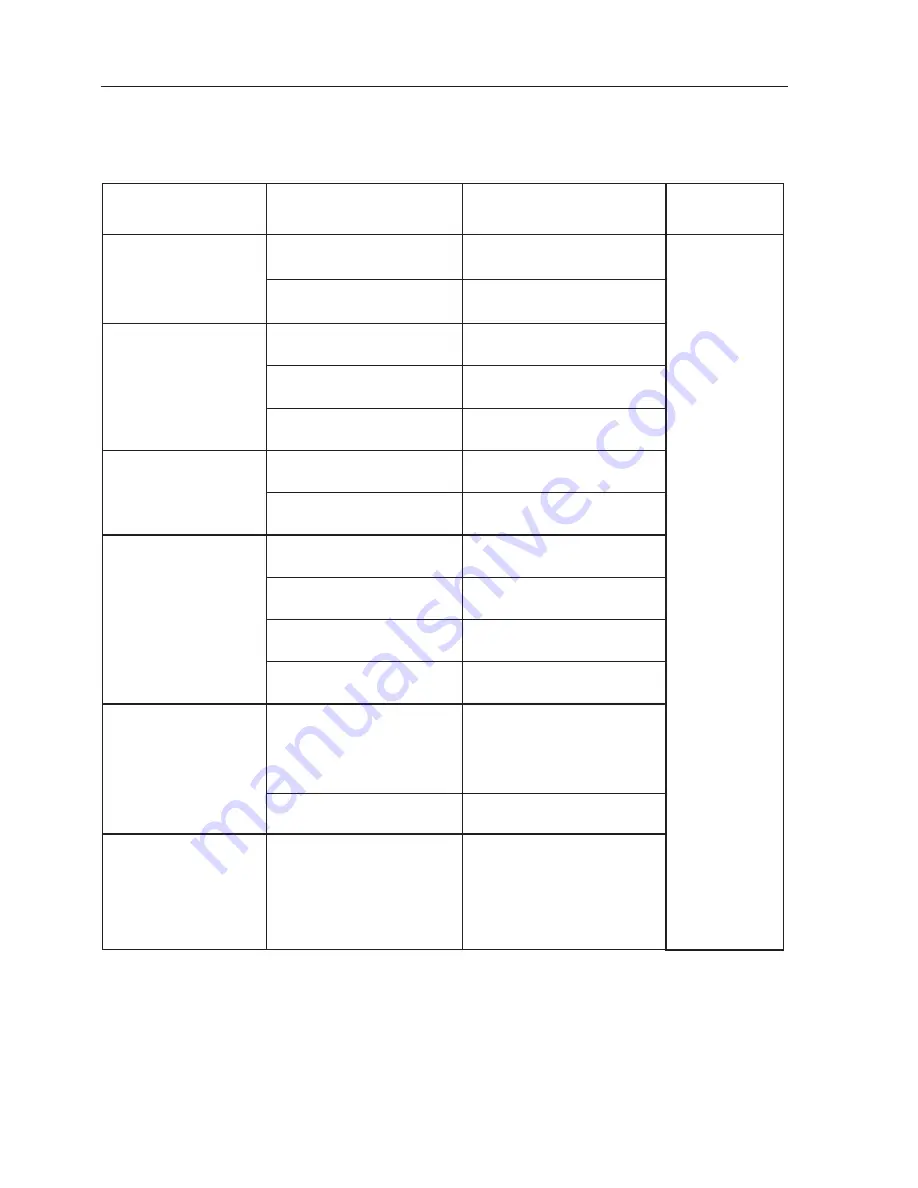

6 Troubleshooting and Warning Lights

Commonfault

Reason

Solution

Remarks

iCleaner-120

doesn't work

Weak pumping

iCleaner-120 is

turning to one side

when it moves

iCleaner-120

will not climbs

wall

iCleaner-120

will not sink to the

bottom of the pool

Dirt is coming

through the

guide vane.

The socket is

not plugged in

Connection is wrong

Impeller is

jammed or dirty

Impeller is damage

Filter Bag is full

Synchronous Belt is loosen

or broken at one side

The Filter Bag is full

Filter Bag is full

Synchronous

loosen or broken

Belt is

Sponge wheel wear

axis sleeves wear

The sponge wheel

don't soak enough

It has air inside

the machine

Belt of Filter Bag is

loosen or broken.

Dirt is too fine for

the filter bag

Plug in the power lead

Check the connection

clean the Impeller

Replace the Impeller

clean the Filter Bag

replace the

Belt

Synchronous

Clean Filter Bag

clean the Filter Bag

replace the

Belt

Synchronous

Replace the

Sponge wheel

replace axis sleeves

Wobble iCleaner-120 and

make sure air released

Replace broken filter bag

Please turn

off the power

before you

perform any

maintance

on the

iCleaner-120

- 17 -

you must hold cleaner

in water and make sure

sponge wheel soak enough,

normal time is

about 5 -15 minutes

Note: The Power Box MUST BE DISCONNECTED from the power supply prior to

conducting any maintenance on the iCleaner-120. Contact your local distributor, or place of

purchase for problems not covered in Trouble Shooting Guide.

Summary of Contents for iCleaner-120

Page 1: ...120 ...

Page 5: ... Power Box Parts 4 ...