Installation

29

NOTE

These values are valid assuming the presence of a thermal deaerator. In the absence of the deaerator, it is appropriate, however,

to raise the temperature of the water contained in the tank to at least 80°C to reduce the content of dissolved gas (O

2

and CO

2

).

It is, in any case, appropriate to use chemical conditioning to de-oxygenate the water supply completely and to minimise the

corrosive CO

2

effects.

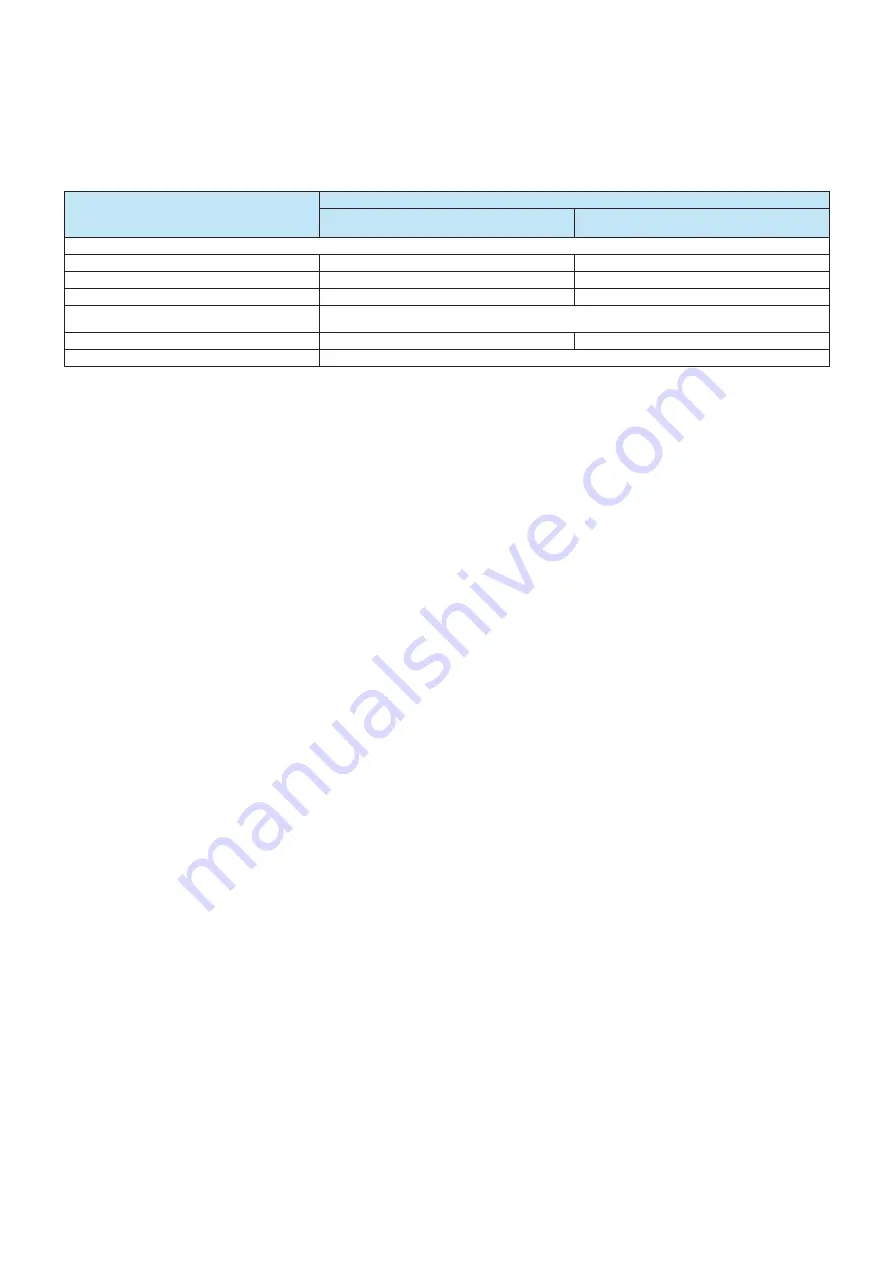

5.2 Operating water - threshold values

CHARACTERISTICS

u.m.

Steam generator water with pressure up to 20 bar

Direct conductivity of the supply water > 30

μS/cm

Direct conductivity of the supply water ≤30

μS/cm

Appearance

Clear, limpid, without foam or suspended solids

Direct conductivity at 25°C

μS/cm

< 6000

[a]

< 1500

pH at 25°C

---

10,5 - 12

10 - 11

[b]

[c]

Composite alkalinity

mmol/l

1 - 15

[a]

0,1 - 1

[c]

Silica (SiO

2

)

mg/l

See the previous table "Maximum acceptable silica content in the boiler generator water up to 20 bar

pressures"

Phosphates (PO

4

)

[e]

mg/l

10 - 30

6 - 15

Organic substances

-

See note

[d]

[a]

With a superheater consider as maximum value 50% of the value indicated as maximum.

[b]

Basic pH adjustment by injecting NaPO

4

, further injection of NaOH only if the pH value is < 10.

[c]

If the acid conductivity of the generator feed water is < 0.2 μS/cm, and its concentration of Na + K is <0.01 mg/l, the injection

of phosphate is not required. It can be applied under AVT conditions (treatment with volatile chemicals, feed water pH ≥ 9.2 and

generator water pH ≥ 8), in this case the conductivity of the generator water is < 5 μS/cm.

[d]

If treatment with coordinated phosphate is used, considering all other values, higher concentrations of PO

4

are acceptable.

[e]

Organic substances are generally a mixture of various different compounds. The composition of such mixtures and the

behaviour of their individual components under the generator operating conditions, are difficult to predict. Organic substances

can be decomposed to form carbonic acid or other acid decomposition products that increase acid conductivity and cause

corrosion and deposits. They can also lead to the formation of foam and/or production of steam with suspended water, that must

be kept as low as possible.

FREQUENCY OF ANALYSIS

The frequency of the analysis must be carried out according to the table in the periodic verifications paragraph. However, it is

advisable to check the pH value, the total hardness and the alkalinity of the feed and operating water. It is good practice, especially

under variable operating conditions, to monthly submit a significant sample of the feed and operating waters for complete

analysis. It is also good practice to visually check the condensate returns for any highly polluting oily substances (reduction of

evaporation on the surface of generator water due to a layer of oil).

Cooke Industries - Phone: +64 9 579 2185 Email: sales@cookeindustries.co.nz Web: www.cookeindustries.co.nz