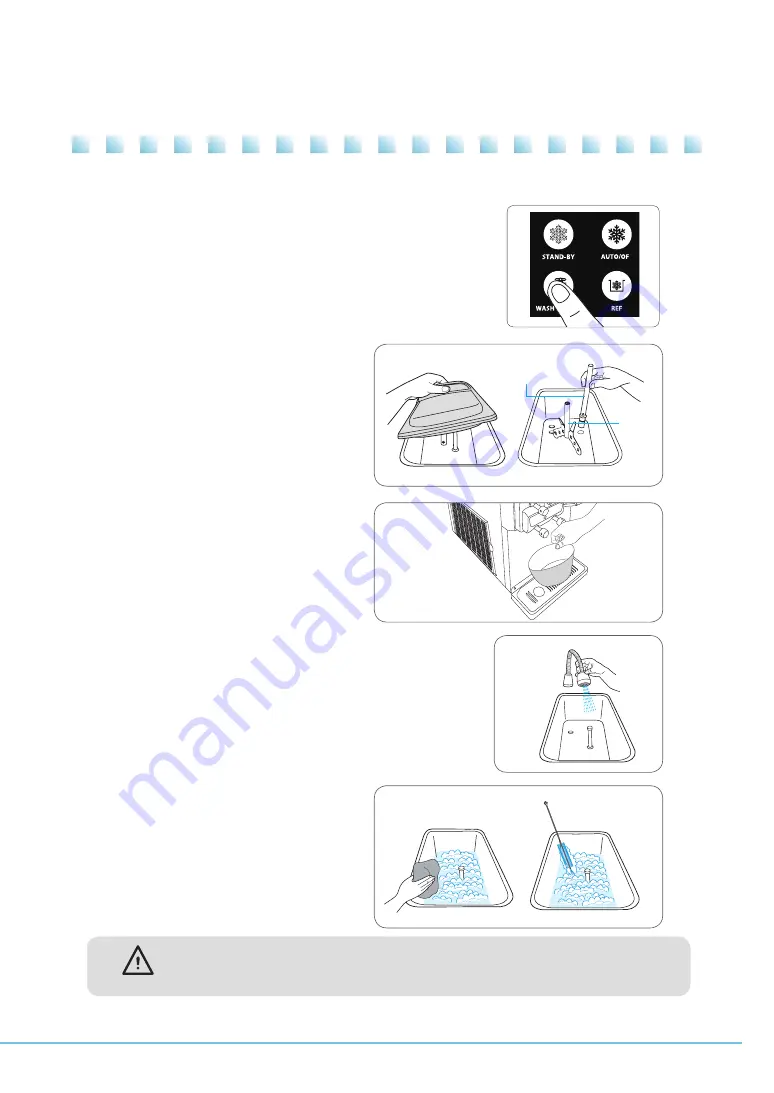

1. Press the wash button on the control panel.

(Wait until the soft cream in the cylinder is melted,

About 10 minutes.)

The carburetor, impeller, and ice cream discharge port shall be cleaned once a day.

caution

How to clean

impeller

4. Remove all liquid ingredients in the hopper,

pour some tap water, and then drain the water

a couple of times until you get clean water.

3. Put the draining basin on the drain box.

2. Open the cover of the mix hopper

and remove the carburetor and impeller.

5. For any ingredient residue around

the agitating axis, draining hole,

and height sensor, use neutral detergent

and brush and apply cleaning as well.

carburetor

PAS

TEU

RIZE

DEF

ROS

T

AUT

O

WA

SH

STO

P

STA

ND-

BY

PAS

TEU

RIZE

STA

ND-

BY

MIX

-LO

W

RE

GEN

ERA

TIO

N

DEC

.

SET

INC

.

SEL

ECT

Summary of Contents for ISI-300TA

Page 36: ...36 Circuit diagram ...

Page 39: ...39 MEMO ...

Page 40: ...3240342 01 Online Internet Service http www icetro com ...