Installation

20

For

250

,

320

,

420

,

555

,

700

,

780

,

850

models, the door opening can be inverted as follows.

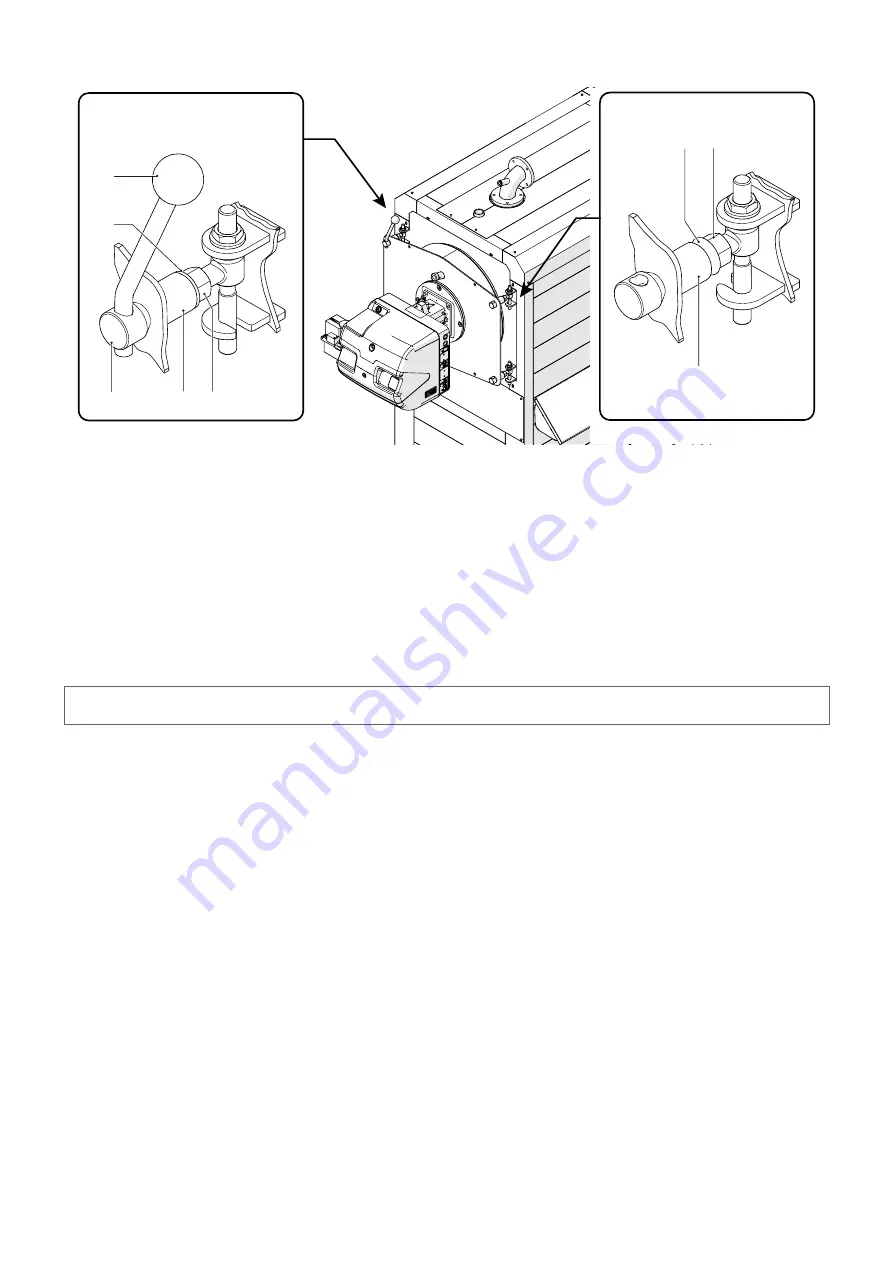

Dx

Sx

2

4

1

5

3

7

6

8

Left hinge:

–

screw the ring nuts (1) of the left side with the lever (2) in such a way that the distance of the door from the appliance front

plate is the same and the sealing gasket is uniformly pressed.

–

screw the nuts (3), of the left tie-rods, until the conical washers (4) are inserted into the door mechanical tubes (5). Properly

tighten the nuts (3).

Right hinge:

–

loosen the nuts (6) and disengage the conical washers (7) from the door mechanical tubes (8).

DOOR ADJUSTMENT

a

DANGER

Incorrect door adjustment with consequent damage to people and property voids the warranty conditions.

The door of

120

,

140

and

180

model requires, if necessary, only the adjustment of its height.

To make the adjustment:

–

remove the nuts (1) fastening the door

–

unscrew the locknut (2) WITHOUT REMOVING IT

–

work on the adjustment nut (3) to lift or lower the door, centring the gasket on the appliance front plate (4) and lock the

locknut (2)

–

refit the four nuts (1), previously removed, and lock them by tightening them diagonally.